The modeling technique is

hugely responsible for the level of productivity. Those of you that

are only trained in the constrained sketching world of the major CAD

systems

are truly limited by not using the freedom of Streamlined Sketching

and Feature Based Design,

that is available in even the most Pro/e-ish of CAD systems. If you

or your

designers are designing in these very unproductive and time

consuming processes it might be time to review your standard design

processes. Don't have any do you?

These

lessons started out as

product comparisons, but quickly turned into a study in 3D modeling

techniques.

I am not sure if it is due to these

exercises but I have replaced a few Creo, Solidworks and Fusion 360 with ZW3D. Listen to

what these two fellows said.

Brian

"We spoke a year and a

half or so ago about ZW3D. I took the Autodesk Fusion

360 but am becoming increasingly unhappy with it… It’s not very

productive for me, just too slow and cumbersome to get things done

quickly. On on the strength of your recommendations I am ready to

give ZW3D Standard a shot, probably as a rental for the first year.

Bottom line is,

Fusion 360 is “free” but not really free… I am finding that the

slow, clumsy pace of design with it is counterproductive… time is

money."

Thanks much,

Brian

Peter

The initial hull design was done in Rhino, which for some reason

is a standard in the boat industry.

The surface already had

a few problems!

It was imported into Fusion 360 and I did

some of the early concept design work, but when it came to surfacing

I hit road blocks every way I tried it.

At this time Phil

was not part of the project, but I suggested to my client that we

needed Phil's help. Phil also hit road blocks in Fusion 360 even

using some of his unique re-topologizing workflows and T-Splines.

The rest is history, as they say.

Thanks to ZW3D

paired with Phil’s surfacing skills we now have tooling for the hull

created.

You should see the images.

Perfectly smooth

reflections!

Peter

I saw the

following Solid Edge YouTube tutorial and thought I would give it a

try on IronCAD. I have to tell you it is almost tortuous to watch

the Solid Edge presenter. I

have tried to do top down design in Solidworks and failed. Inventor

is a bit better but all of these programs including Solid Edge

create external parts. You will see a huge difference in ZW3D's

multi-object design environment.

You can see the same basic part

done on NX. The part is dimensioned incorrect in the Solid Edge

drawing.

ZW3D vs NX

Solid Edge is a constrained sketched based

system as are Fusion 360, Solidworks and Creo. In the following

lessons you can see that this modeling paradigm is use throughout

the industry causing millions of wasted hours.

3D Modeling Techniques Defined

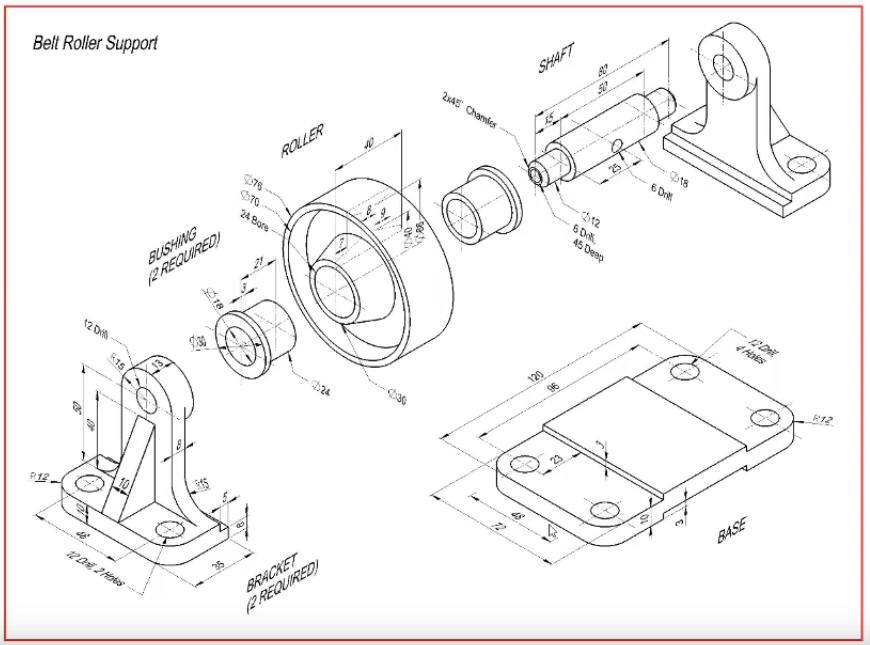

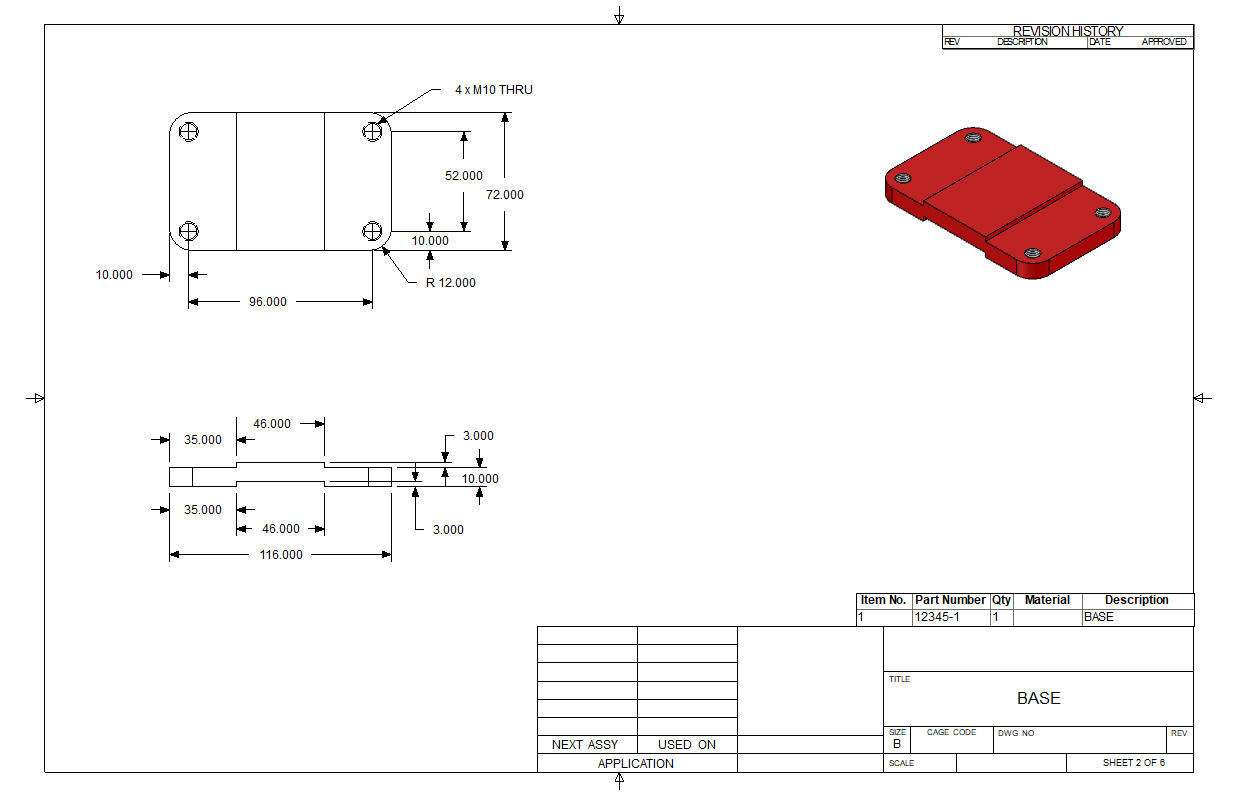

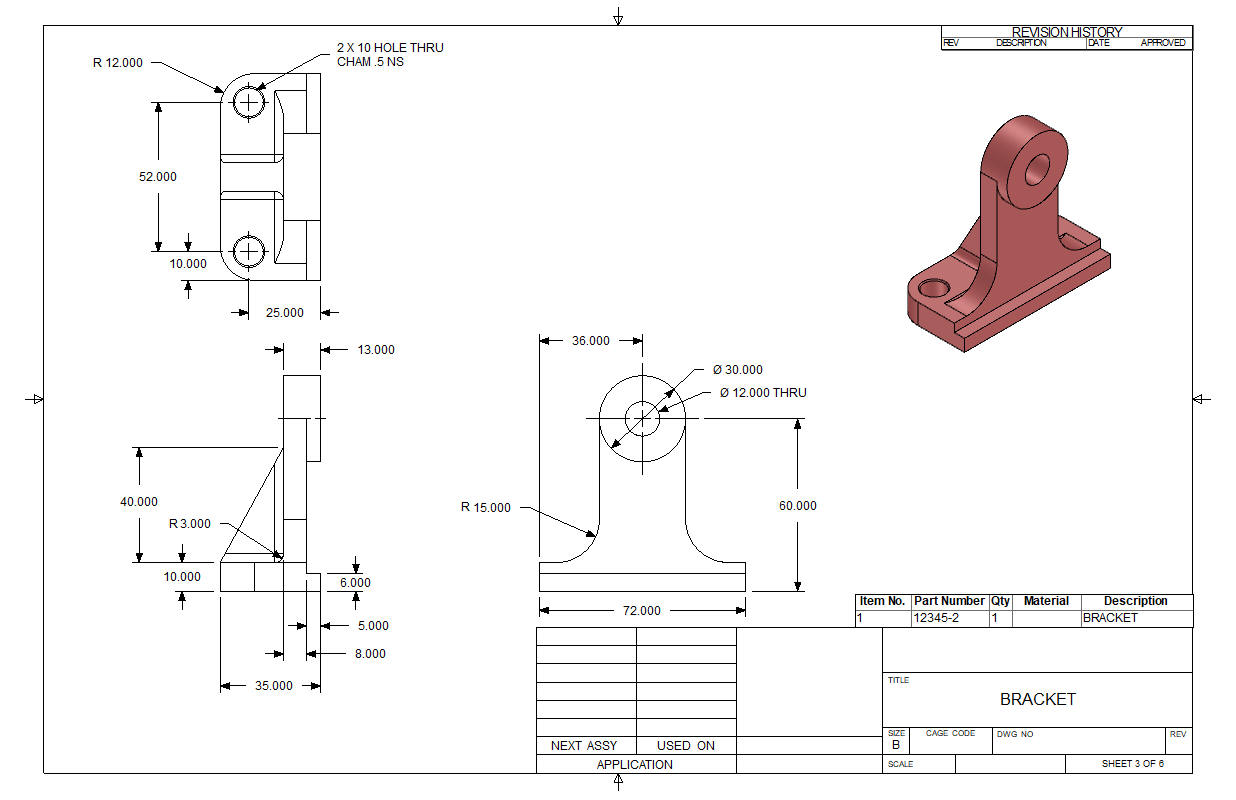

Here is the Isometric drawing. It is incorrect. So use the drawings

at the end for a good assembly. The top boss on the base should be

46mm.

While creating 3D models from a drawing is the very best way to

learn 3D CAD and maybe some design techniques is does not expose the

designer to the design flexibility necessary in product design. ZW3D is all top down due to the

multi-object design environment.

Creating mating parts is a cruise. But modeling is just one aspect of a

well designed productive 3D CAD system.

ZW3D vs Solid Edge

ZW3D is very similar to

Solid Edge and the Pro/e

clones with differences that make it much more streamlined. It is very easy for those users

to get up and running with ZW3D. The unique benefits over the other systems

is the multi-object environment with the integrated drawing. You can

do complete projects (parts, assemblies and drawings) in one file.

I would do a

video, but I really am not good at it. So I will show you step by

step. I will try and get ZW3D support to create one. They are

very good.

ZW3D is a history based

system with planes, but it also has primitive shapes to increase

your productivity. It seems to me watching this Solid Edge

exercise that there is no concern for simplifying the process and

increase design productivity. Most of us do engineering design and

have schedules to meet. Not only do these more productive modeling

techniques and a productive system increase design speed it allows

us to meet our goals much easier. Especially with changes.

I

have to say this is incredibly simple. But the Solid Edge presenter has been

indoctrinated into these designs time consuming modeling techniques. The Solidworks clones are costing the industry millions, if not billions,

in lost productivity.

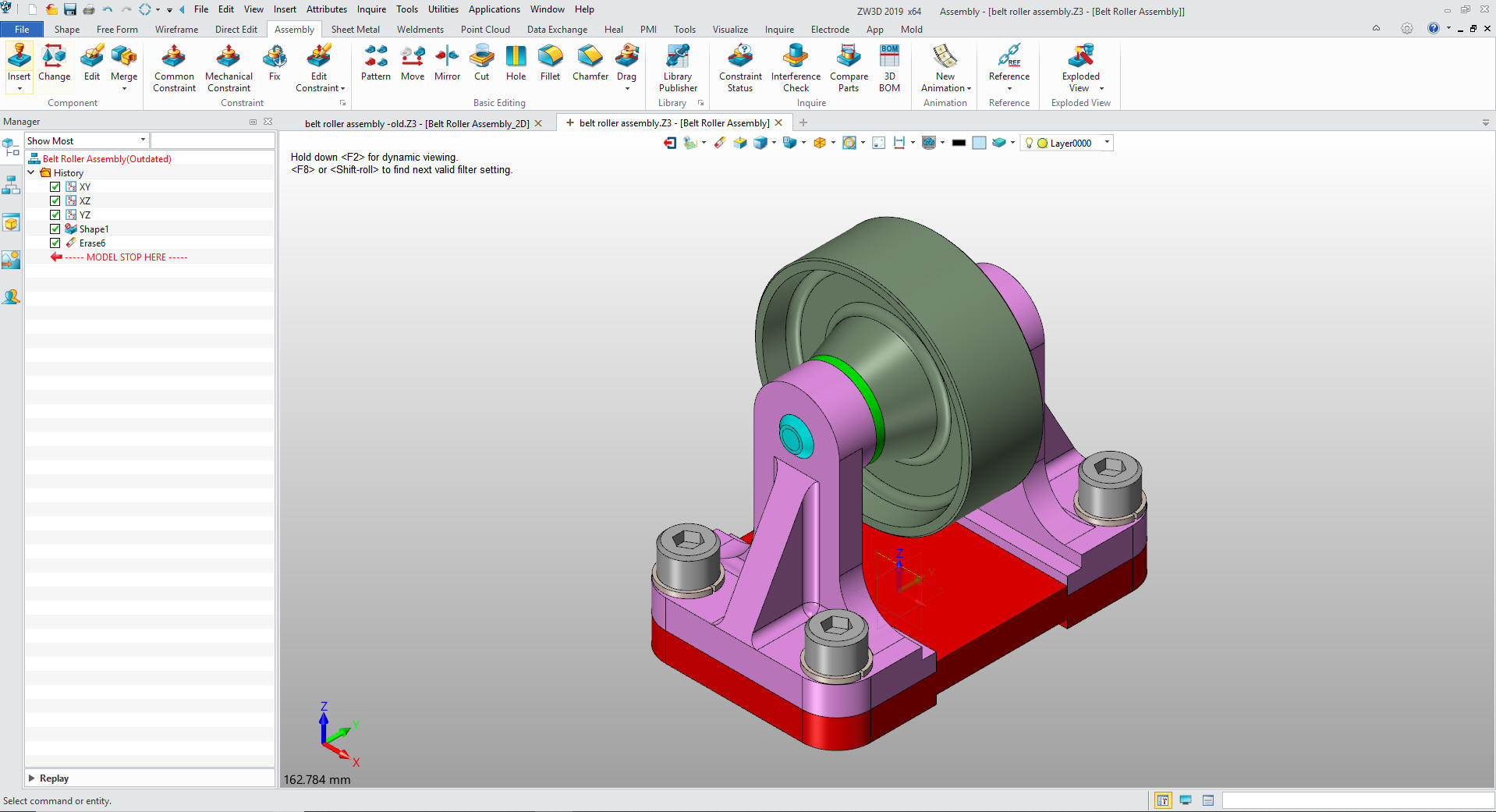

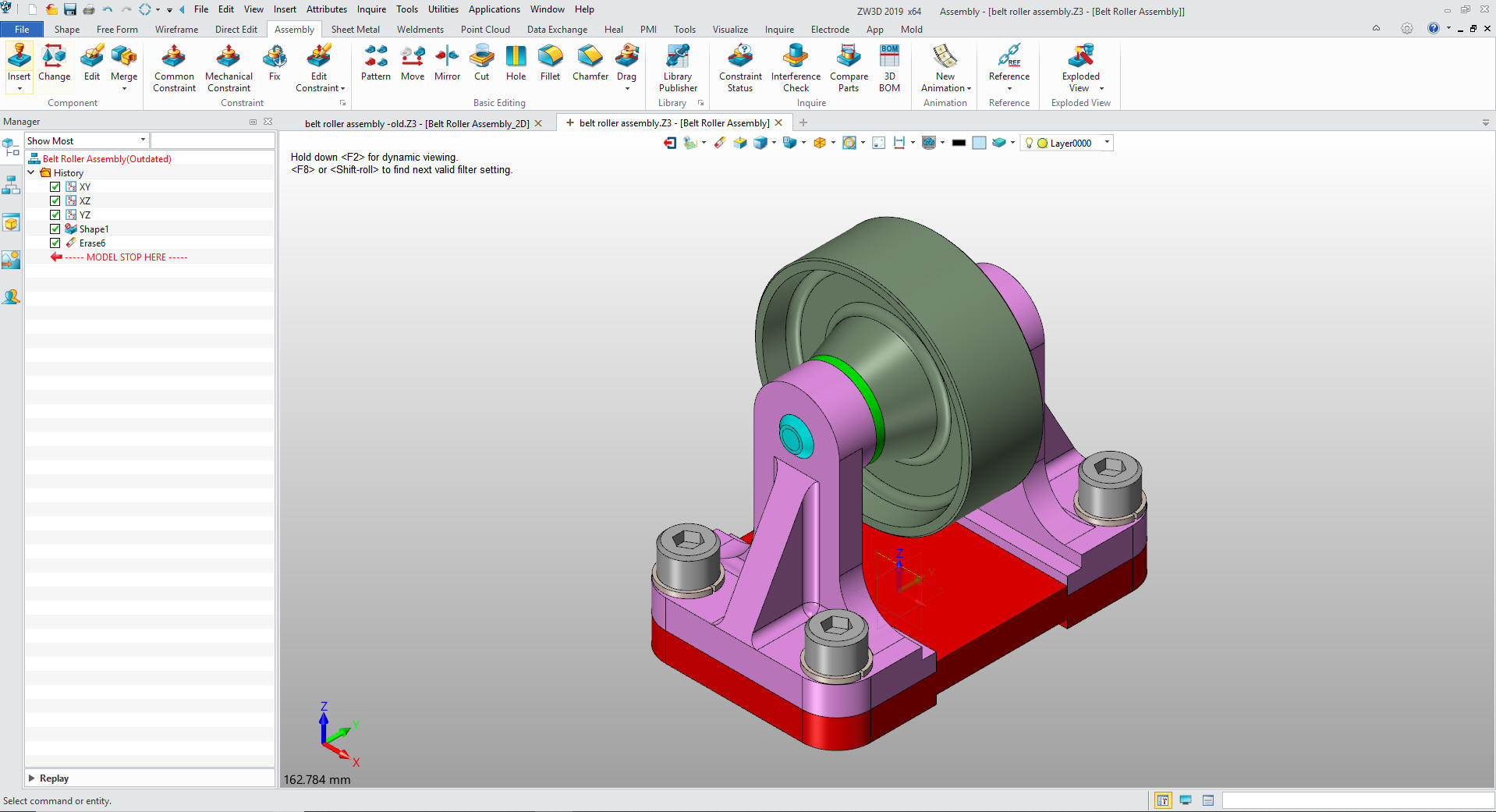

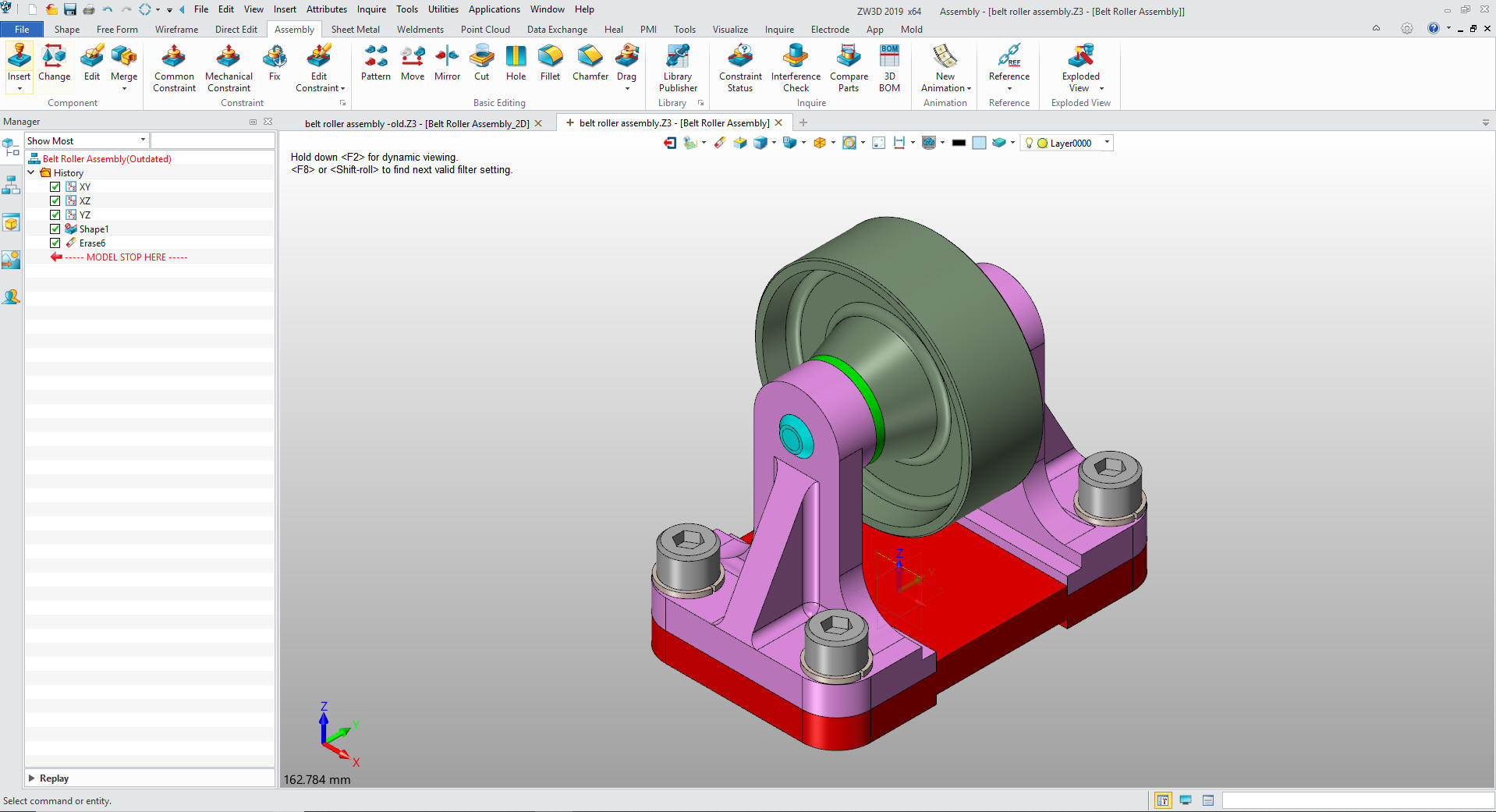

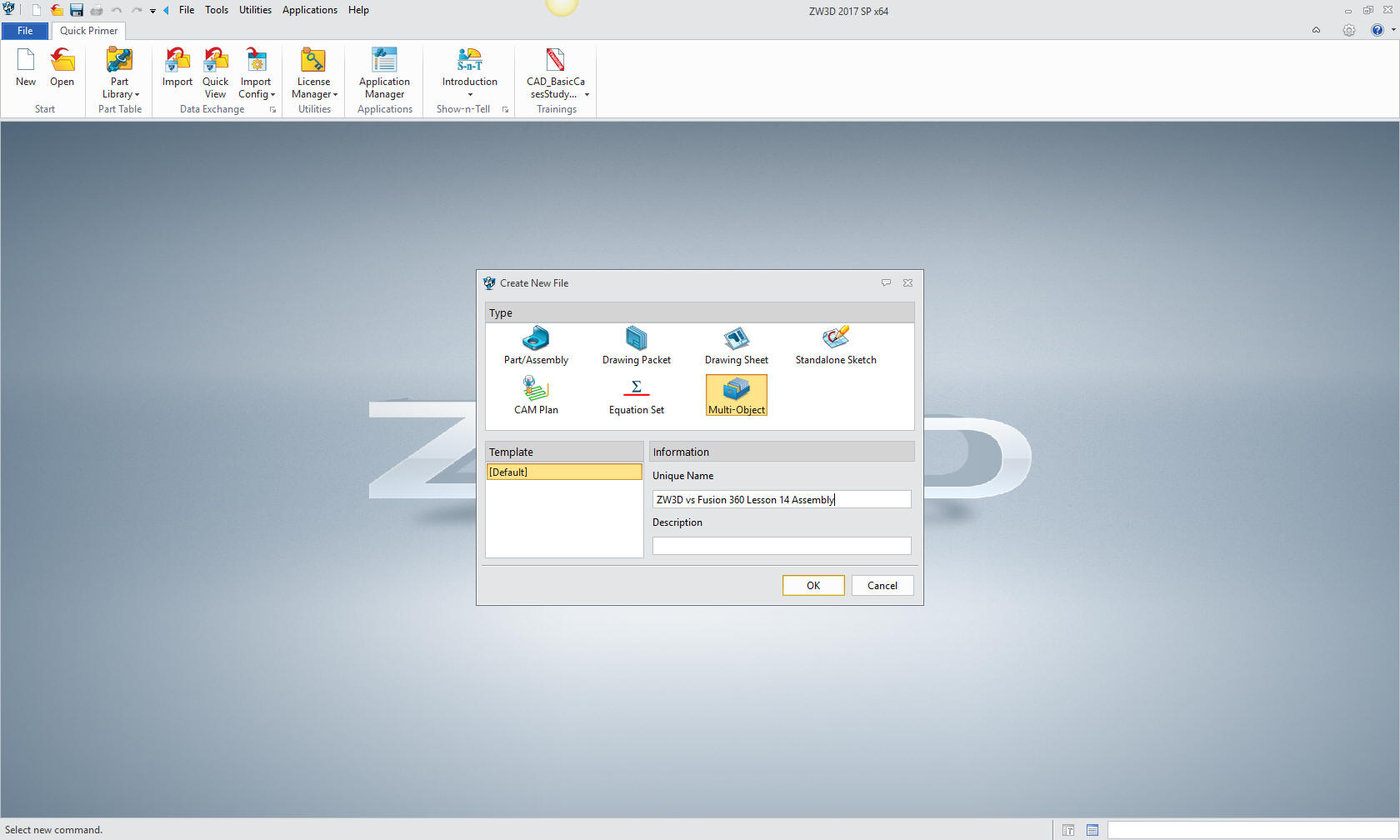

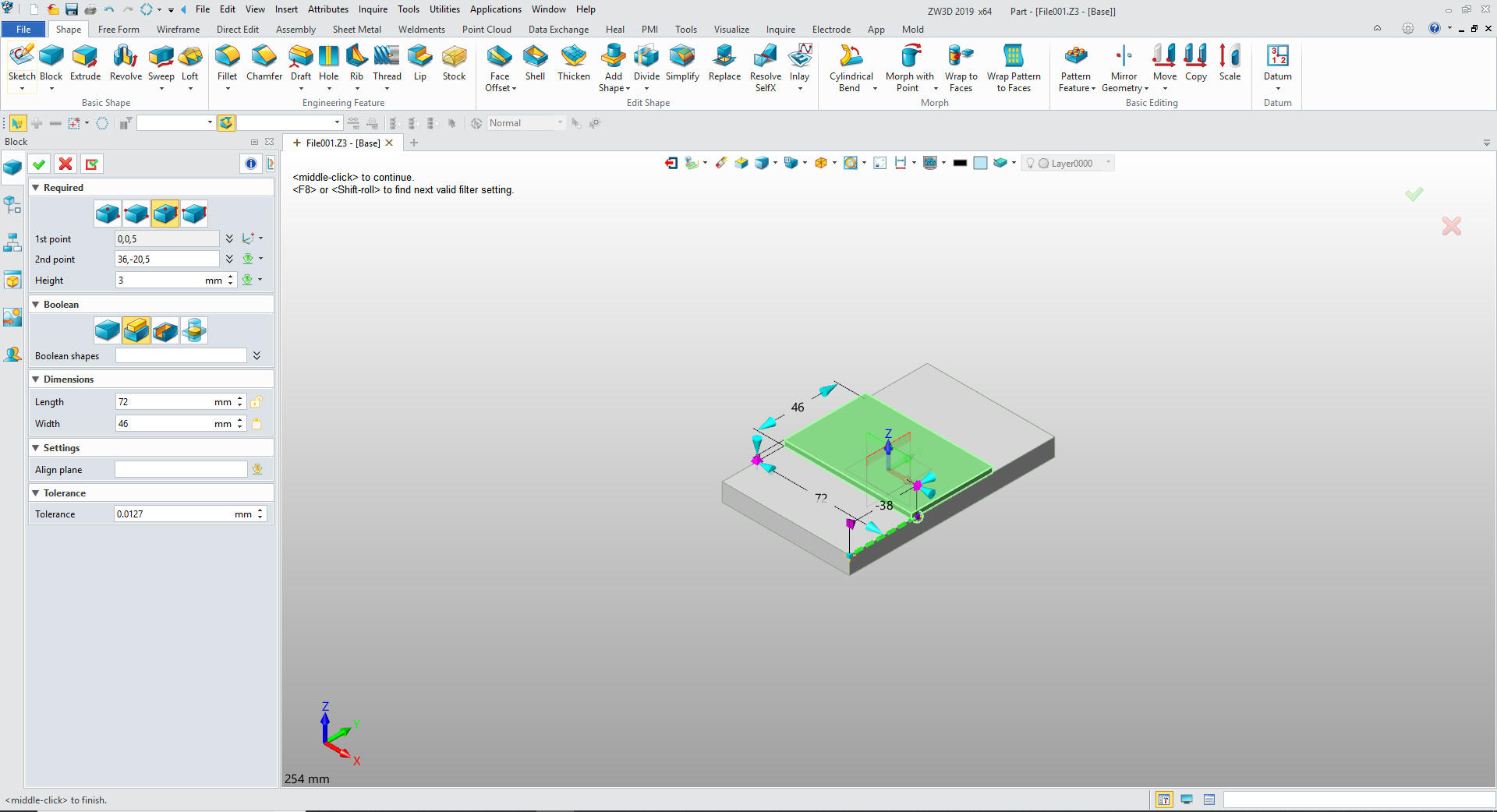

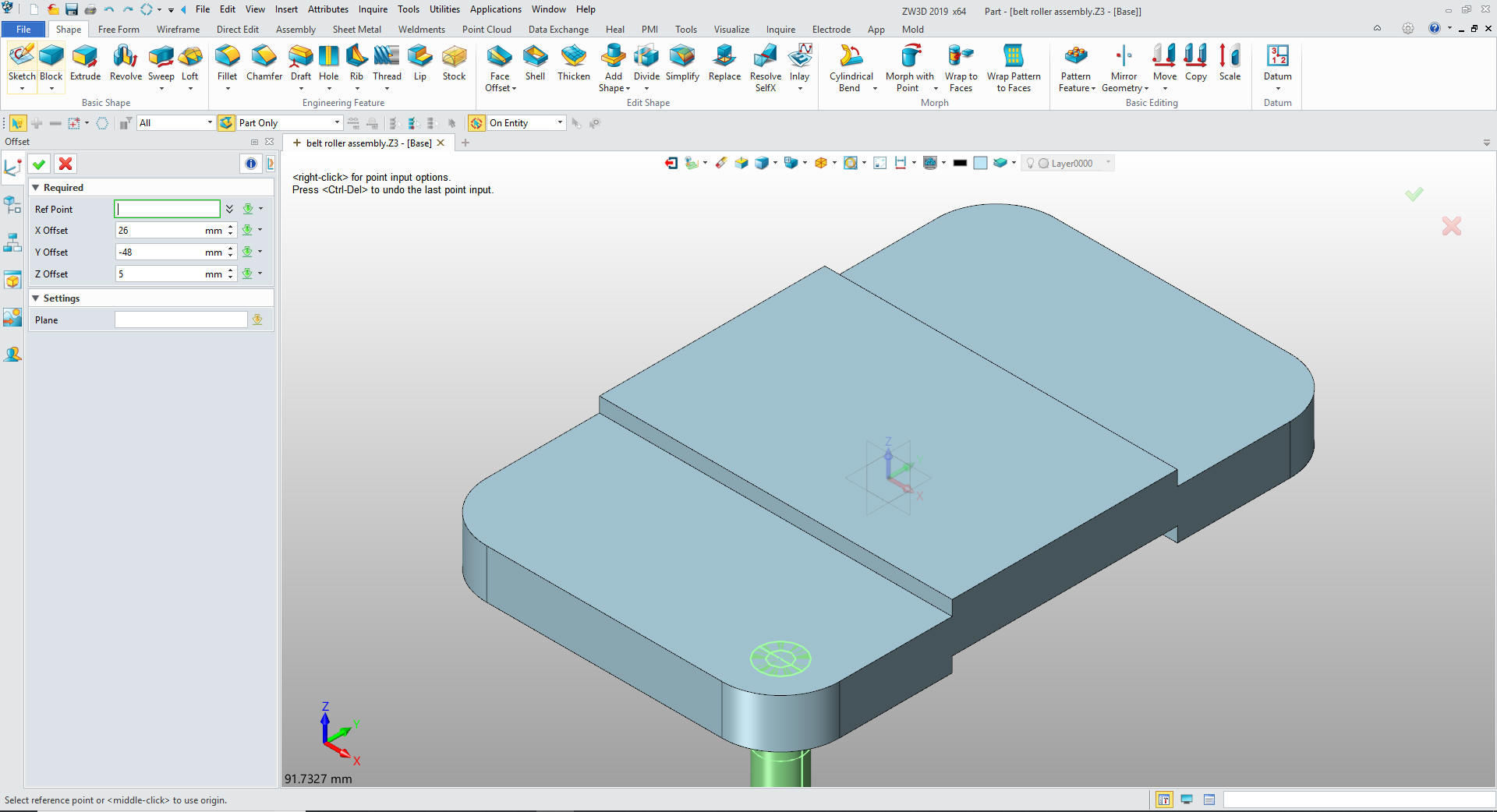

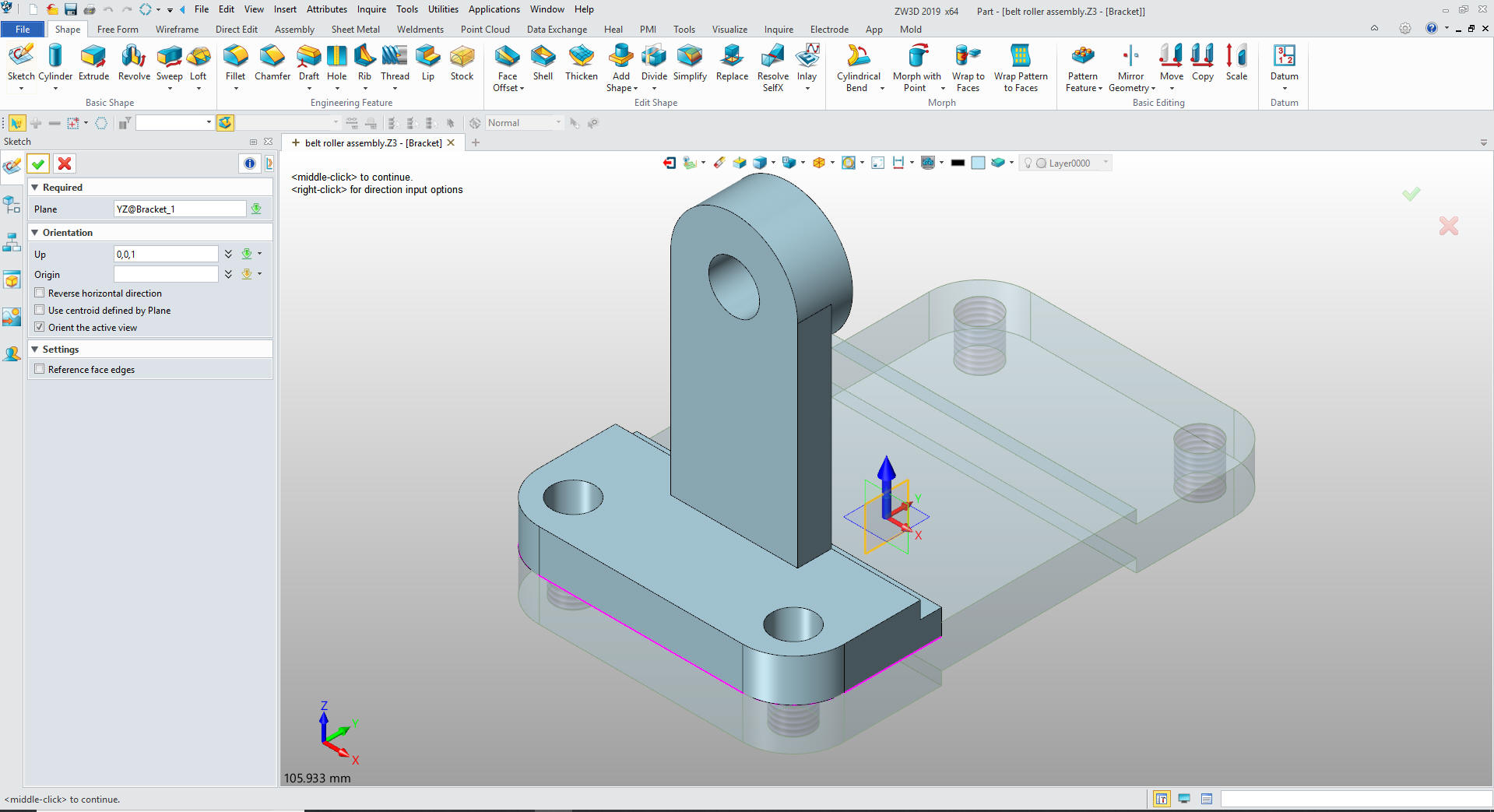

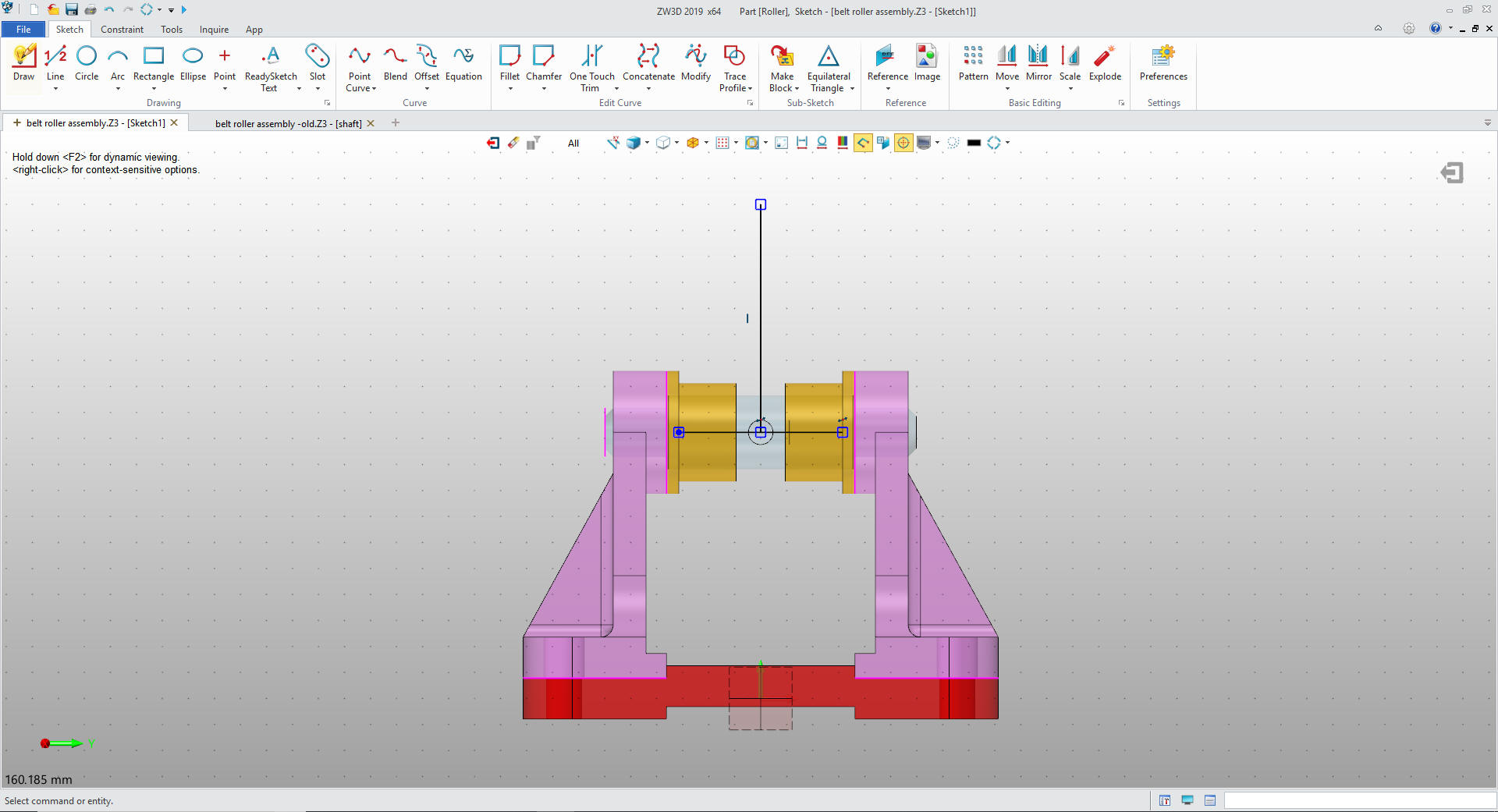

Here is ZW3D. It is set to mm so let's

get started

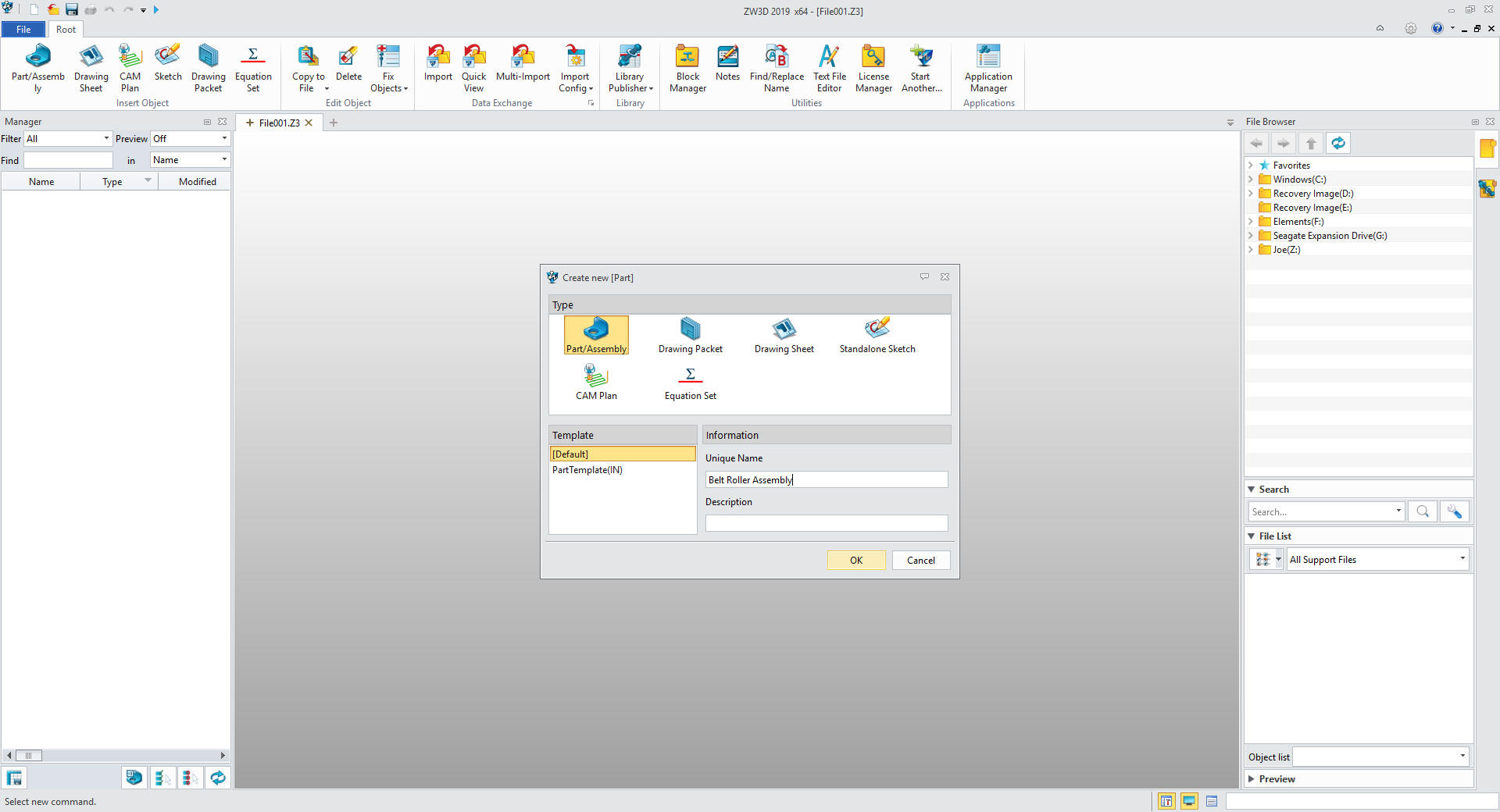

Like Solid Edge we have to set ZW3D for an

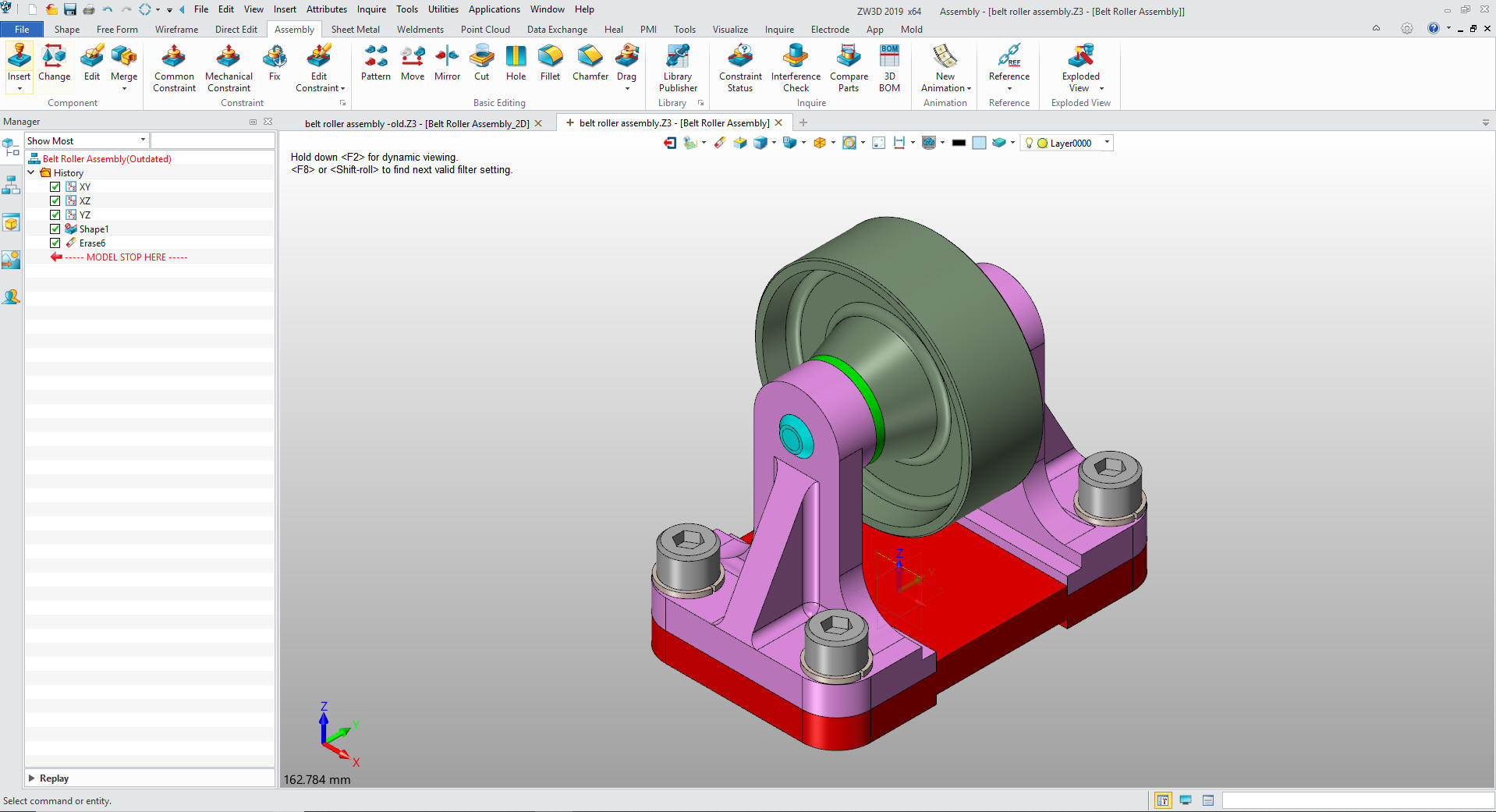

assembly. We open a multi-object file and call it Belt Roller

Assembly

These have actually turned into exercises in

modeling techniques as compared to showing a more productive CAD

systems. Again, I say there are many different ways to model a part.

I see with my exposure to direct edit modelers like CADKEY, I

rarely sketch like you see the Solid Edge fellow doing. I have always

created my basic sketches by mostly creating offsets and trimming or

extending. It seems to be much easier. I never put in a fillet that

can be created later. What do you think?

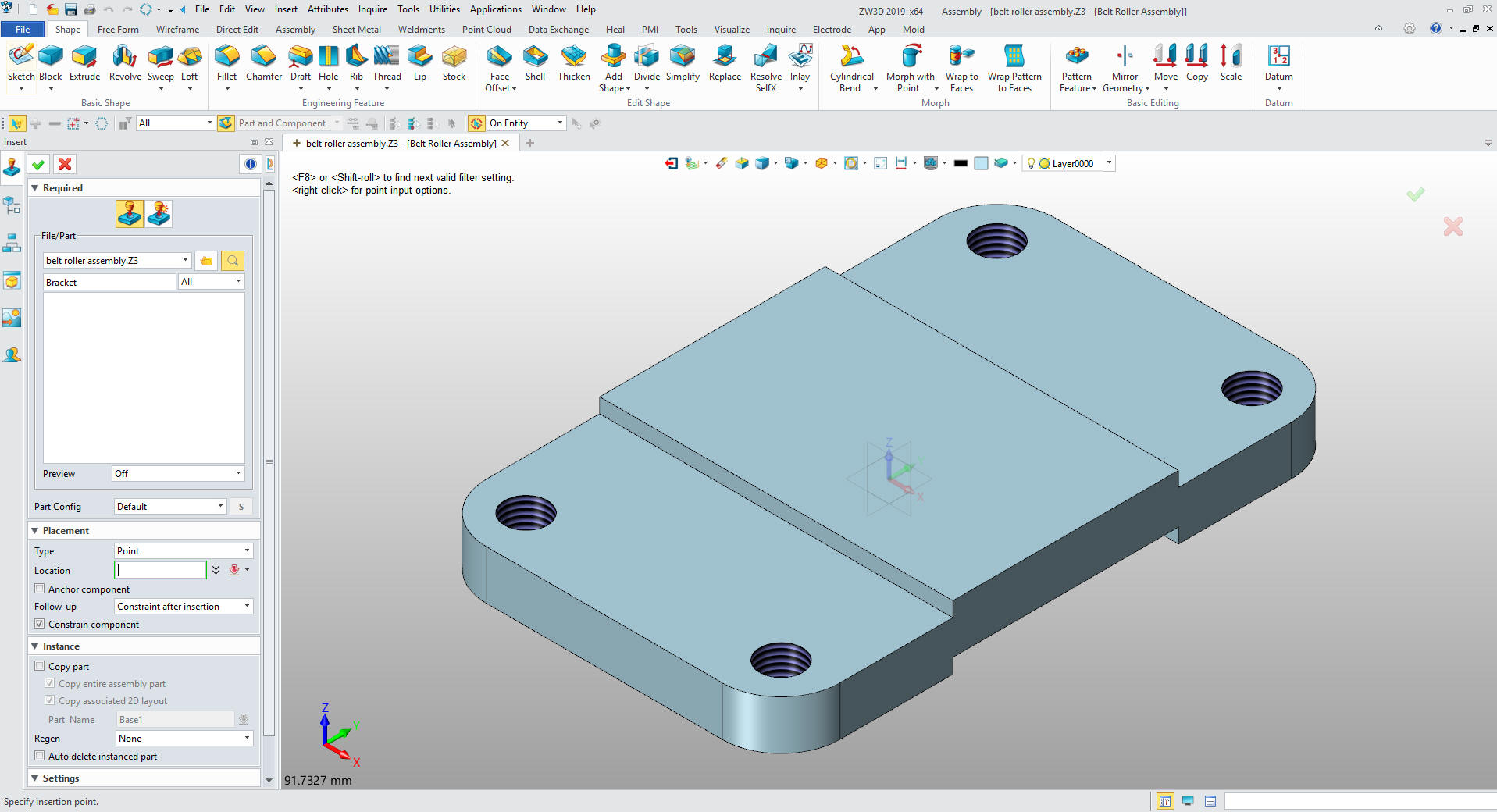

I will first create my part which will

be the top assembly and call it also the Belt Roller Assembly.

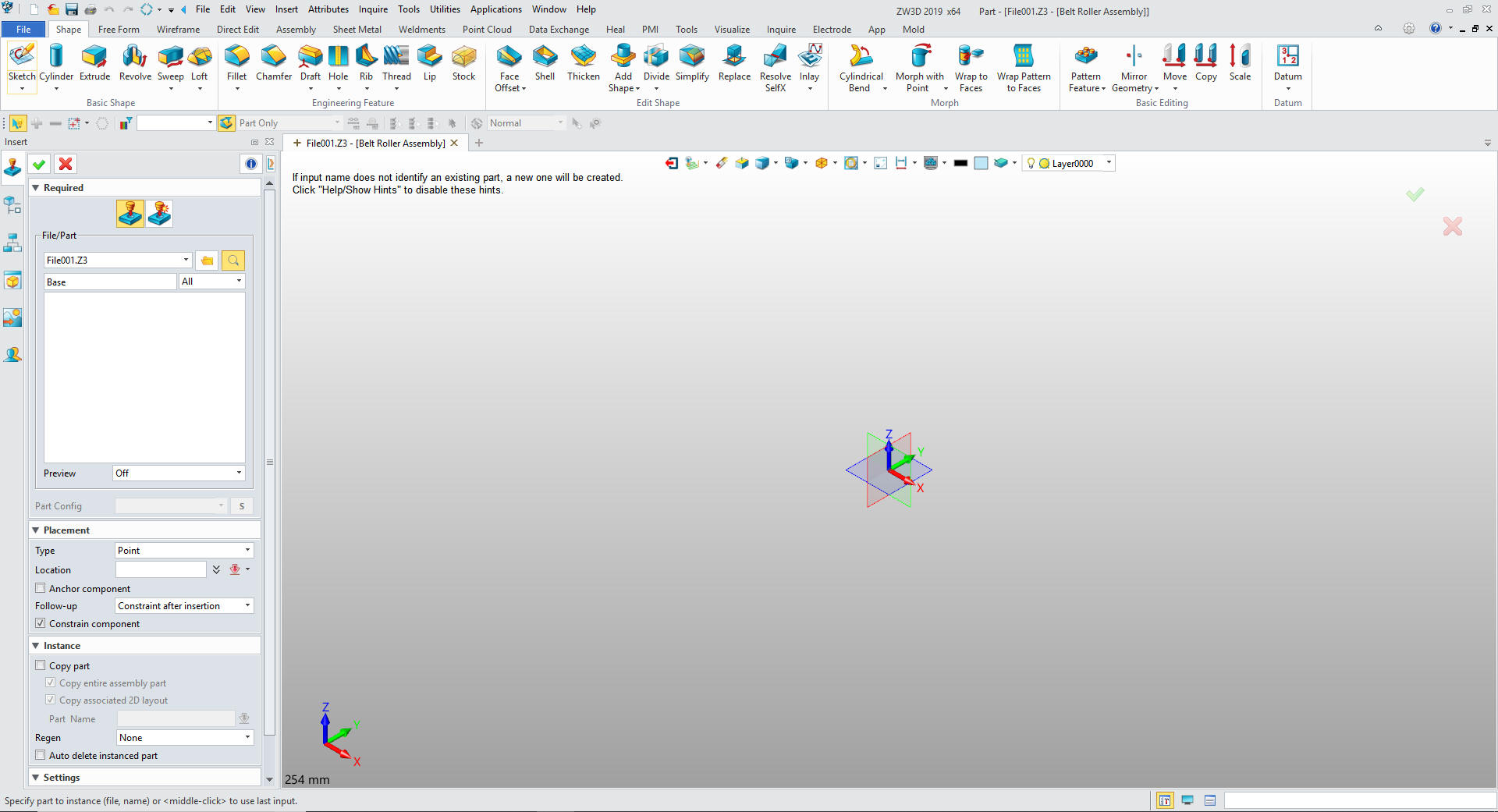

We

will now insert our first component the Base

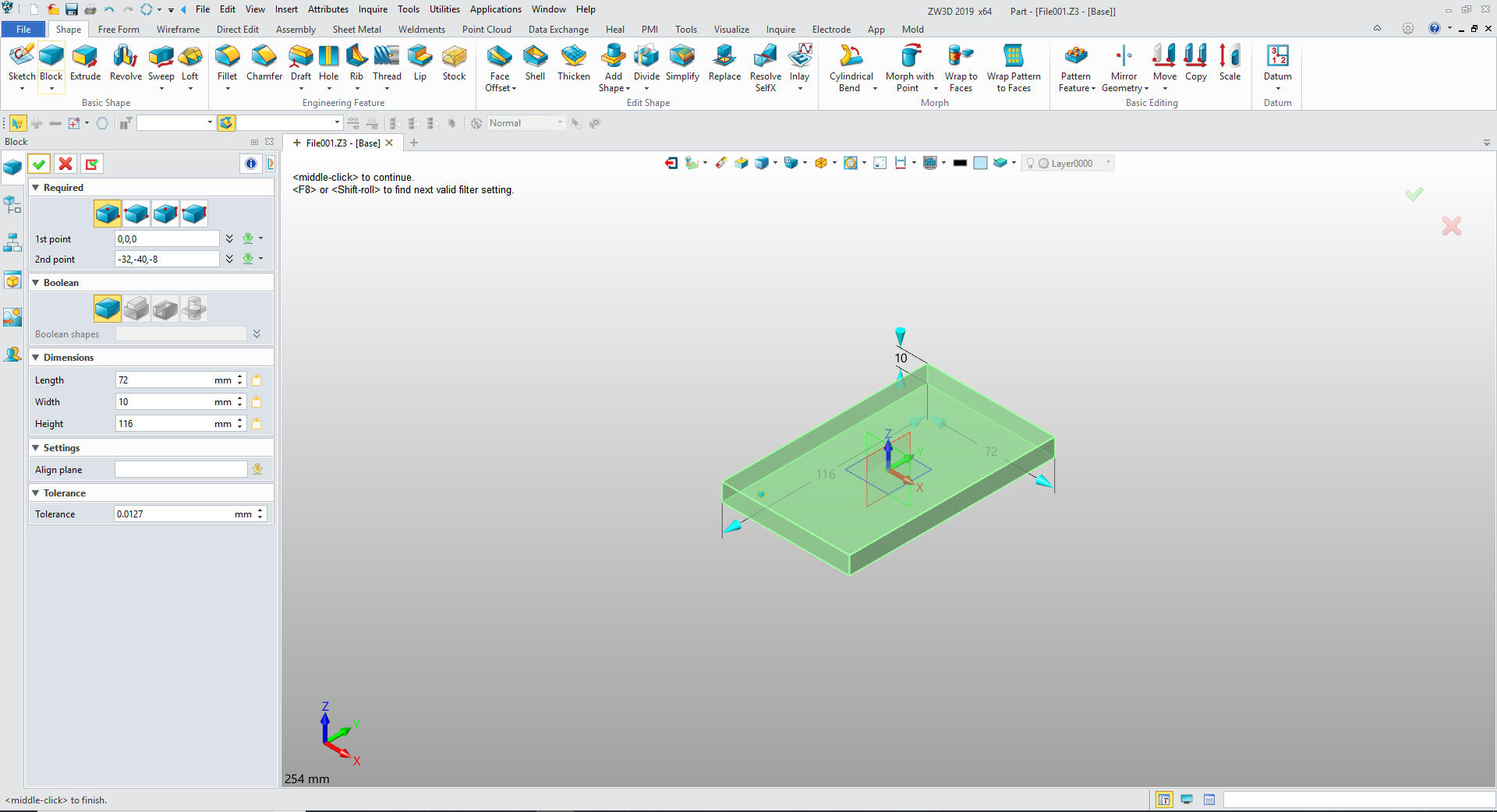

We will now

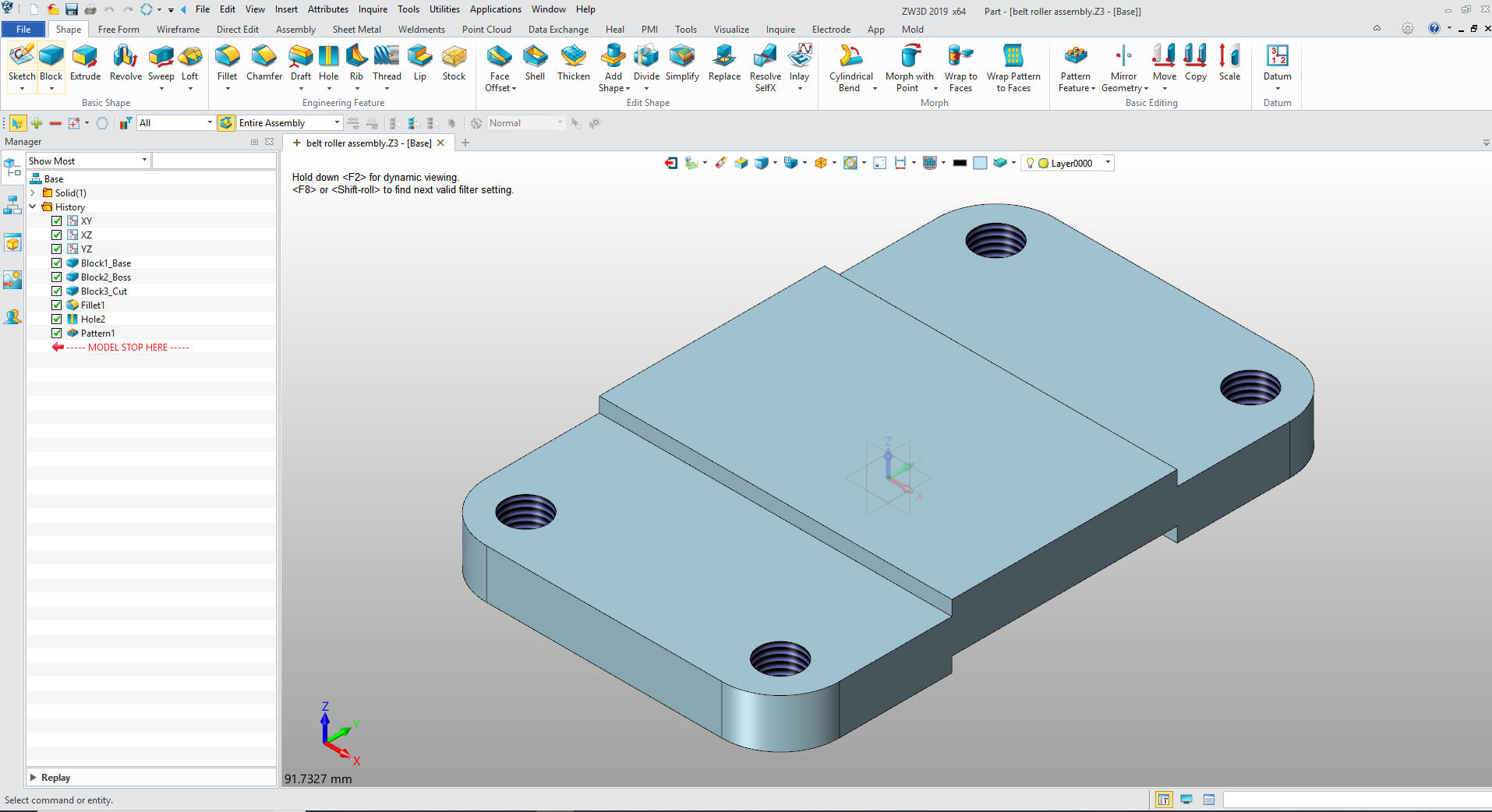

start our part by inserting a primitive block shape and sizing it.

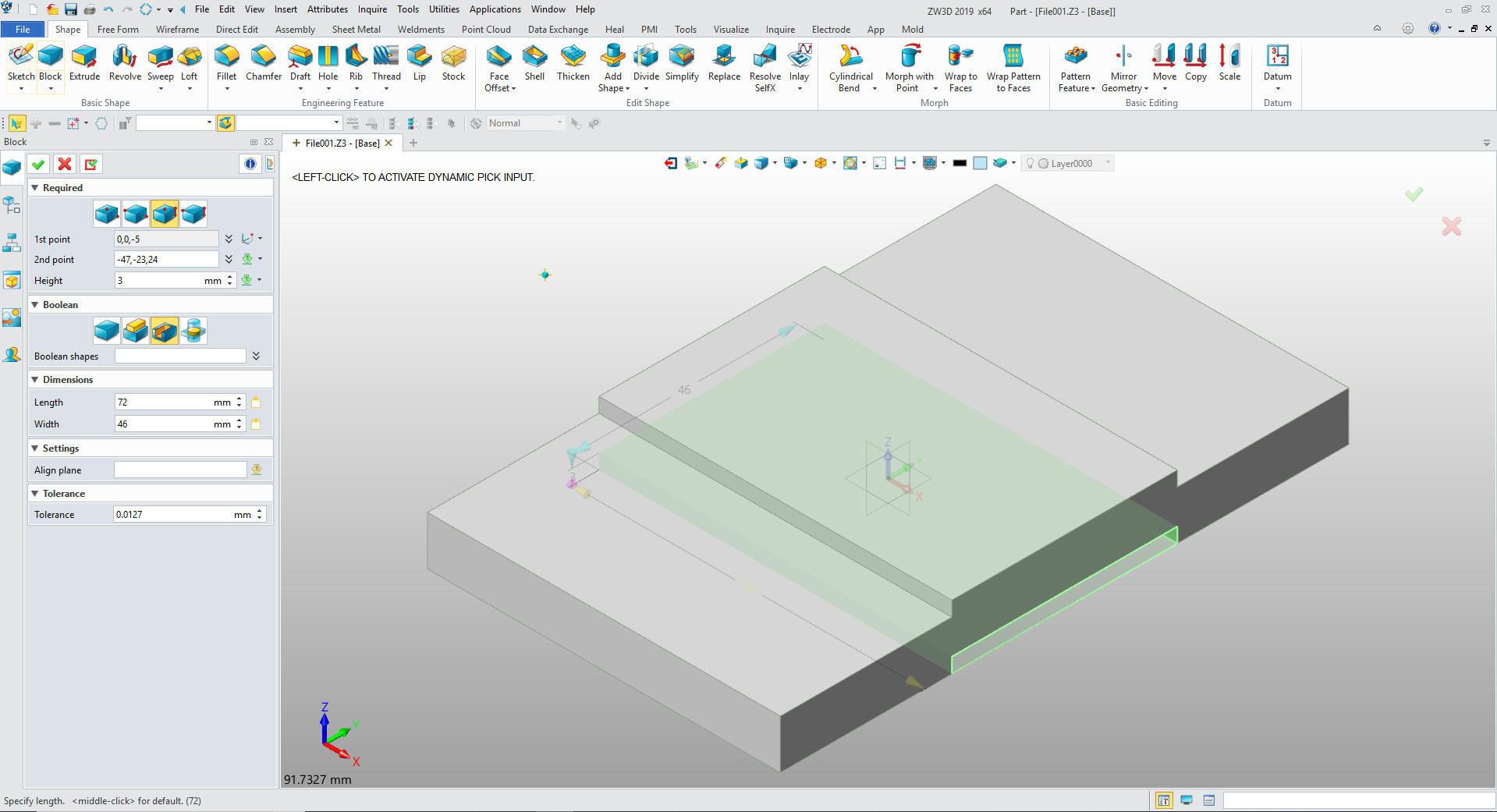

I will insert another primitive block,

size and locate it and set it to add.

Now insert

another primitive block, size and locate it and set it to remove

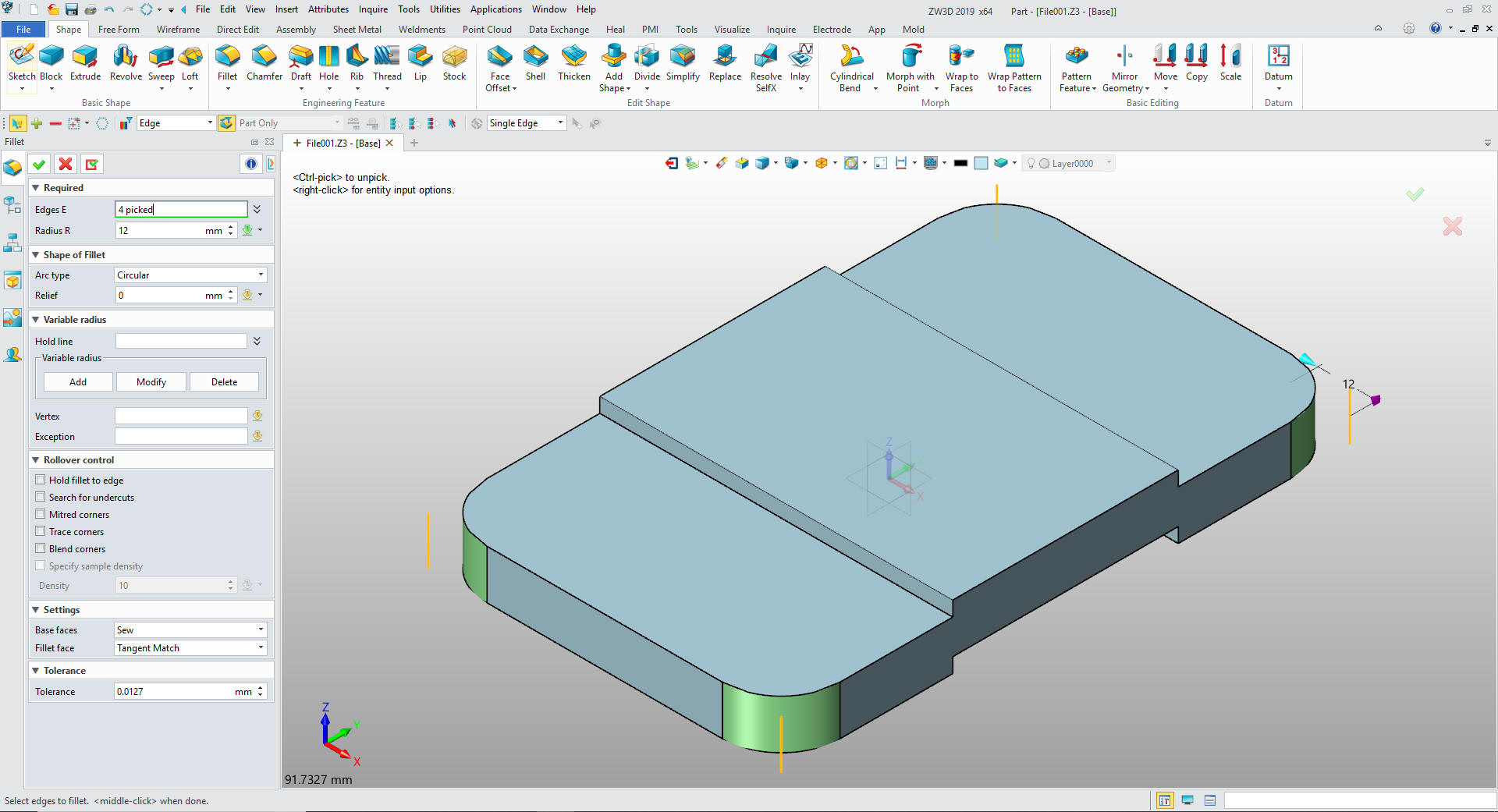

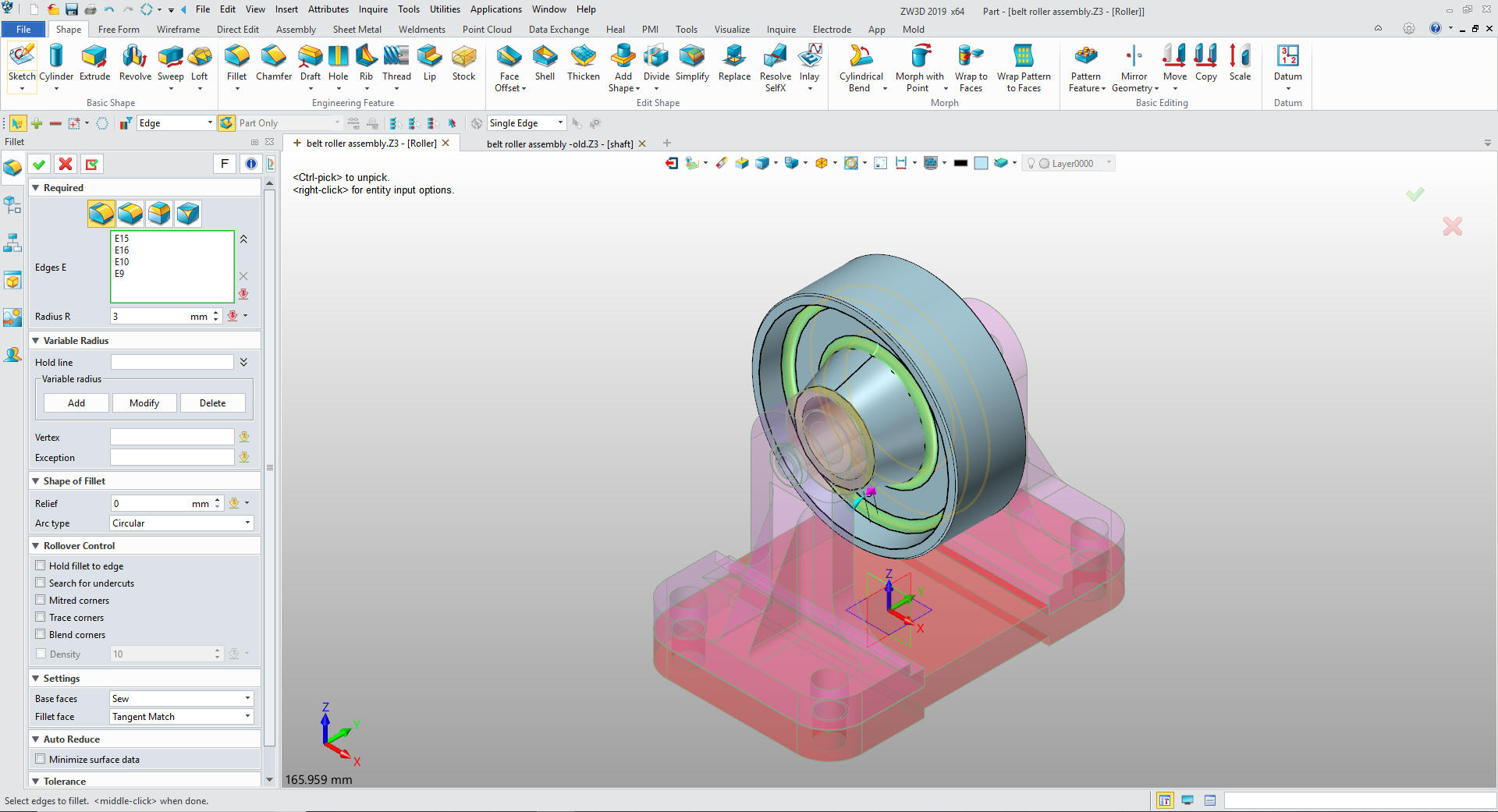

I put in the fillets.

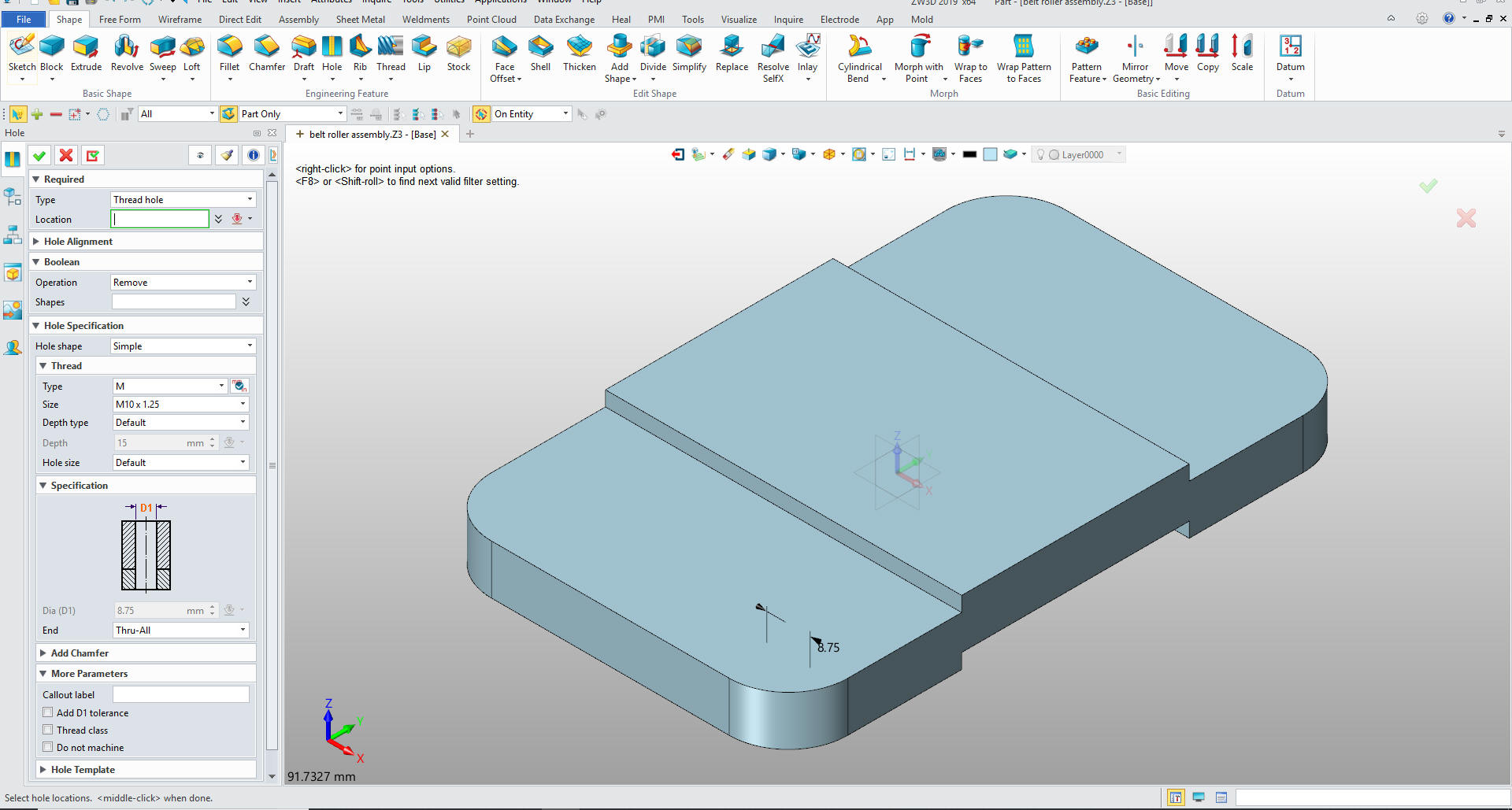

For the threaded hole we bring up the

Create Hole Feature. We set our hole specs.

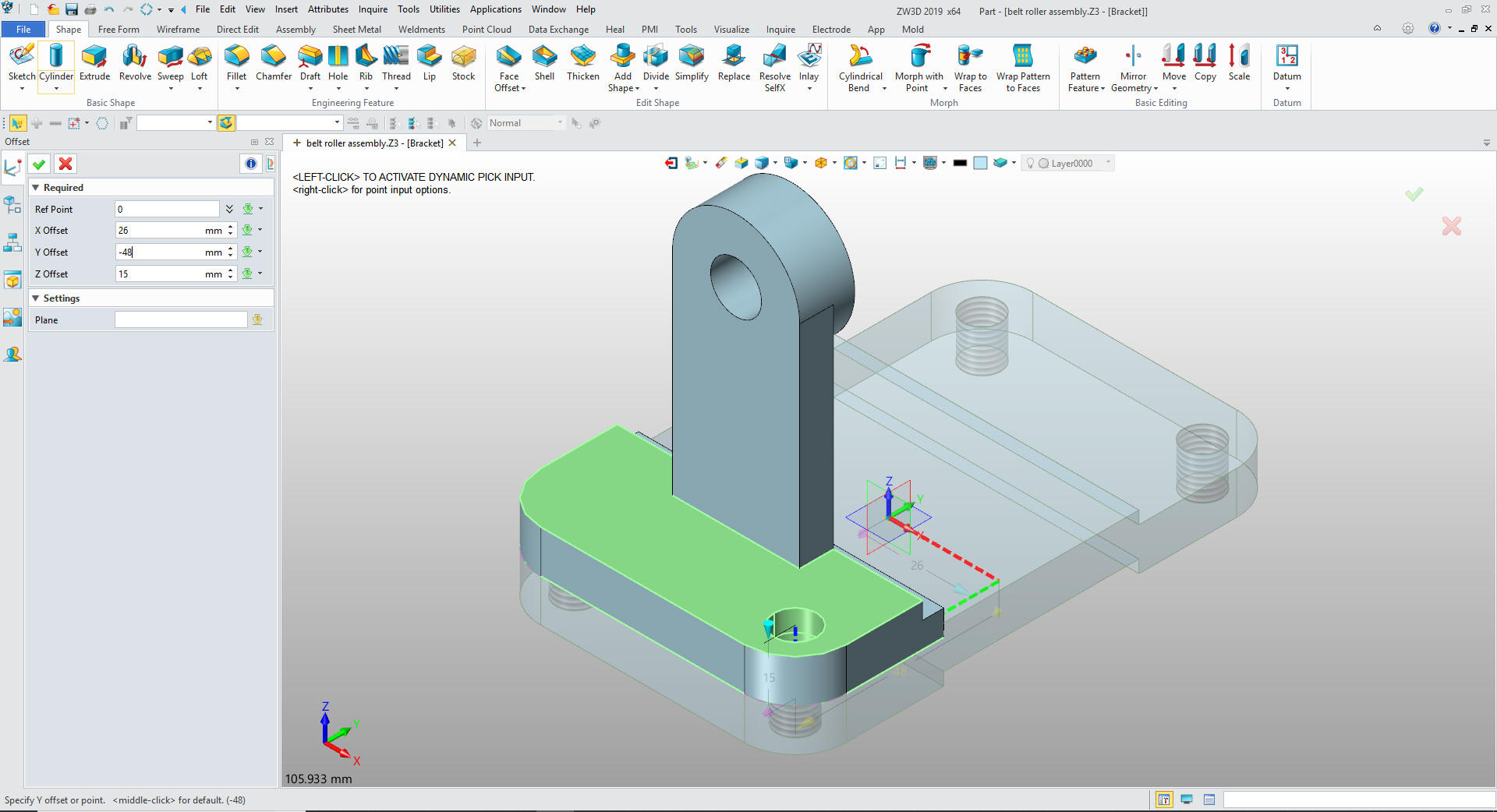

We locate the hole by selecting

offset from the options.

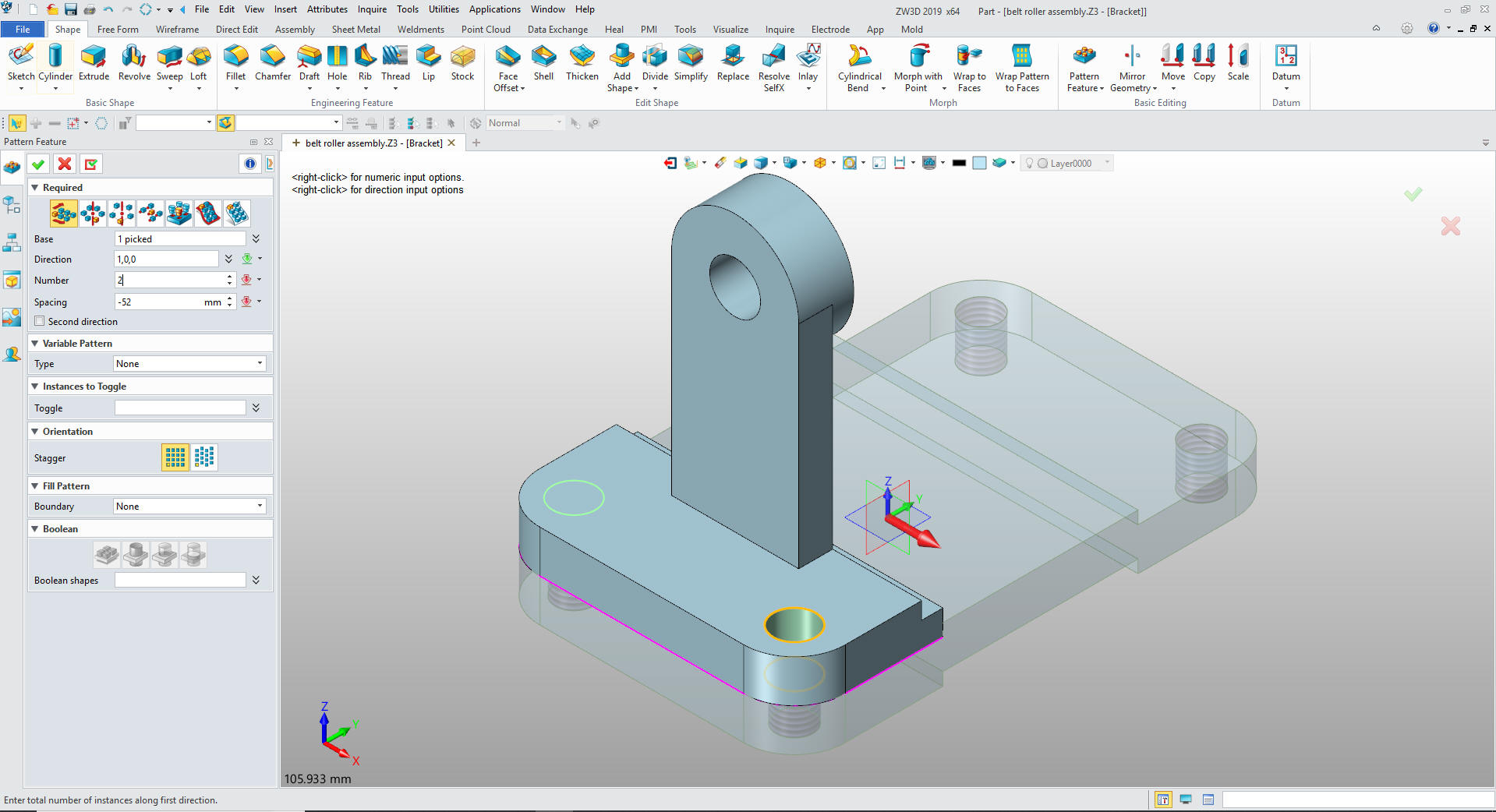

Using

the pattern feature we create the other 3 holes. I can't believe it

is as complicated to locate a hole in Solid Edge.

I select okay and we are done with the

Base.

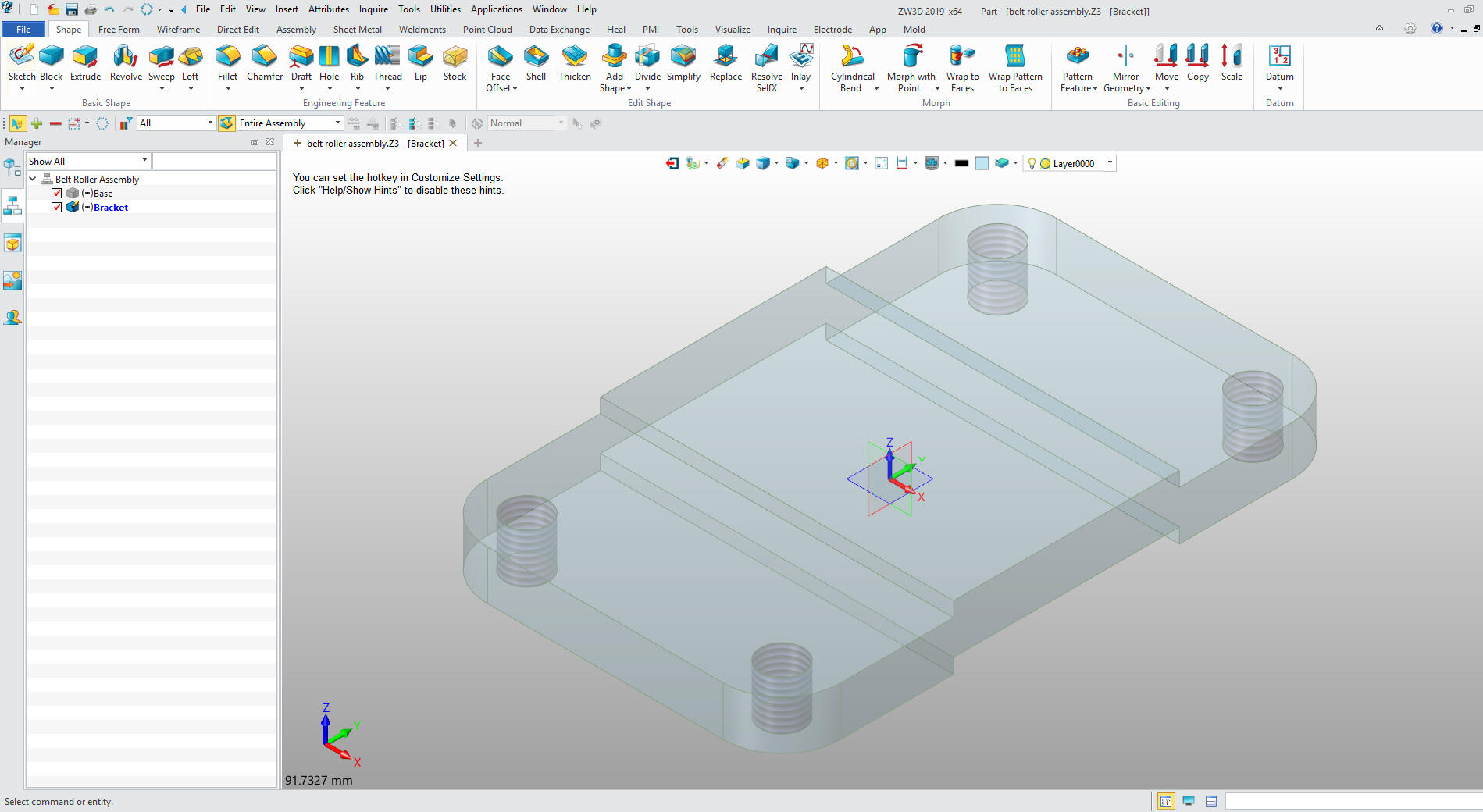

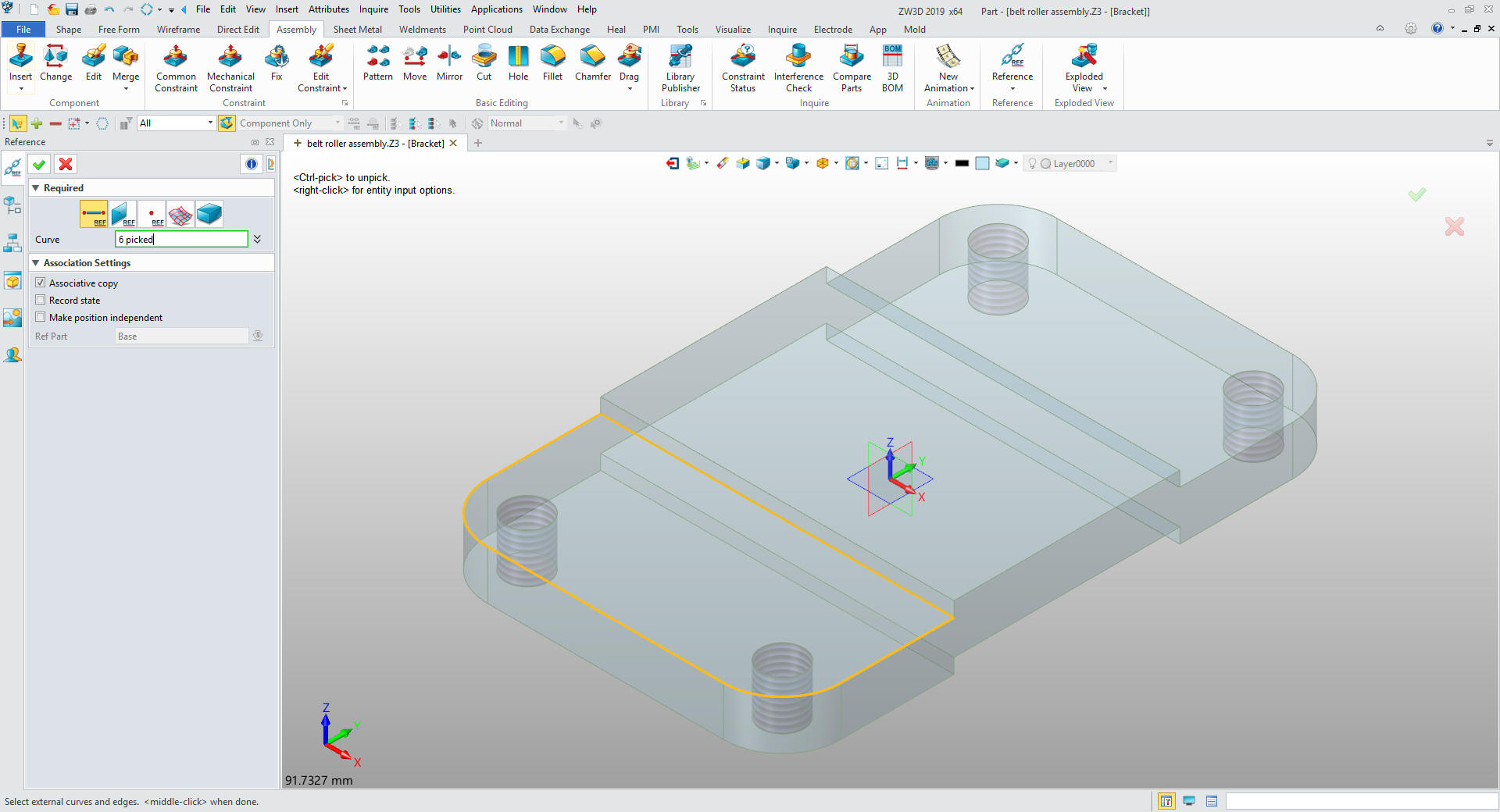

We now insert a new component called Bracket

As you can see the base is now a reference part that can be used for

in context design for the bracket.

The

bracket based will be created by creating reference graphics in the

assembly tool.

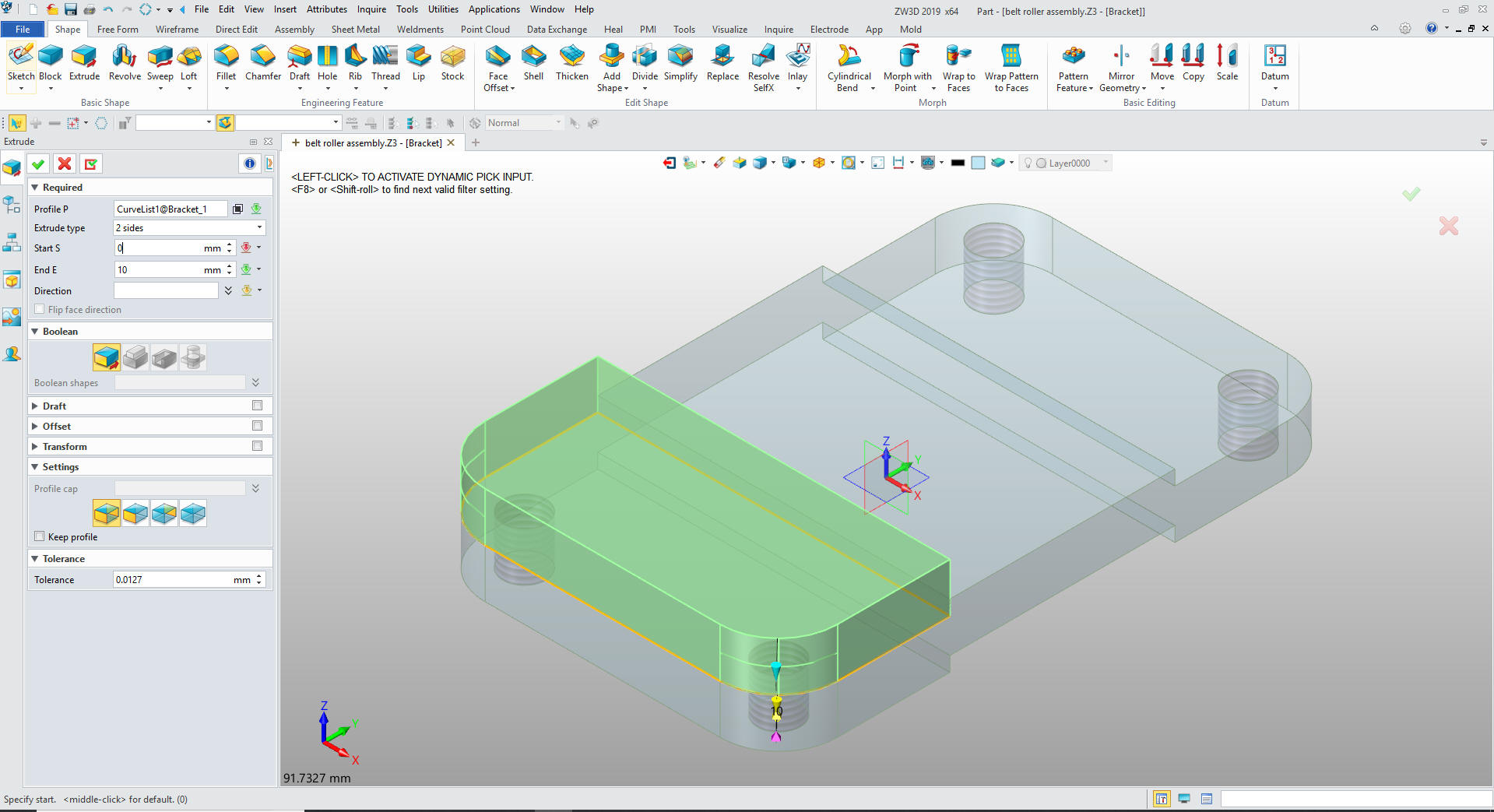

We

now turn these graphics into a curve list and extrude the shape.

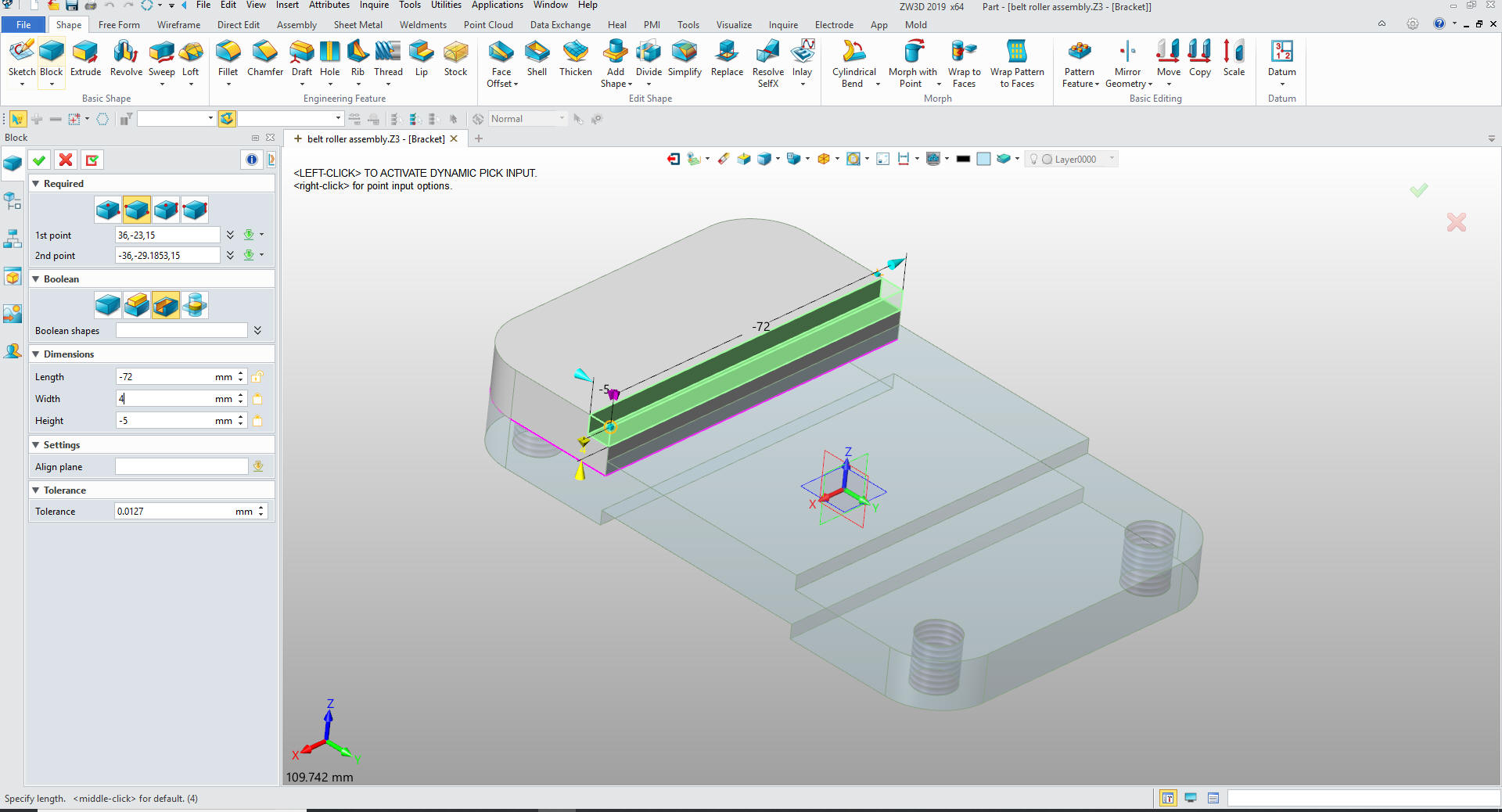

We add our cut by inserting a primitive

block locating and sizing it set it to remove.

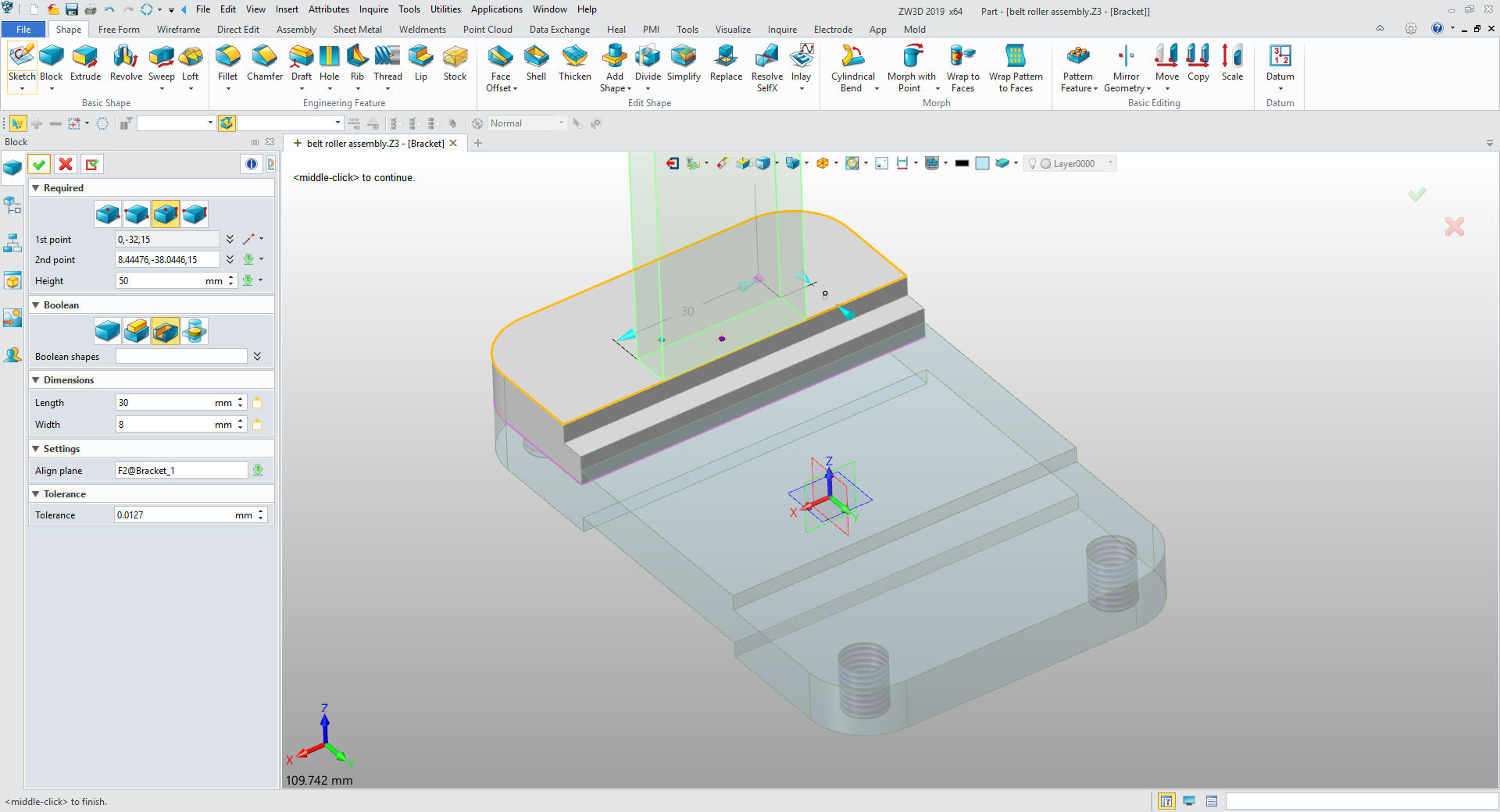

We insert another primitive block locate and size it and set to add.

Working with primitive shapes is fun. It is a short learning

curve but is so productive.

We

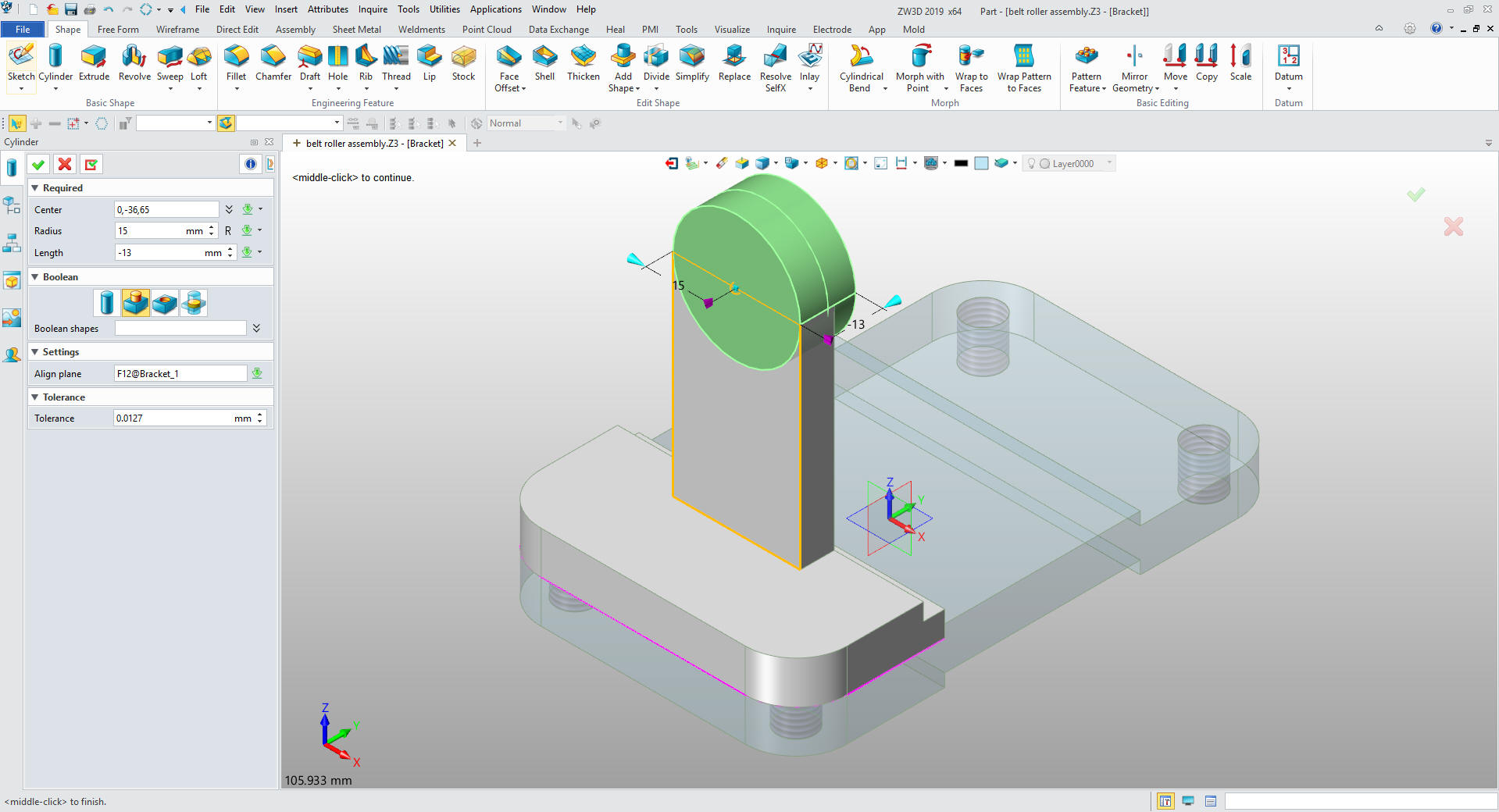

just insert a primitive cylinder locate and size it.

We

insert another primitive cylinder in the center of the boss, size it

and set to remove.

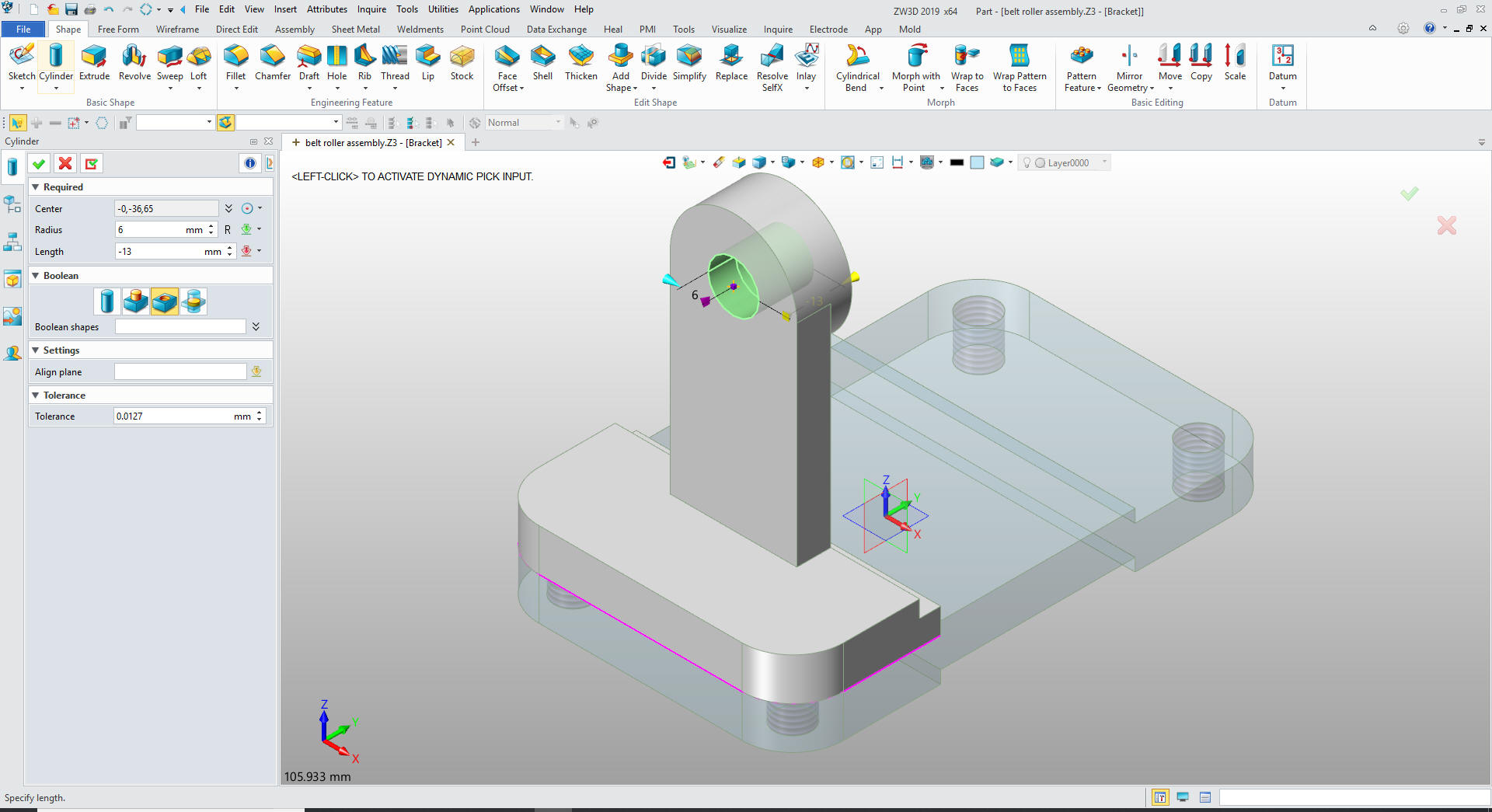

We

will insert a primitive cylinder, locate it and set to remove.

We pattern the hole.

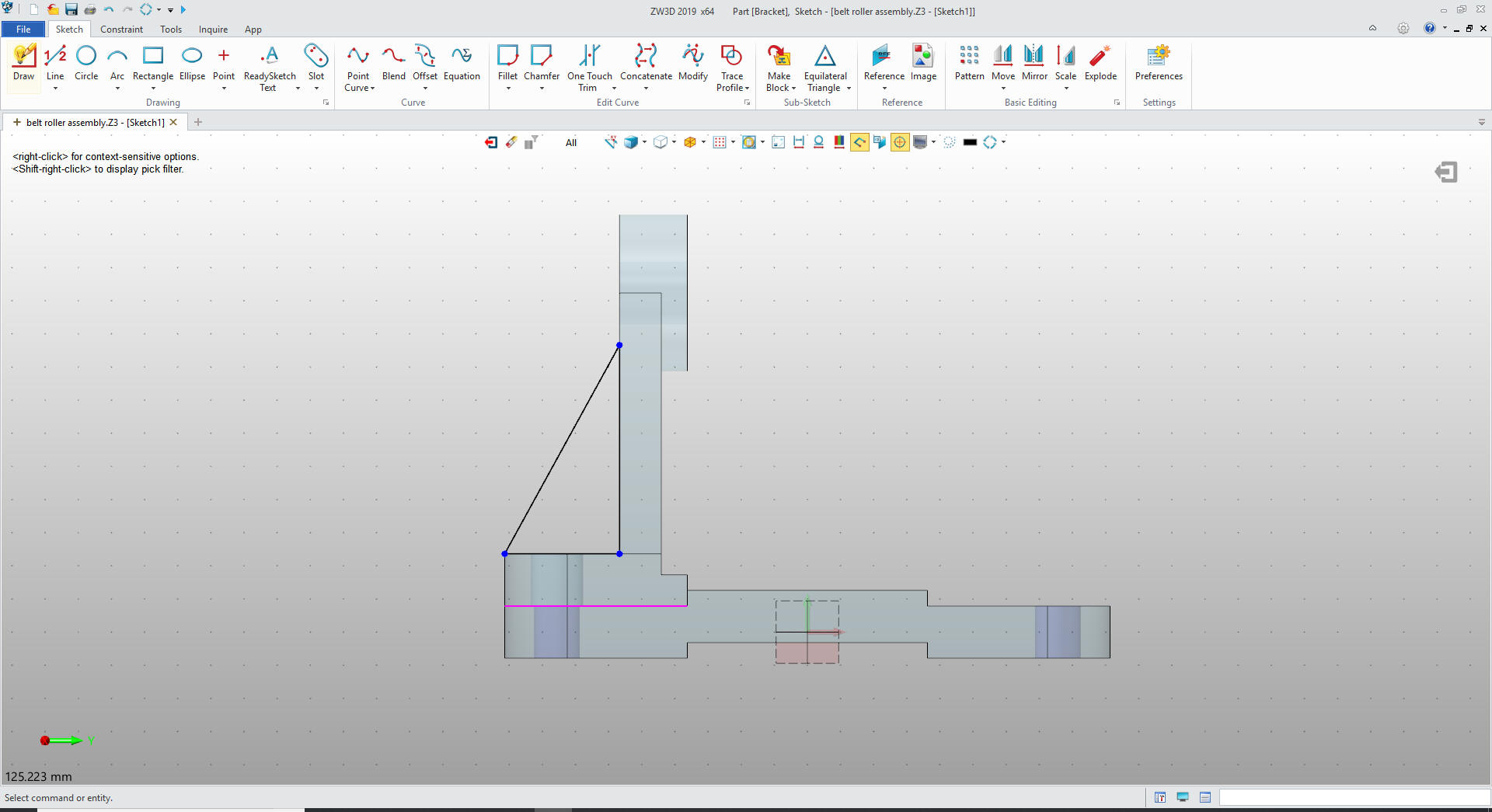

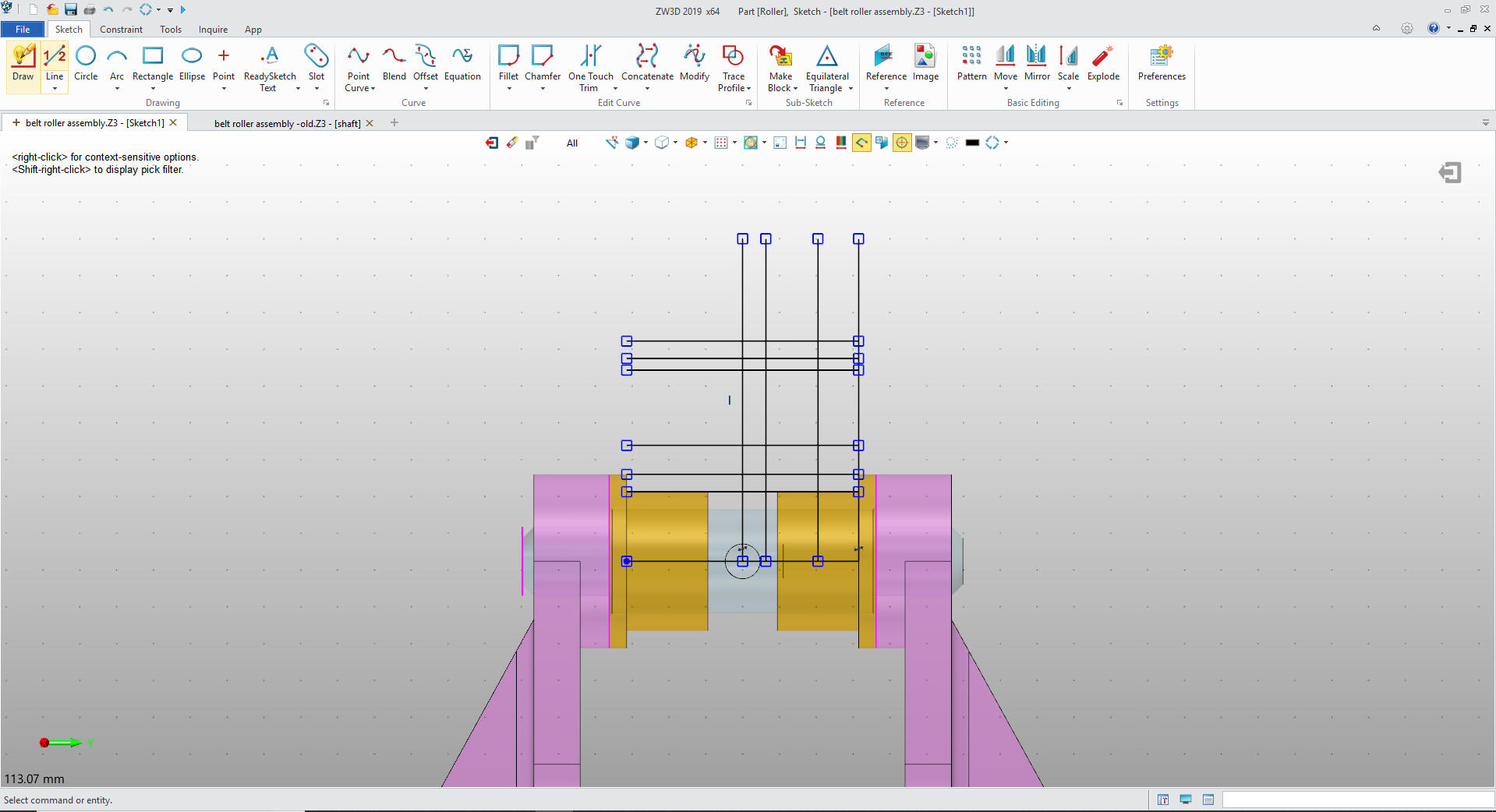

Now

for the rib we create a sketch. Yes, we do have to do some

sketching.

We

just use existing geometry to create the 3 lines. No constraints.

The only line we defined was the vertical that was set to 40 as we

put it in. The horizontal line was point to point.

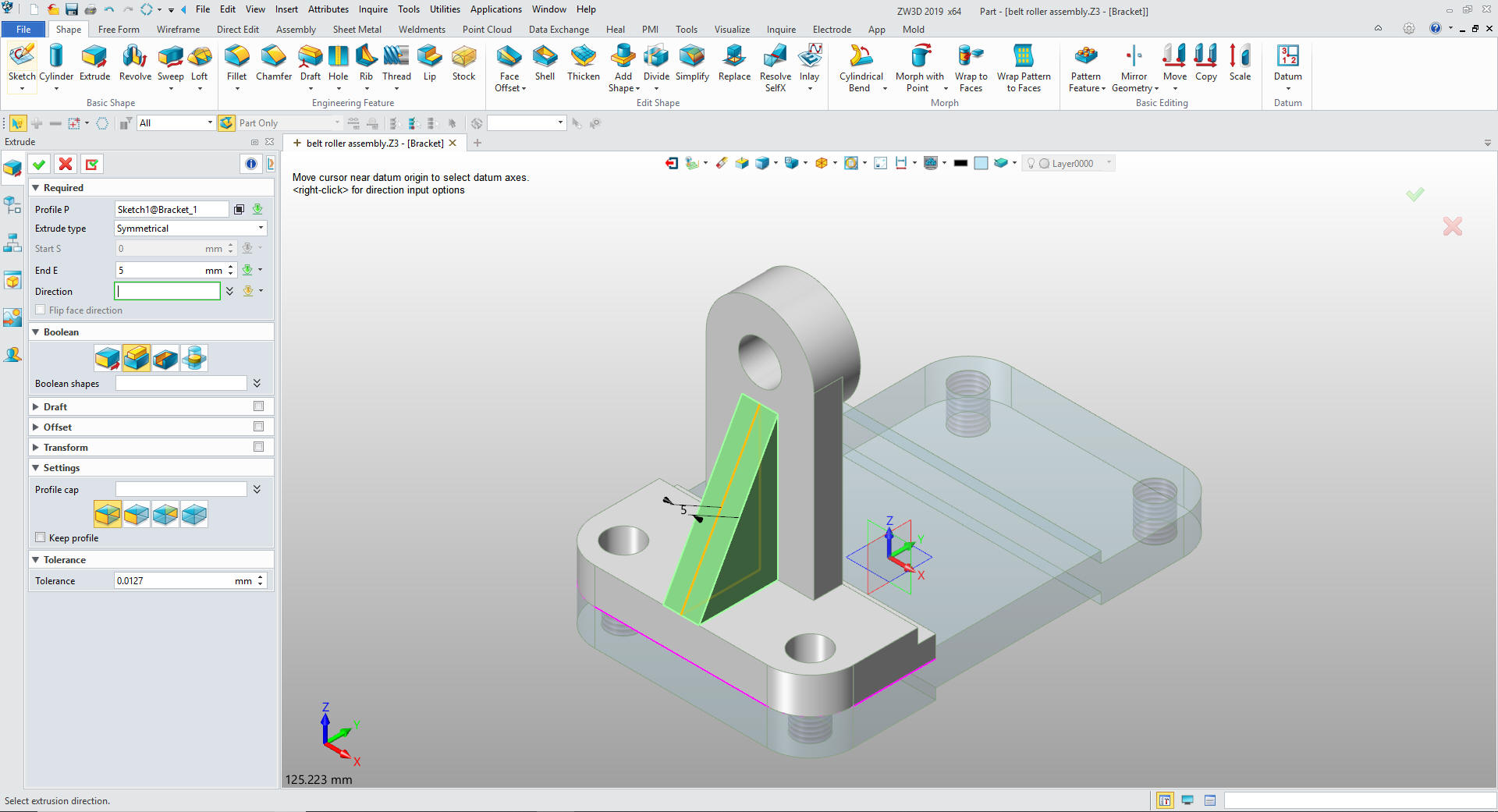

We

exit the sketch and select extrude, select symmetrical and size and

set to add.

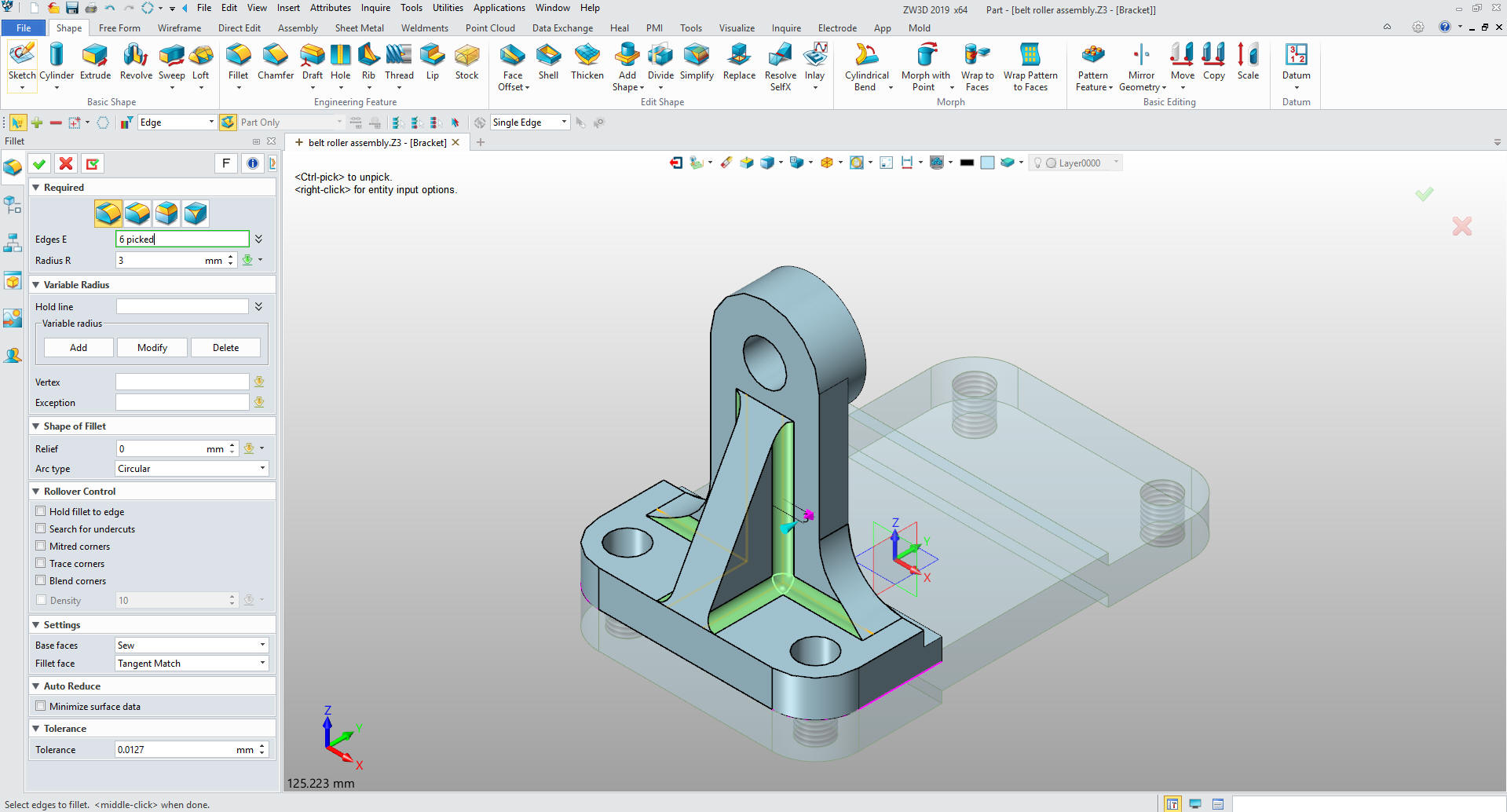

We

put in the blends and we are done.

We

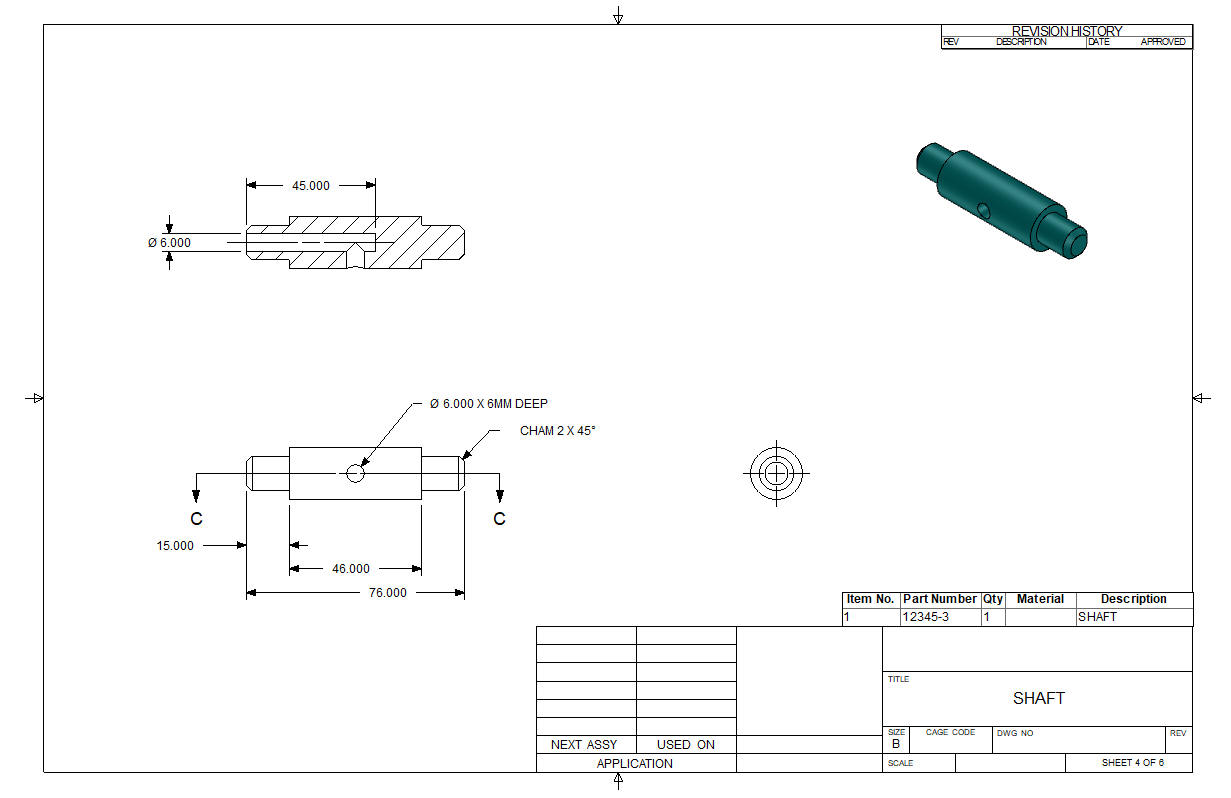

copy another bracket and locate it. We are ready for the shaft.

I create a reference circle and move it to the location to start

the part.

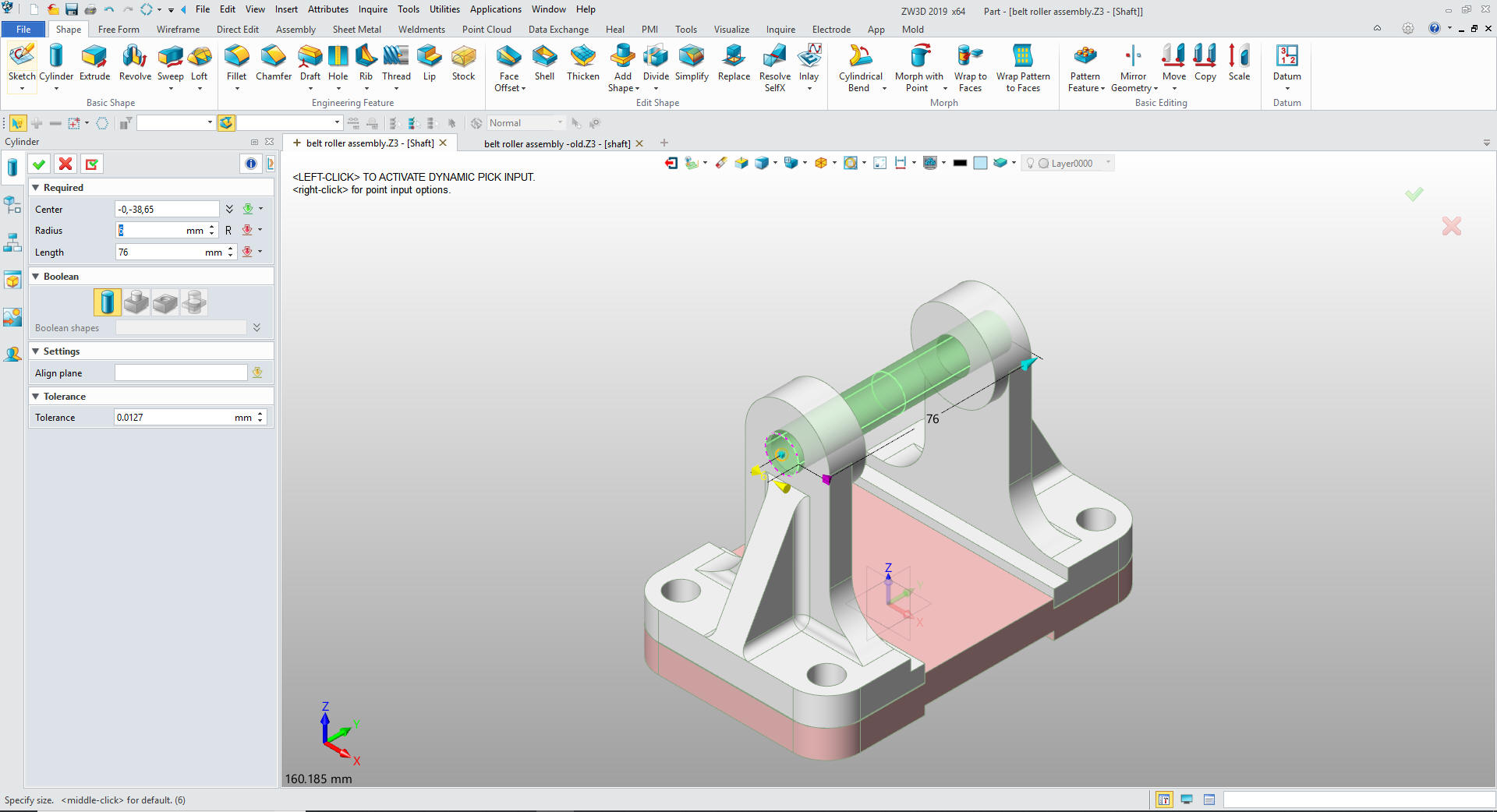

We insert a primitive cylinder using the reverence

circle and a set the diameter and length.

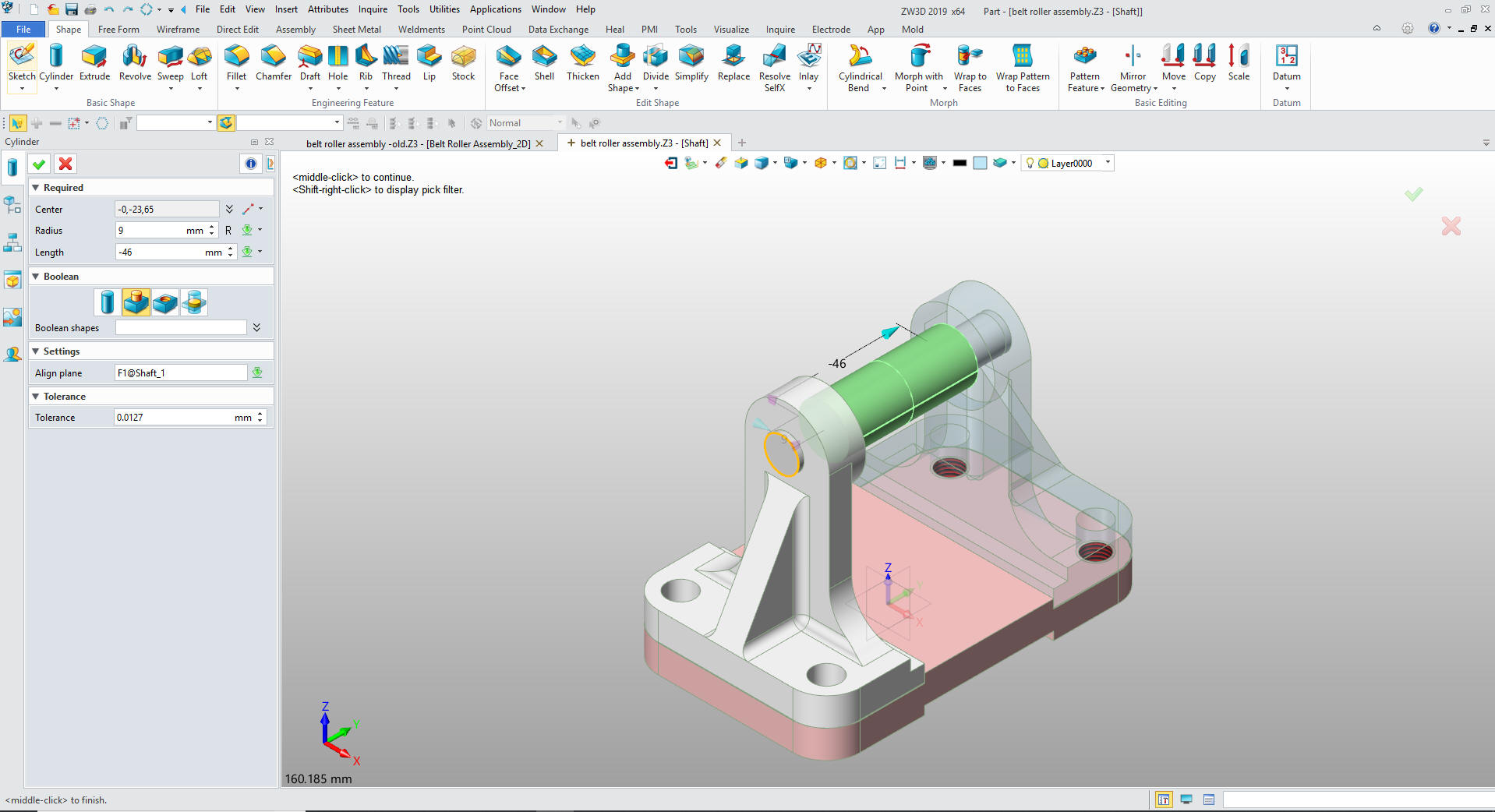

We

insert another primitive cylinder, locate set the diameter and

length.

We

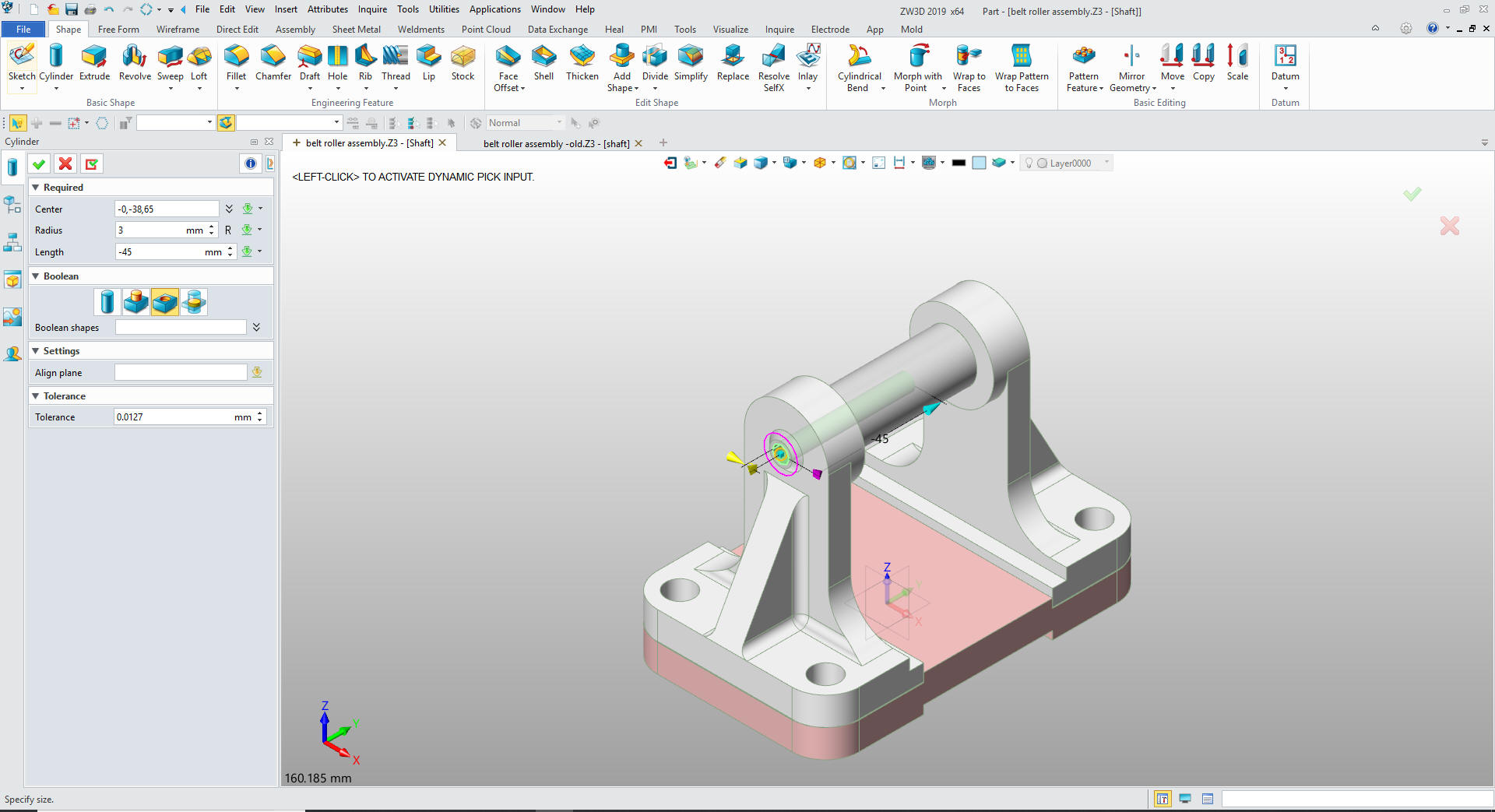

add the chamfers and create the hole by inserting a primitive

cylinder and setting the diameter and depth.

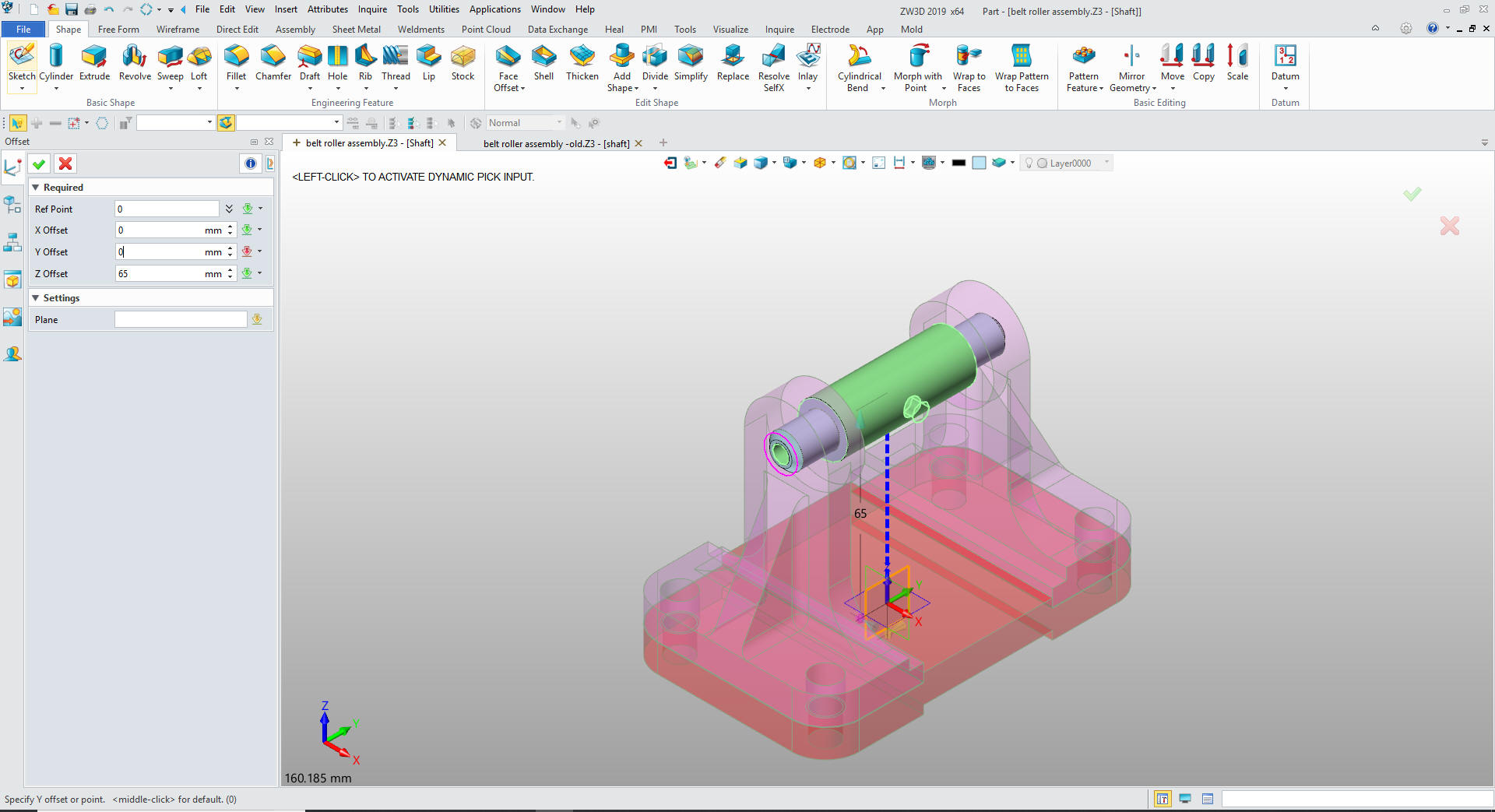

Now

for the side hole by inserting a primitive cylinder at X0Y0Z0 and

sizing and locating it. We are done with the part.

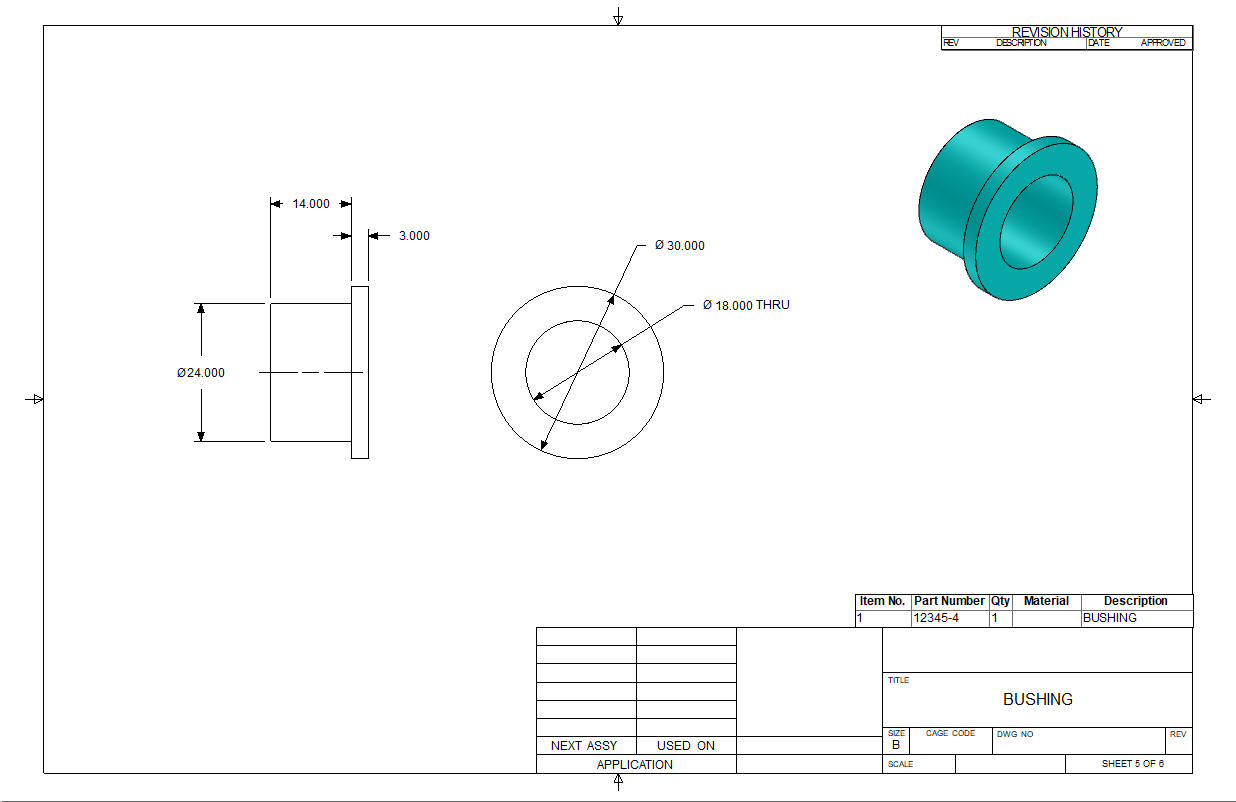

We

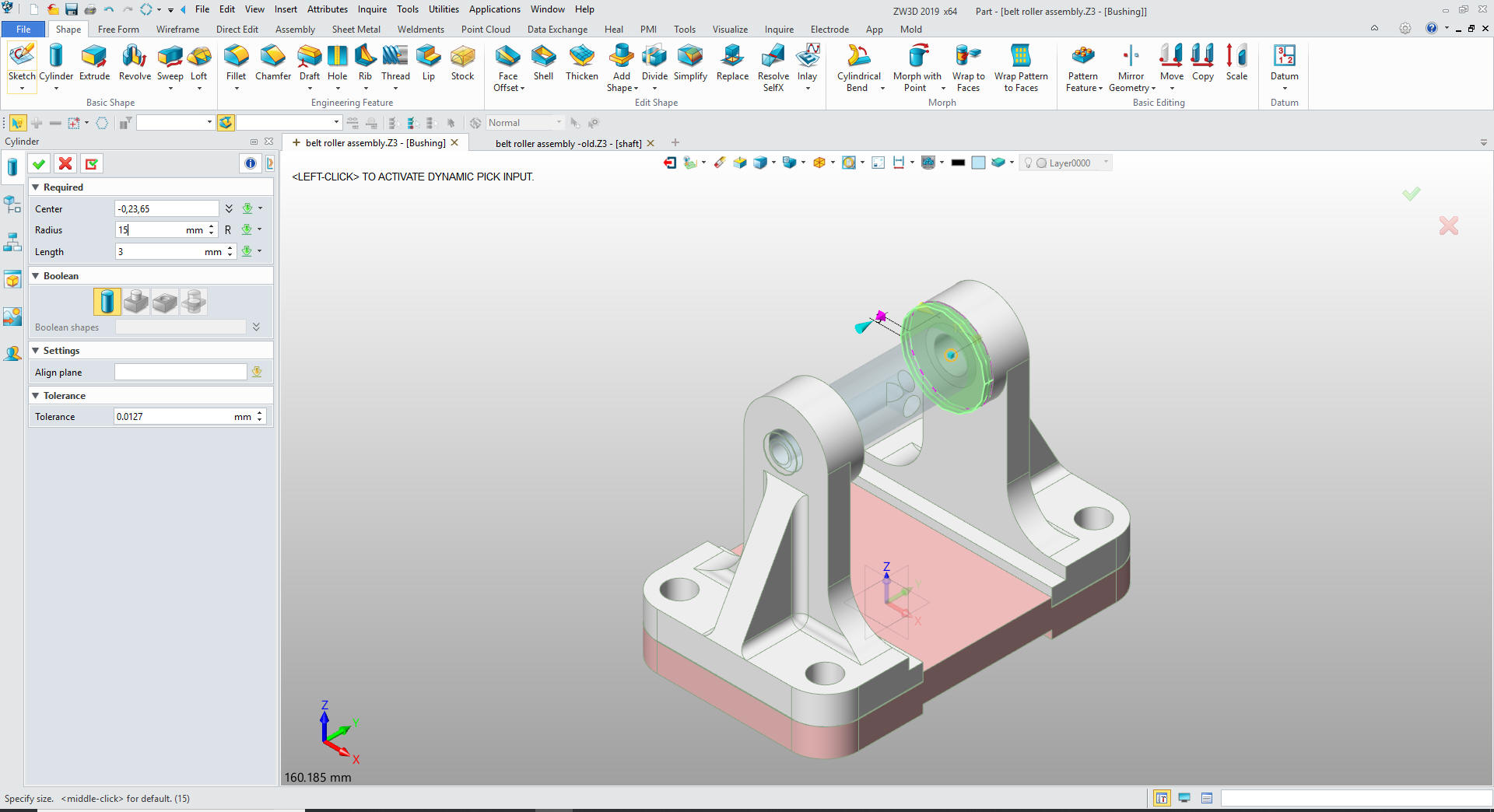

insert a new component and call it bushing, we create a reference

curve from the aft bracket boss and use

it for a reference to insert a cylinder, we set the diameter and

thickness,

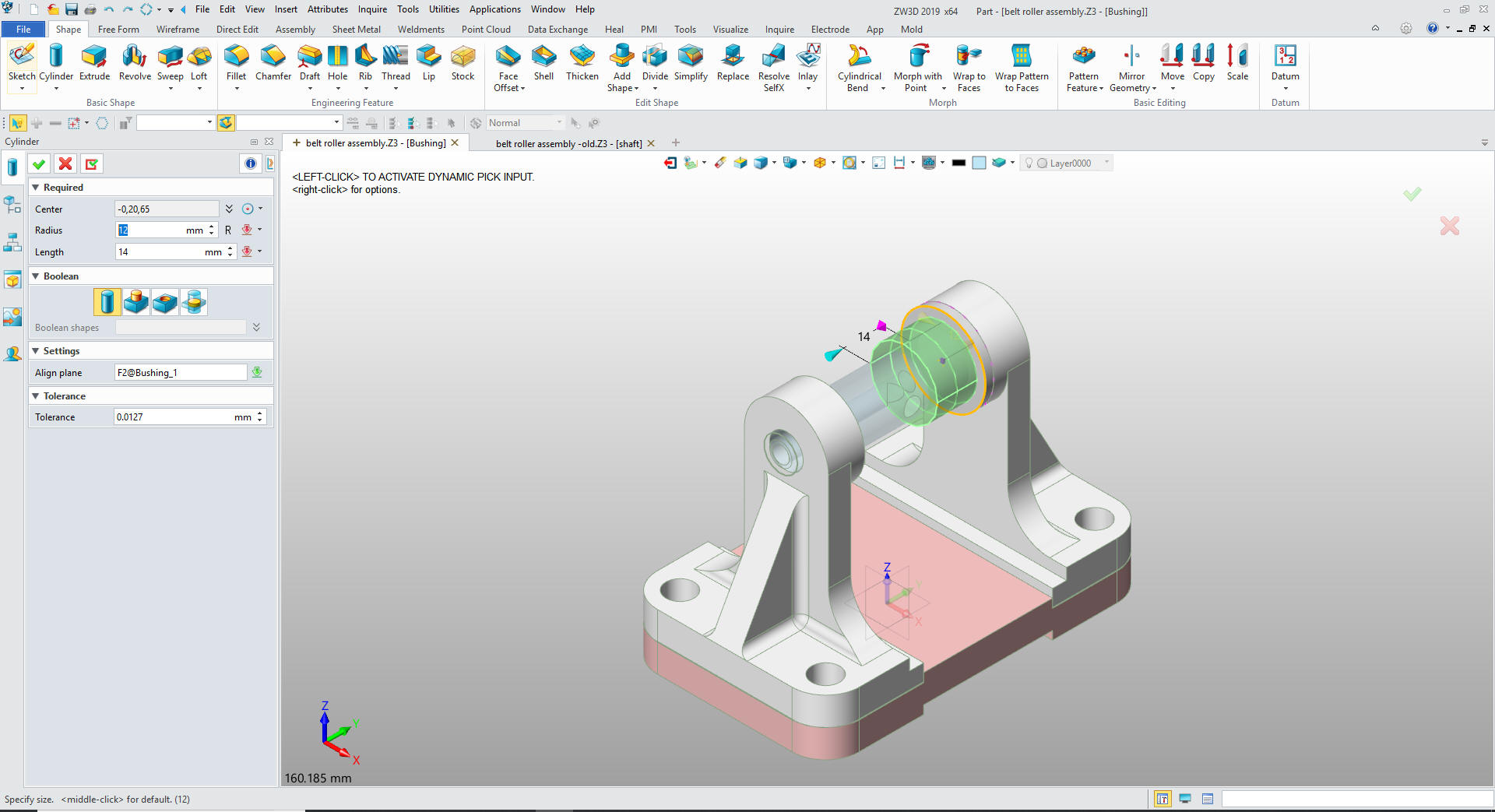

Add

the shaft but inserting another primitive cylinder, locate and set

the diameter and length.

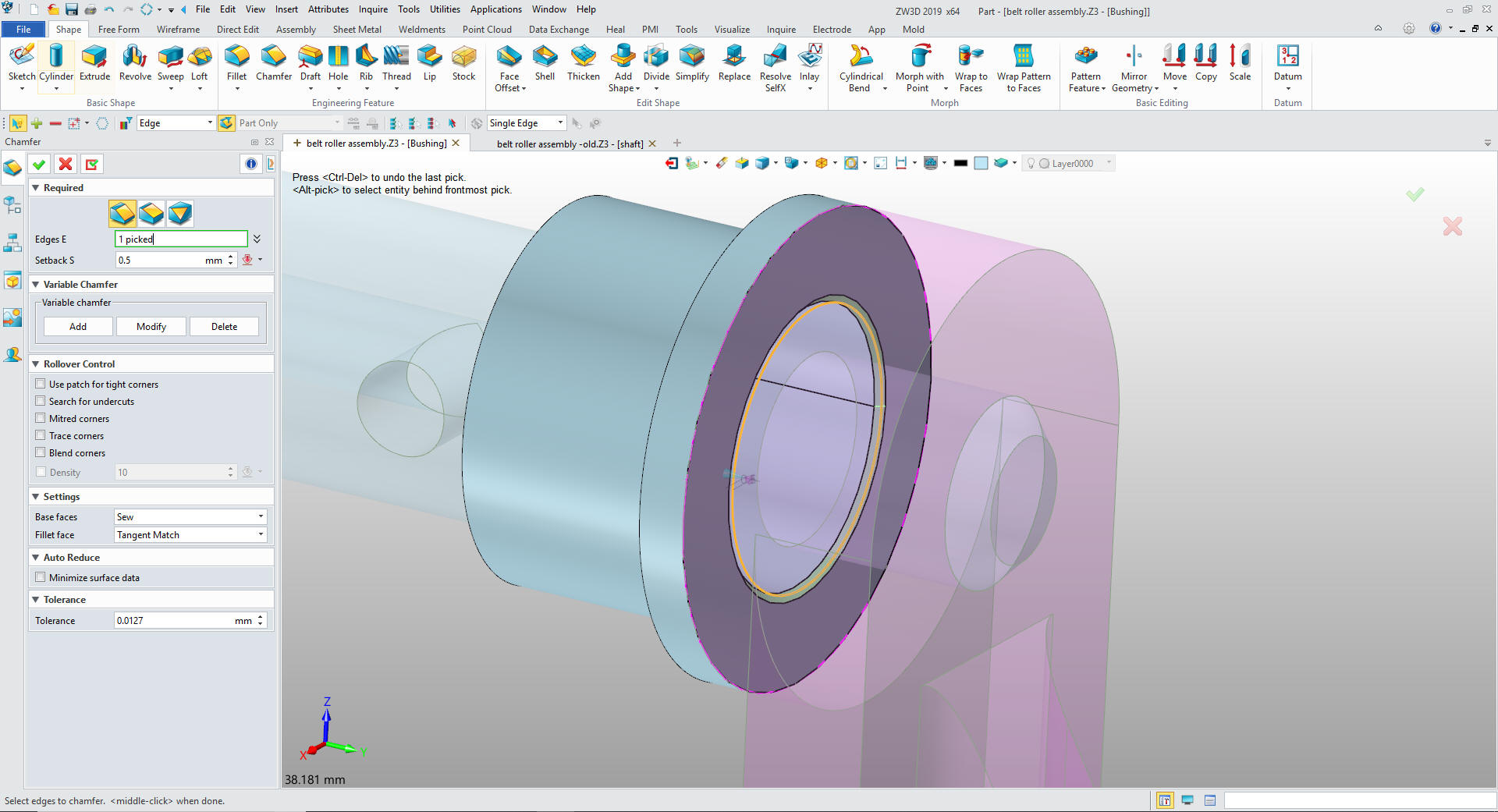

Now

for the chamfer and another primitive cylinder. I am sure all of you

have gotten the idea how this works by now

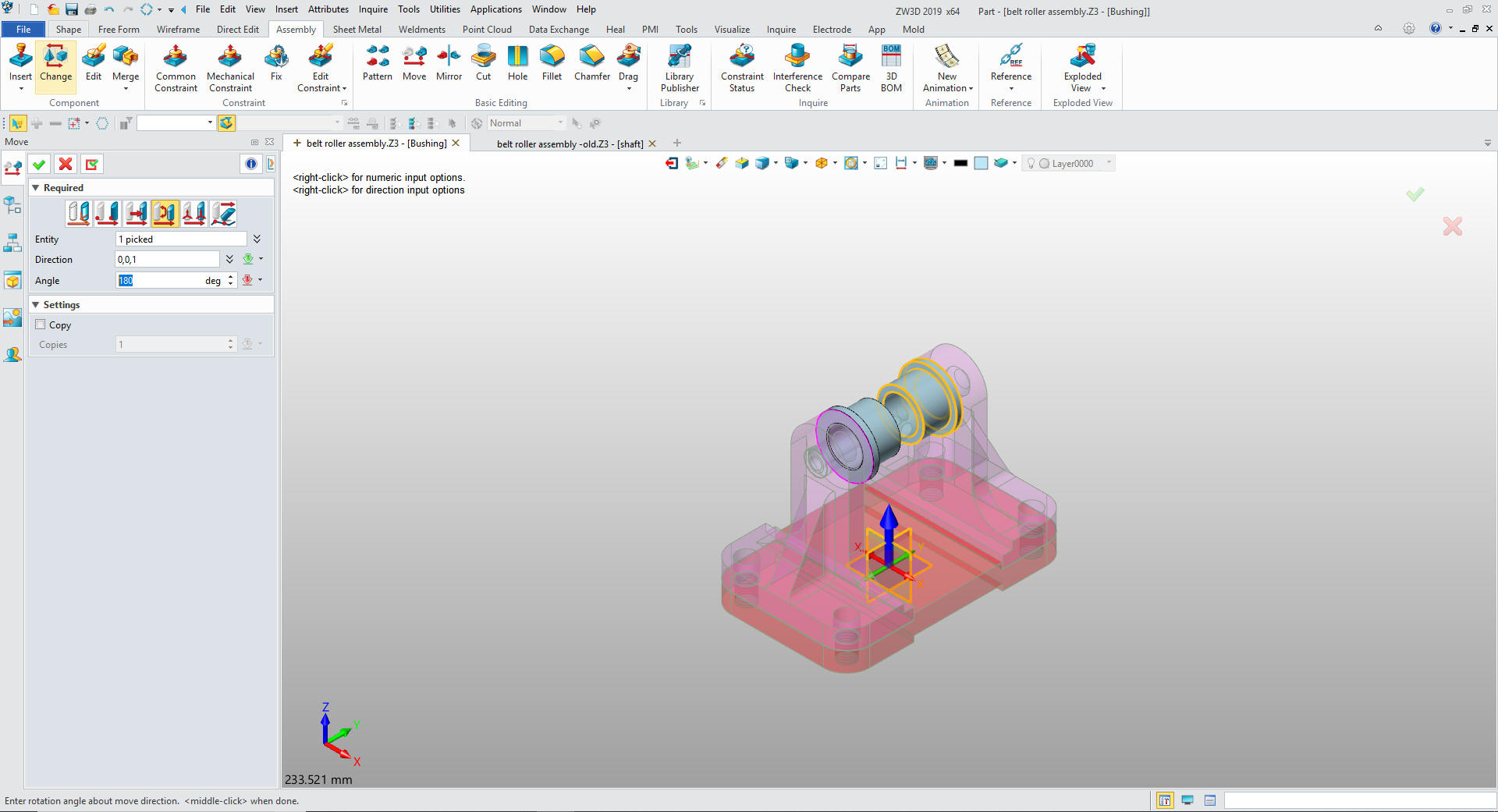

Since

there are two bushings we will copy another one and locate it.

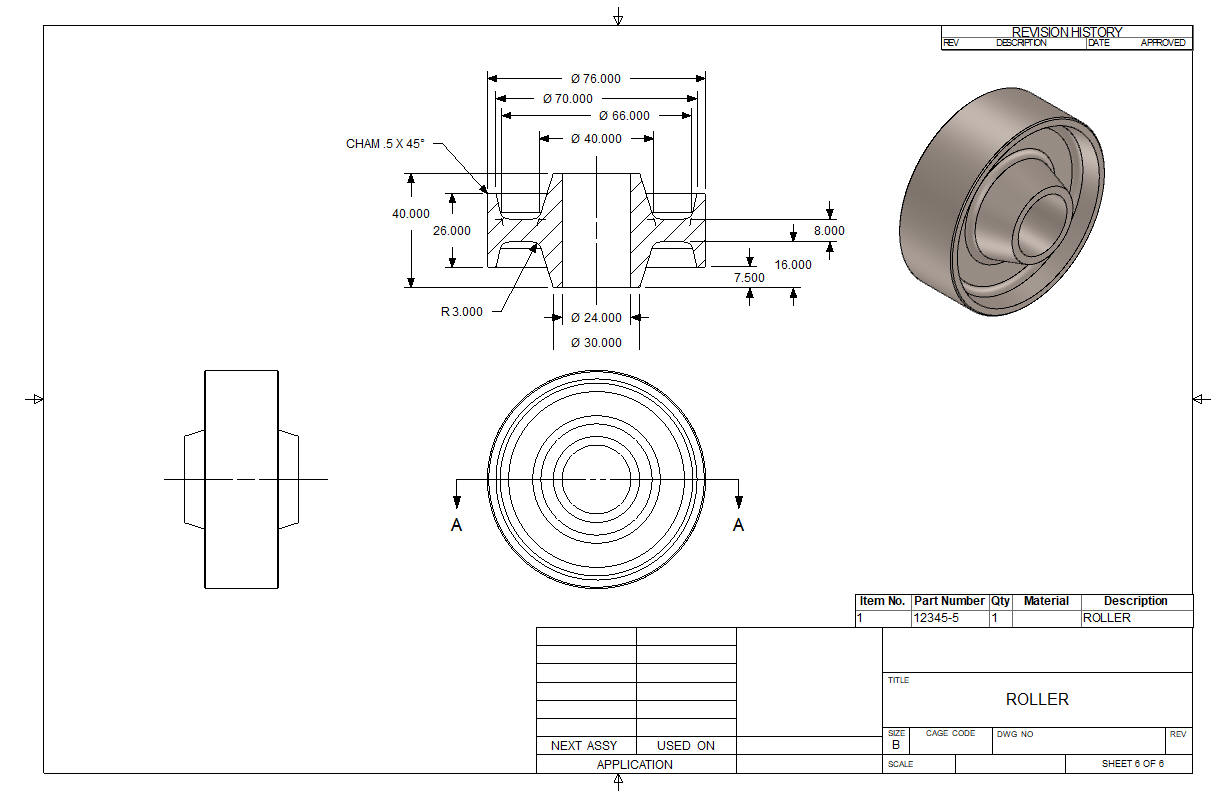

We

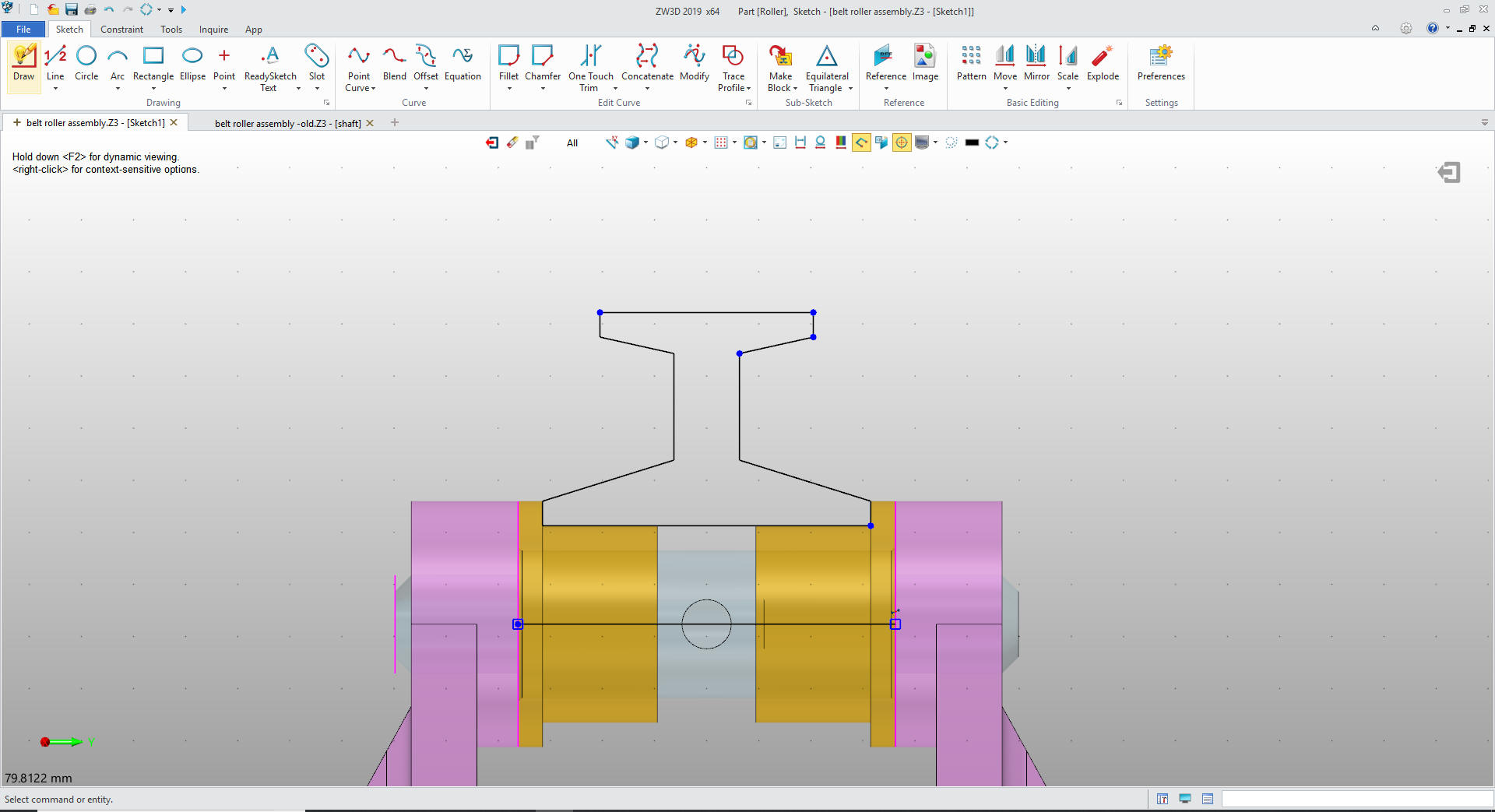

will add a component Roller by creating as sketch. Since I will be

using Streamlined Sketching I will create a couple of reference

lines.

I will create my parallel offsets.

Now

create the edges of the roller by connecting the dots, trimming,

extending deleting and mirroring. Nope, no constraints.

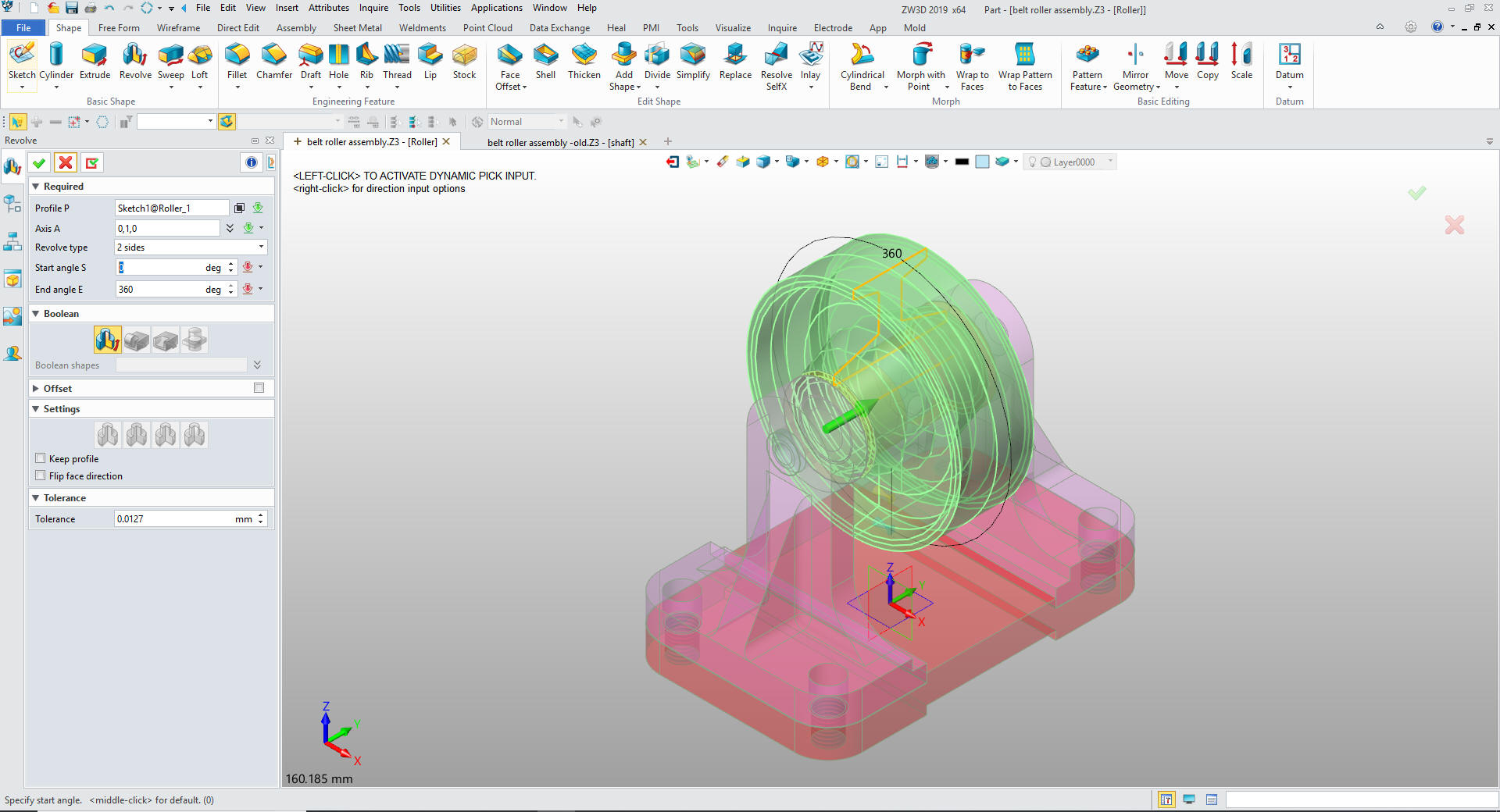

Exit

sketch and select revolve at 360 degrees.

We

add the chamfers and fillets and we are done.

Now

we insert the washers and screws and pattern them and we are done.

Here is the assembly.

Here are the drawings.

Think of the amount of

files created with Solid Edge, the five parts and one assembly, if

you create the AIDs (Associated Information Documents (drawings))

that is a total of eleven files to maintain. In ZW3D there is one

file due to the integrated drawings.

It is very important that you look into

how you or your engineers are creating the parts. Streamline

Sketching and Feature Based Modeling is easy to learn and implement.

It, alone, can increase productivity 10X. Now, ZW3D with its unique

history and robust direct edit functionality can increase your

productivity another 5X or more with changes! Again, time is money

in engineering.

More on Streamline Sketching and Feature Based Modeling.

3D Modeling Techniques Defined

To experience this increased level of

productivity, please download ZW3D for a 30 day evaluation. Legacy

data is no problem, ZW3D can read the native files of all of the

popular programs including the PMI data of NX, Solidworks, Catia and

Creo. ZW3D is a great replacement for the subscription only Autodesk

and PTC products.

For more

information or to download ZW3D

Give me a call if you have any

questions. I can set up a skype or go to meeting to show this part

or answer any of your questions on the operation of ZW3D. It

truly is the Ultimate CAD/CAM System.

Joe Brouwer

206-842-0360

TECH-NET Engineering Services! | |