|

IronCAD is unique and the most productive

conceptual 3D CAD system. Change is incredibly easy. You can have

several iteration of your design in the same file.

- Single Model Environment - Parts and

assemblies in a single file

- Drag and Drop Design from Custom or

Standard Catalogs

- The Only Integrated History/Direct

Edit Design - Both used in your design process

- Copy and Paste Directly from Different

Files

- The Incredible Feature, Part and

Assembly Manipulator - The Triball

We have the native IronCAD and STEP File Available here for download

Note: IronCAD Model .ics/AID .icd native

files must be copied to the same folder.

3D Modeling is the basis for our

engineering. That is the only place where productivity is paramount.

You can have all the PLM/MBE gurus debating data management, but it

does not add one smidgeon of productivity to the design process.

Top down or In-Context modeling is the most productive

feature of 3D CAD. Most systems tout this but each part is still an

external part. We are talking about a single model or multi-object

design environment. Both of the systems we represent offer this as

the "normal" design process. Thereby increasing your productivity 20

to 30%.

In these exercises I not only focus on modeling techniques, but

also on much more productive systems to do our designs. I hope you

enjoy them and learn something. If you are in management, understand

that all 3D CAD systems are not the same. Cutting your engineering

costs is very simple. Even your legacy data is not a problem. Please

feel free to give me a call. There are millions of man hours wasted

every day with poor modeling techniques and dated 3D CAD

systems that cost a fortune. Productive 3D CAD systems do not have

to be expensive.

Joe Brouwer

206-842-0360

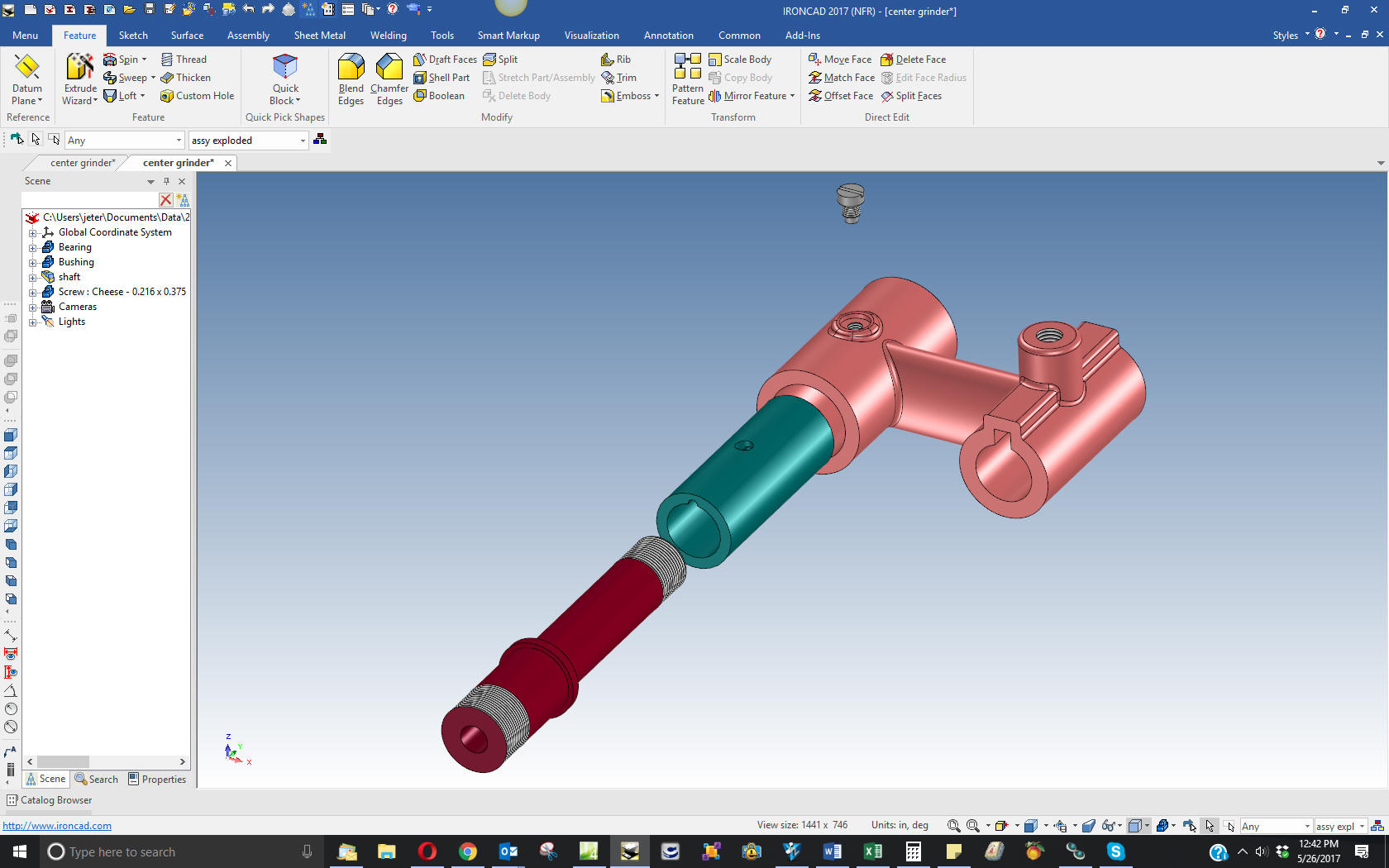

I am doing the below assembly for

an exercise showing my modeling techniques and, of course, my 3D CAD

solutions.

When I introduce IronCAD's very

flexible design paradigm I have a hard time to get the Pro/e clone

users, like Solidworks and other programs to understand the drag and

drop design paradigm.

I saw some video challenges on linkedin and thought I would give it a

try on IronCAD. This will give you an idea how different

and flexible IronCAD is compared to the conventional Pro/e clone and

to the not so conventional Fusion 360.

These exercises started out to show the benefits of IronCAD over Fusion 360, but

quickly turned into a study of modeling techniques. Take a look at all of

them, they will open your eyes to a much different and more productive way of

modeling. It really has more to do with modeling technique than it has to do

with the 3D CAD systems. I have found that I do 3D modeling as compared to

the conventional 2D sketching. Of course, having a more productive 3D CAD

system doesn't hurt.

See the

comparison with many other 3D CAD systems.

3D CAD Modeling Techniques

These exercises were incredibly

popular and I thought I would follow up by showing more examples of

this 3D modeling technique.

We will be doing a

couple of parts each weekend in both IronCAD and ZW3D. I hope you

enjoy these exercises and hopefully they may lead to increasing your

productivity.

Please feel free to review the first

lesson:

3D Modeling Techniques IronCAD Lesson One

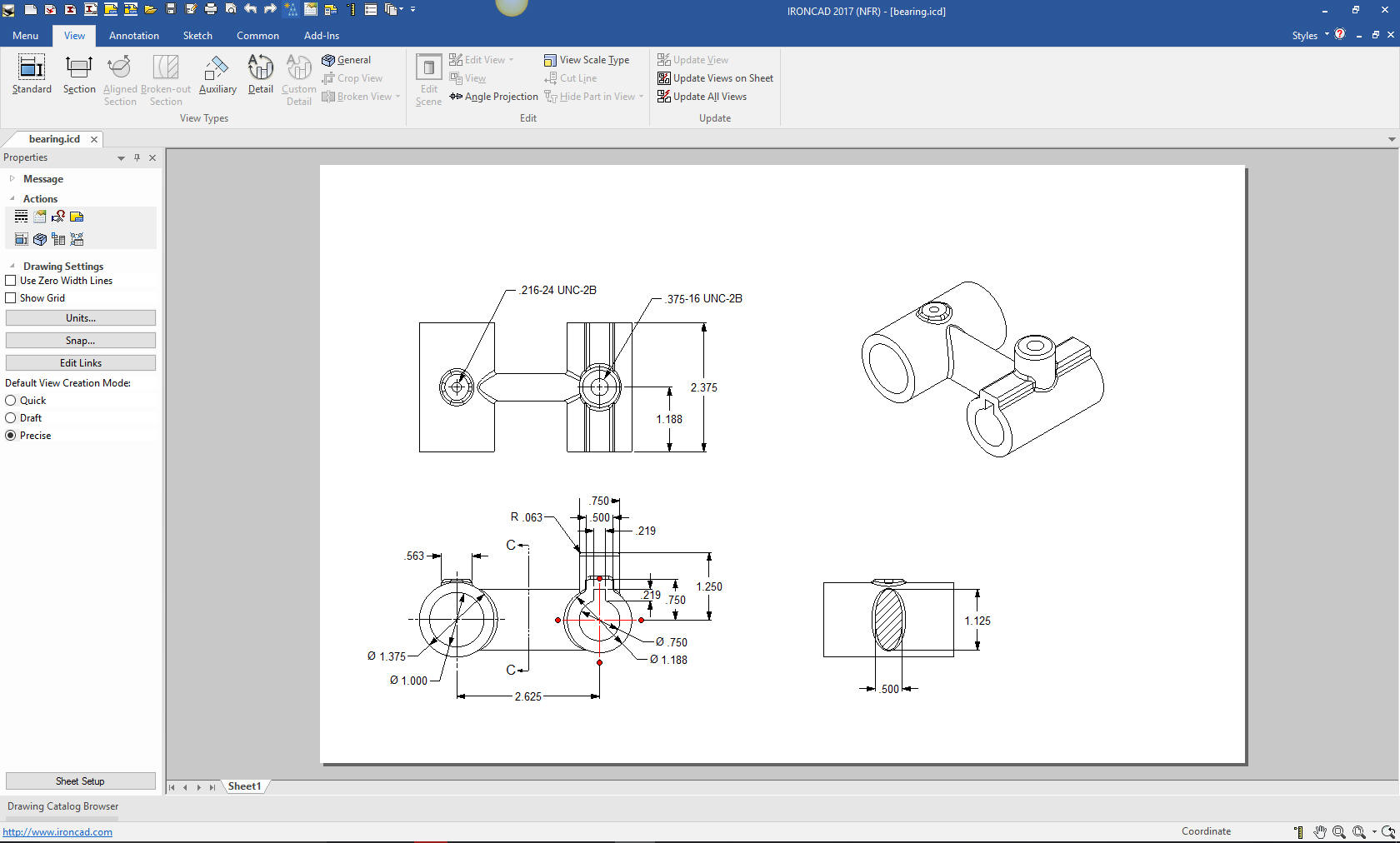

I was a bit short sighted last week with the Bearing. I

named the file "Bearing" when it should have been "Center Grinder".

There is a couple of ways to get the Bearing into another file. You

can import it, copy and paste from another file or just rename the

file. I had a document attached and I want to keep that document

tied to the related model file so I will have to

save it as the new name.

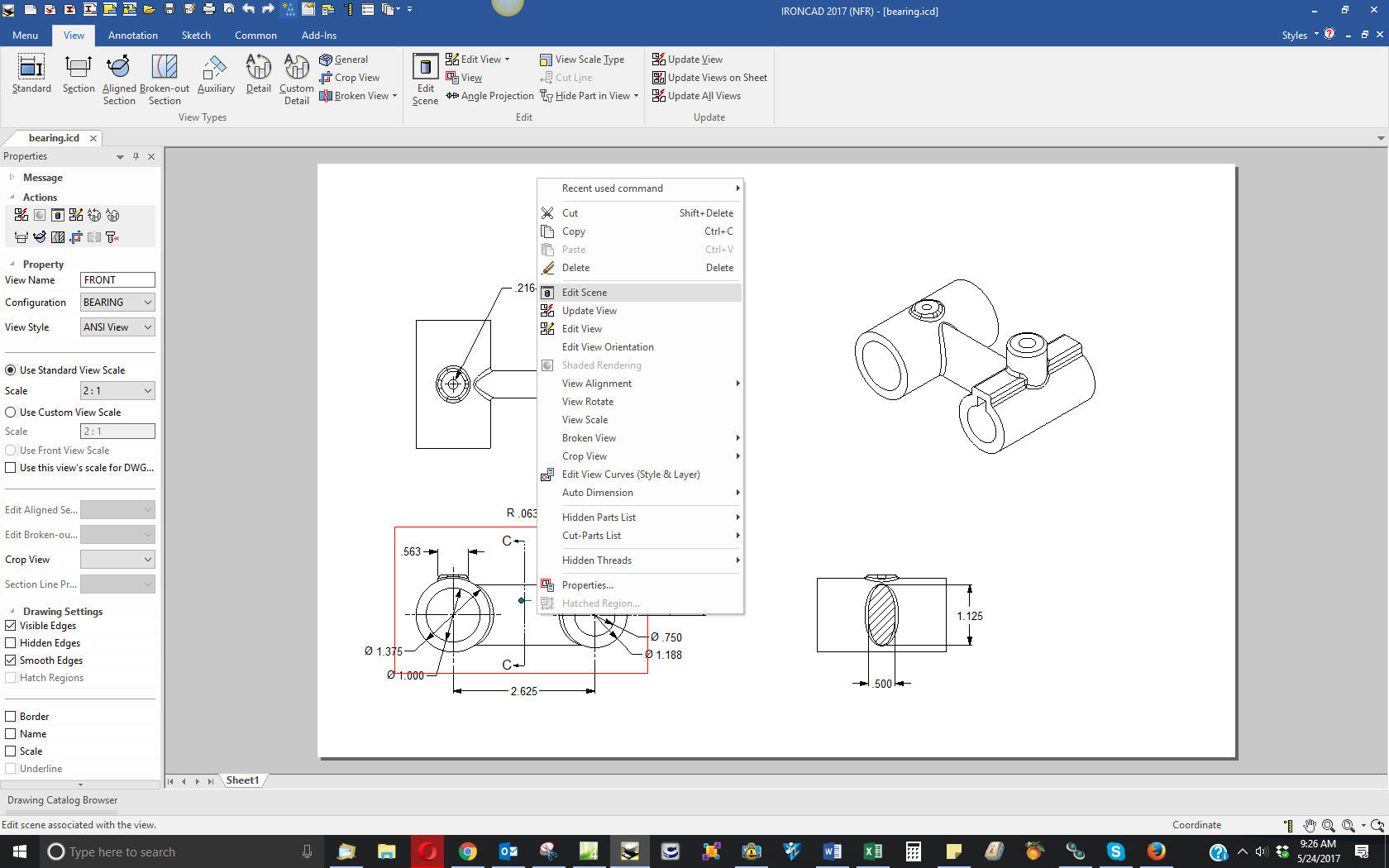

I bring up the document file:

Bearing.icd

I right click on a view and select edit scene.

It will bring me to that configuration in the model file and the relative view.

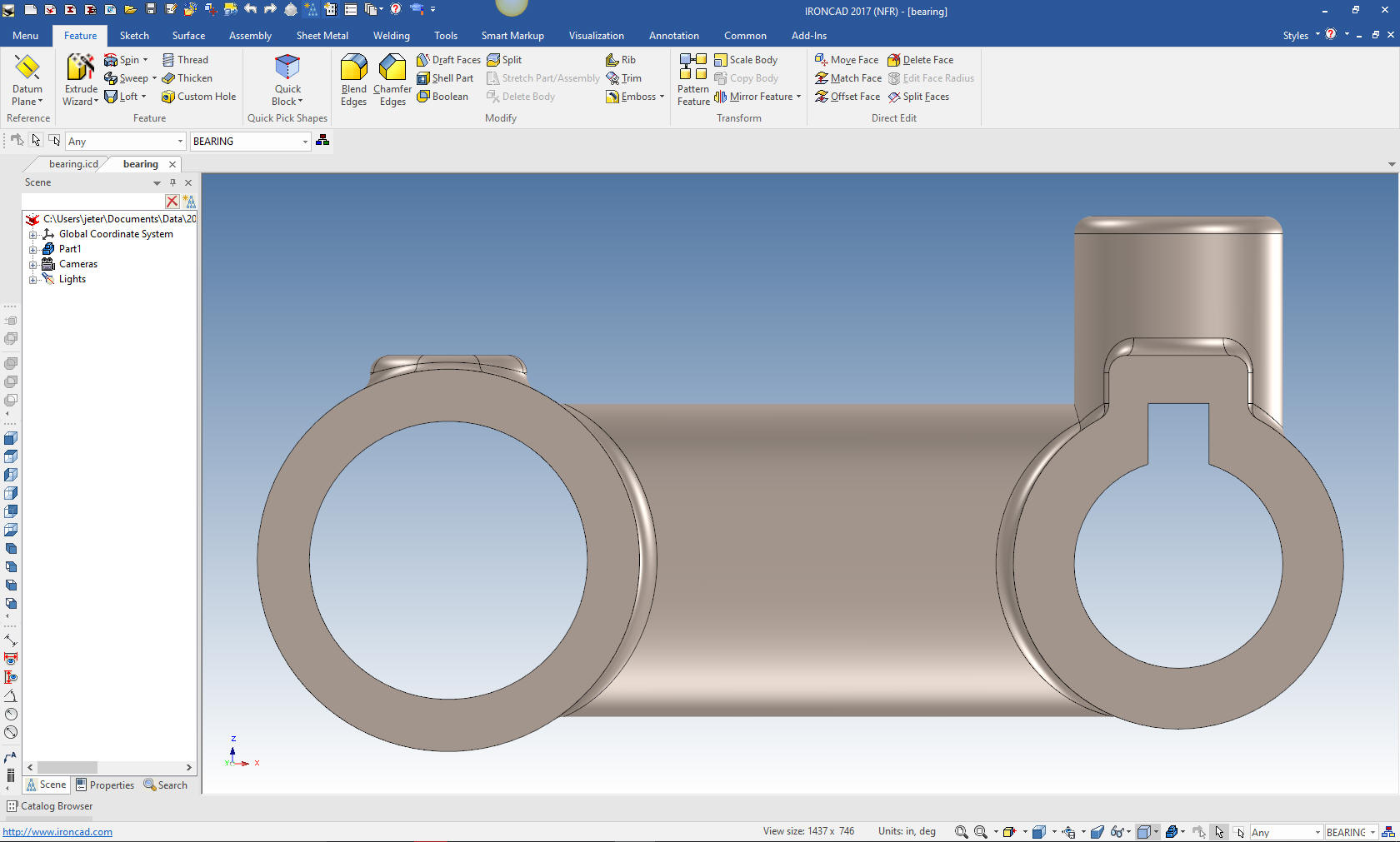

Now we have the related scene and

configuration. Why scene? IronCAD was based on a graphic design

package called "Trispectives" and scene would be appropriate. That

is why IronCAD has integrated realistic rendering and animation. Why

configuration? IronCAD is a single model environment and you have to

be able to reference the different parts and assembly for drawings

and other modeling functions. Especially when you do many

different iterations of a design.

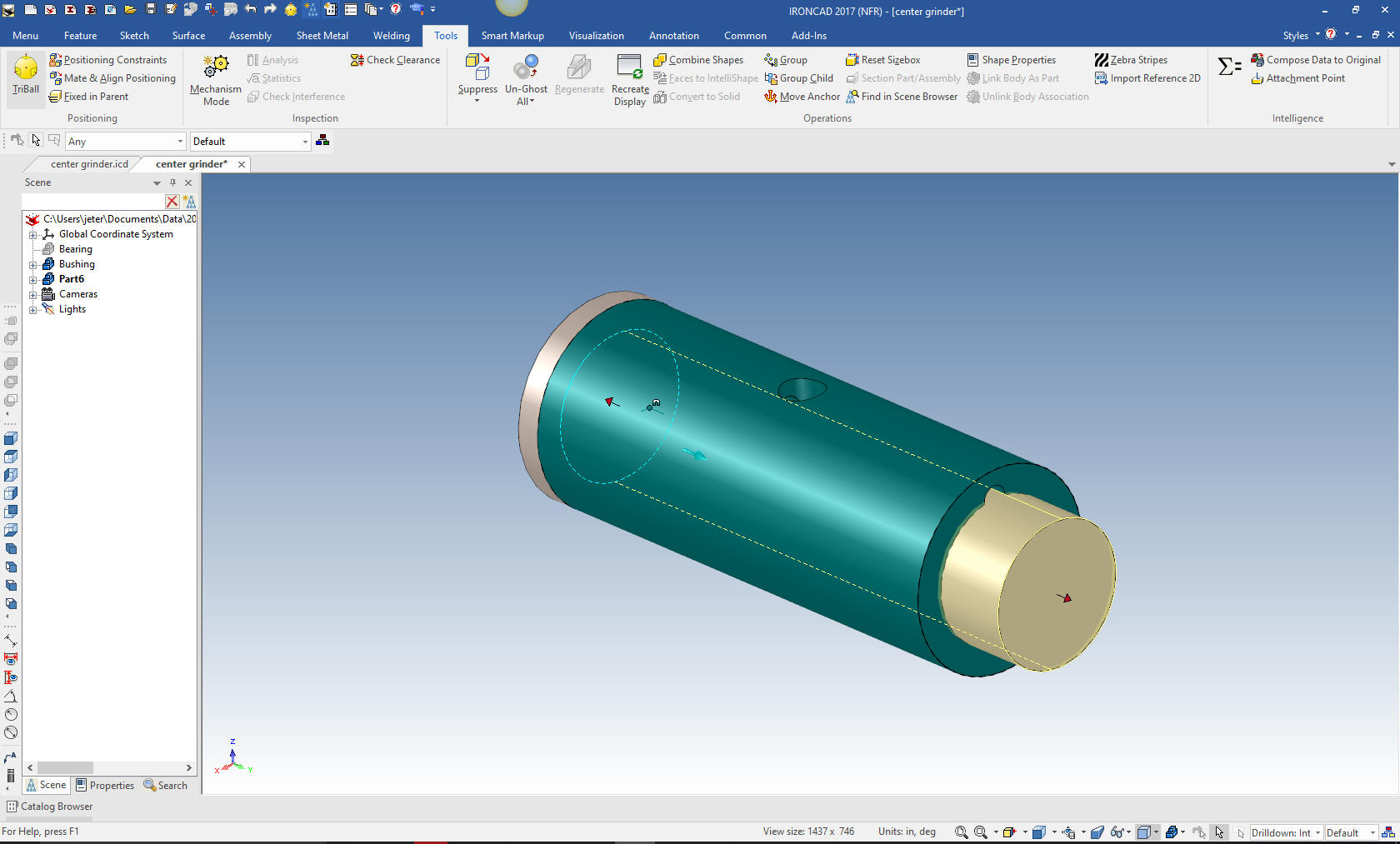

We now see the Bearing.

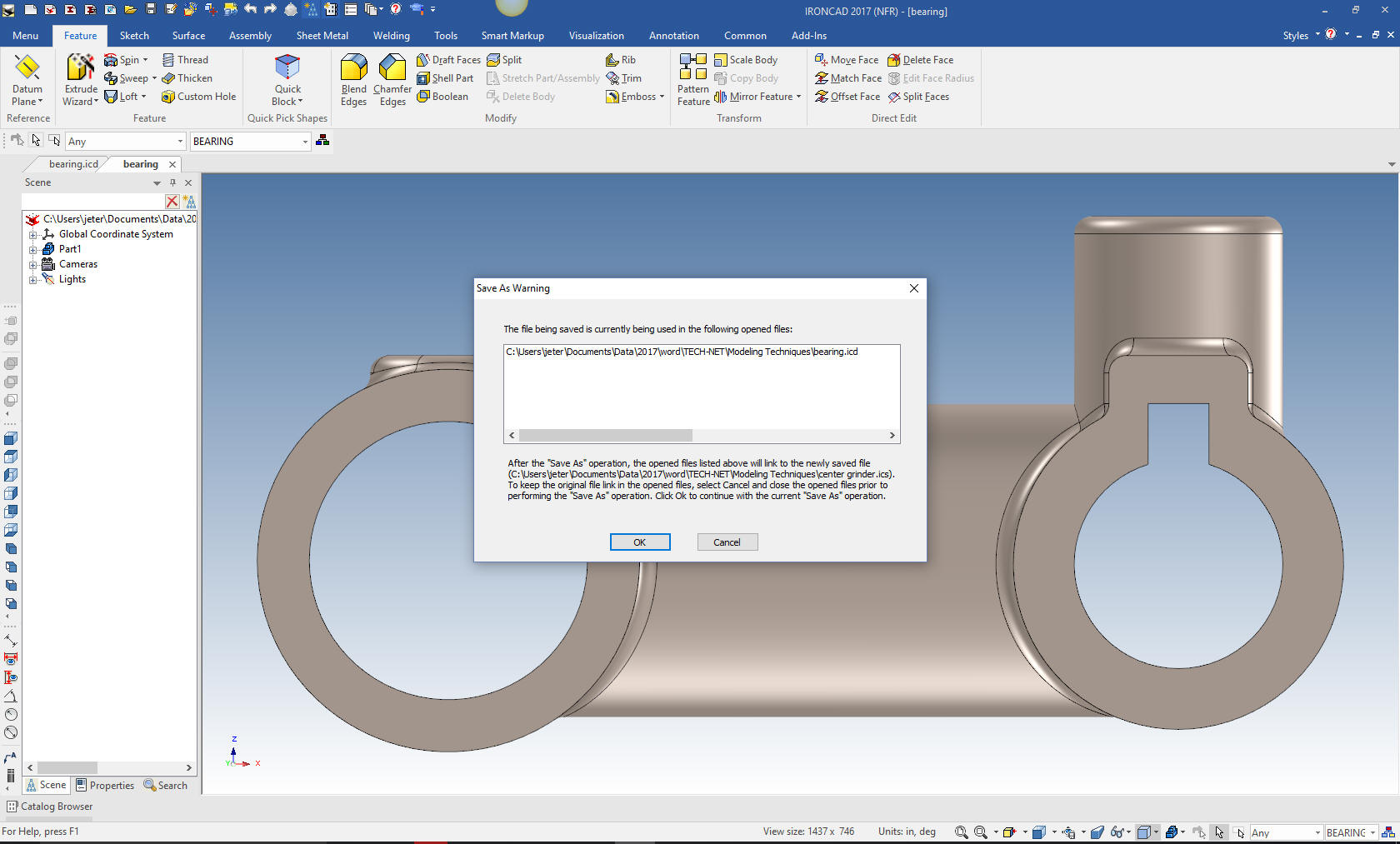

But now we have to save it as "Center Grinder" It gives us an option

to relate the existing bearing document to the new "Center Grinder"

model file.

I will save the bearing document file to

"Center Grinder.icd" so as not to forget. Now we are ready to start

adding parts. We will not detail the parts until the end.

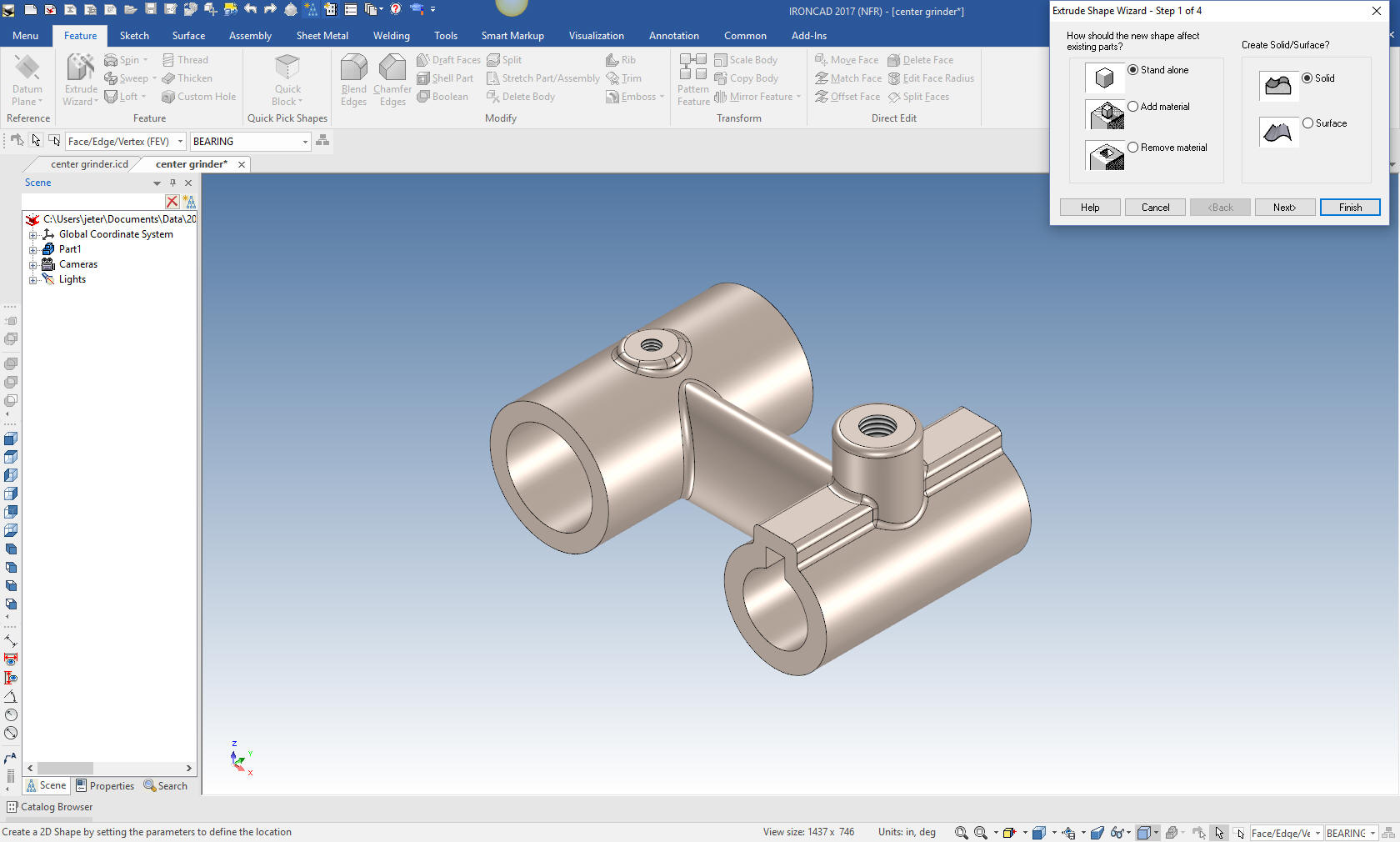

The

first part we will create is the Bushing. We will start by using the

Extrude Wizard and selecting the mating face. We are going to design

these parts in context or top down in the single model

environment. We will change the configuration to default until we

are ready to make the drawings.

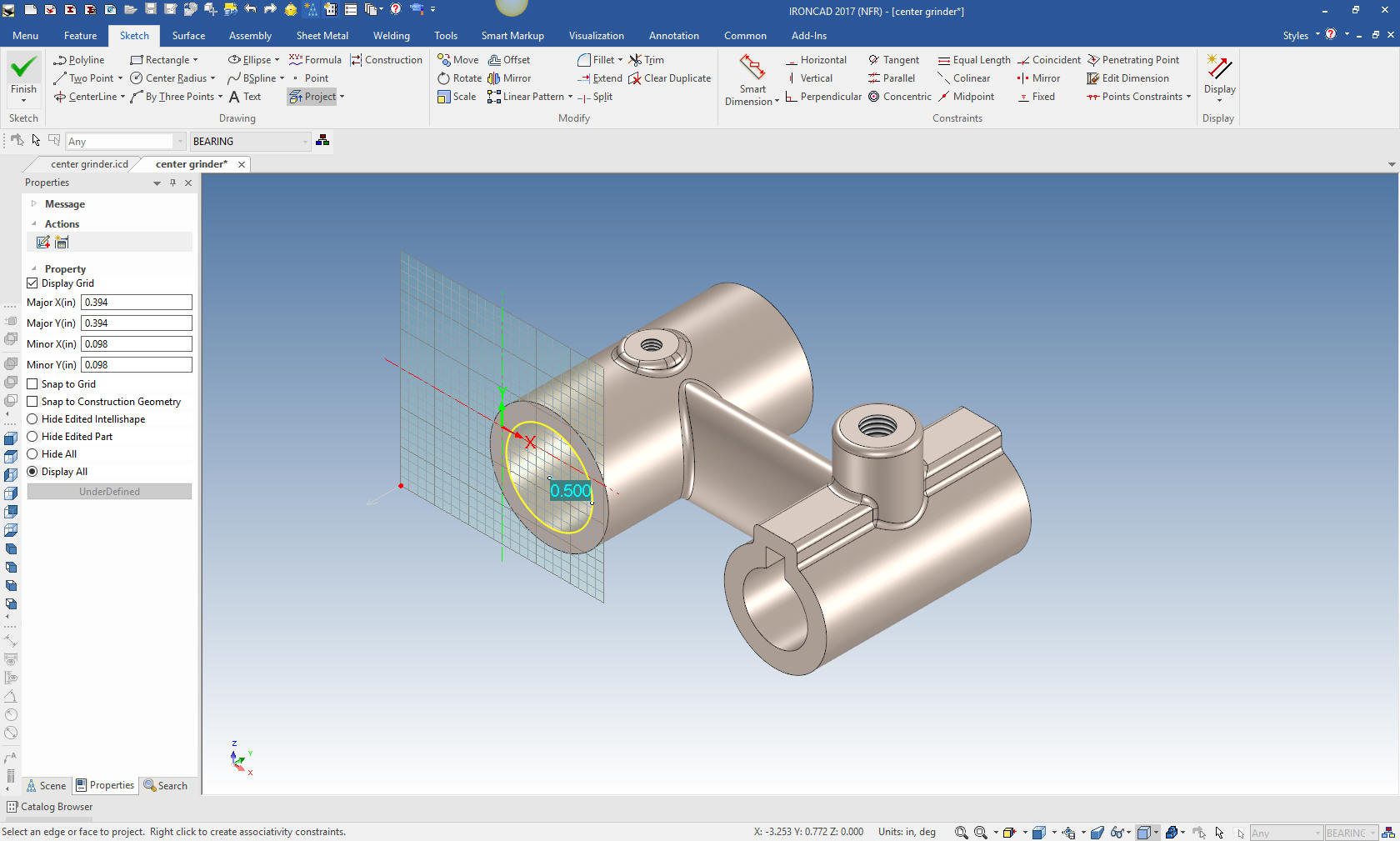

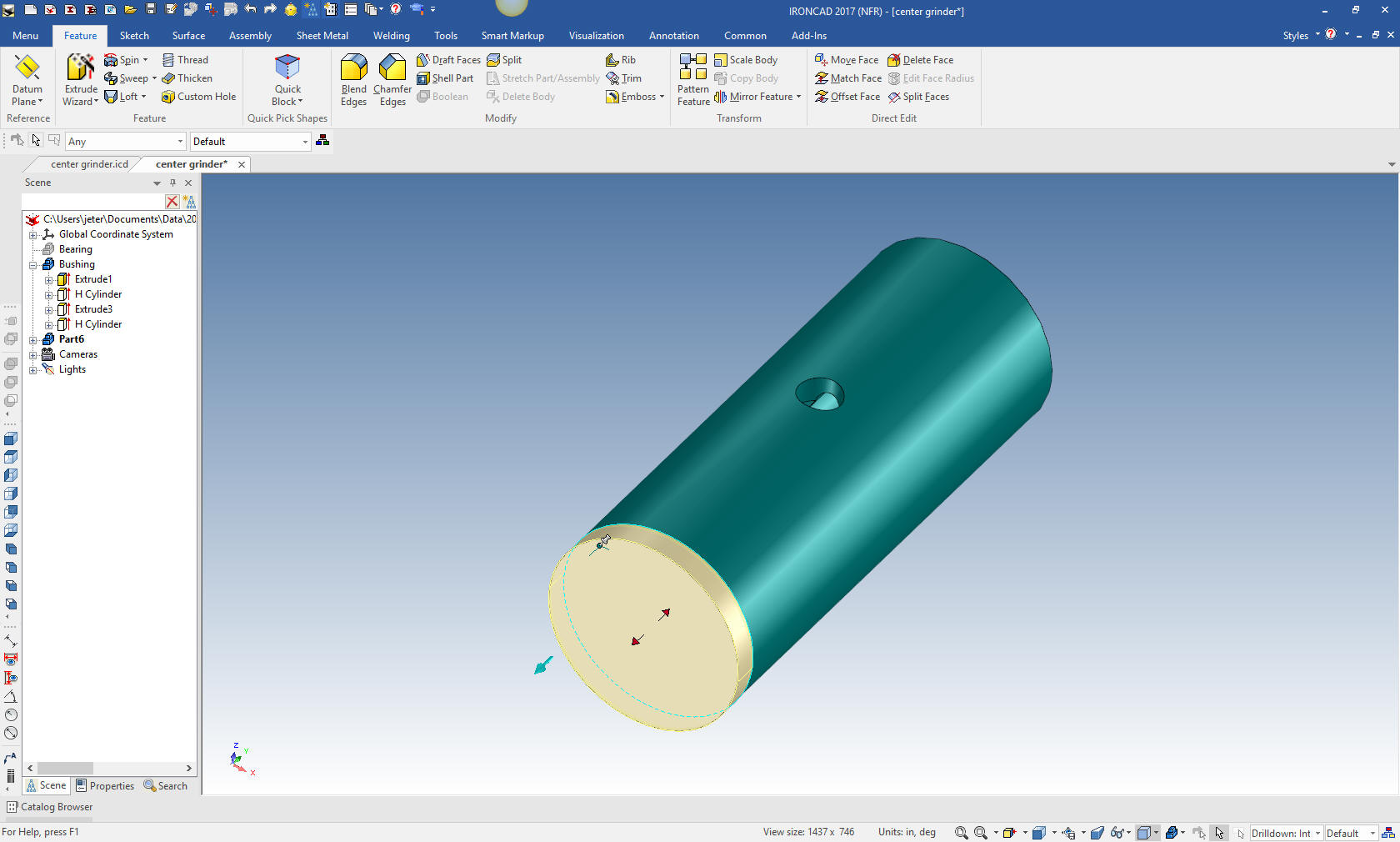

We select the face of the

left cylinder add select standalone part.

This will bring up a sketching plane. Yes, when designing in context

is it much better to use the extrude wizard to project

mating edges.

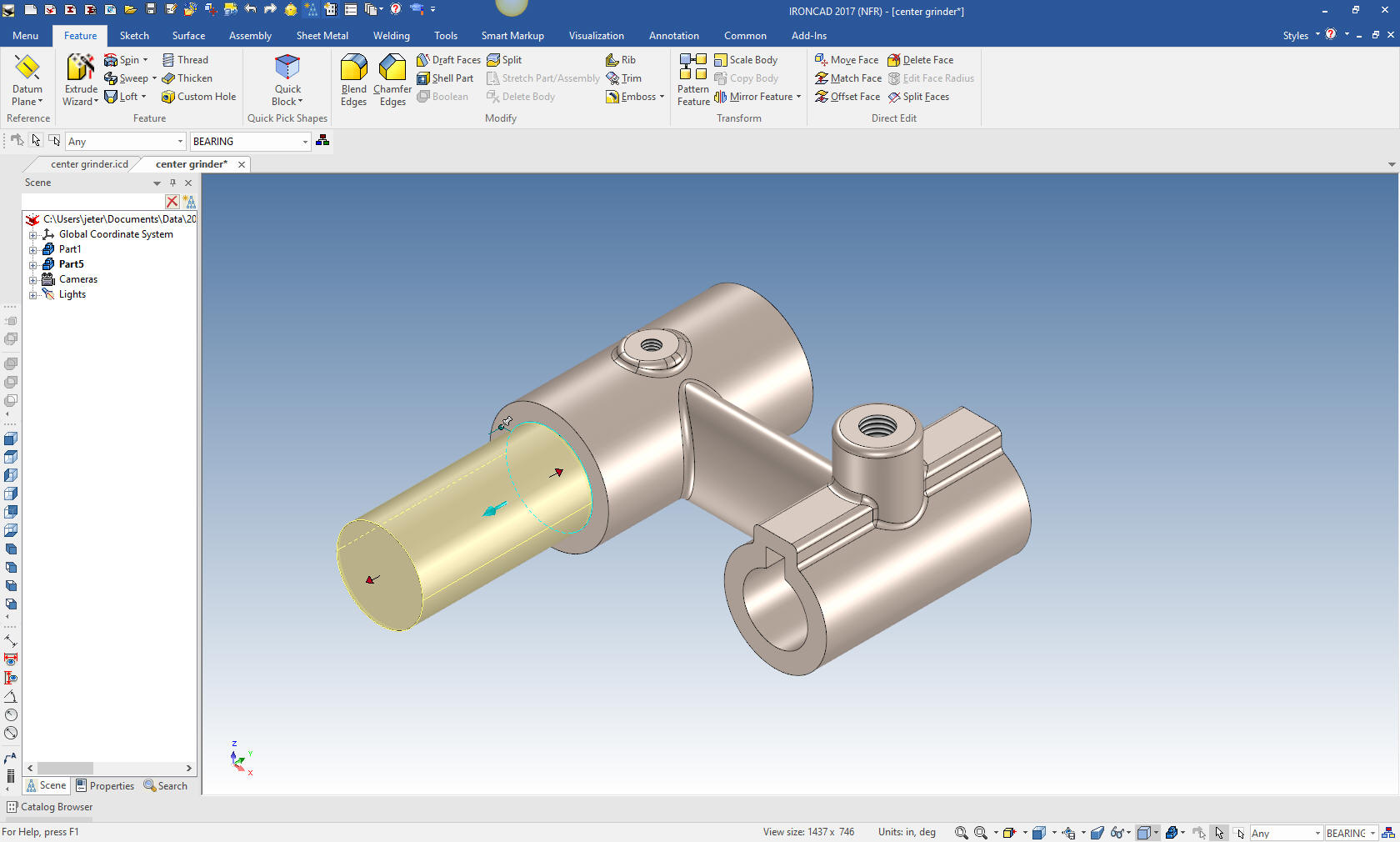

We

select okay and we have our extrusion. But now we have to size it. A

couple of things happened when I did this. I didn't set a direction

or length. I will do that as I size the bushing. If you look at the

scene browser (history tree) you will see a new part created. I am

going to size the bushing change the colors of the parts and rename

the parts in the scene browser.

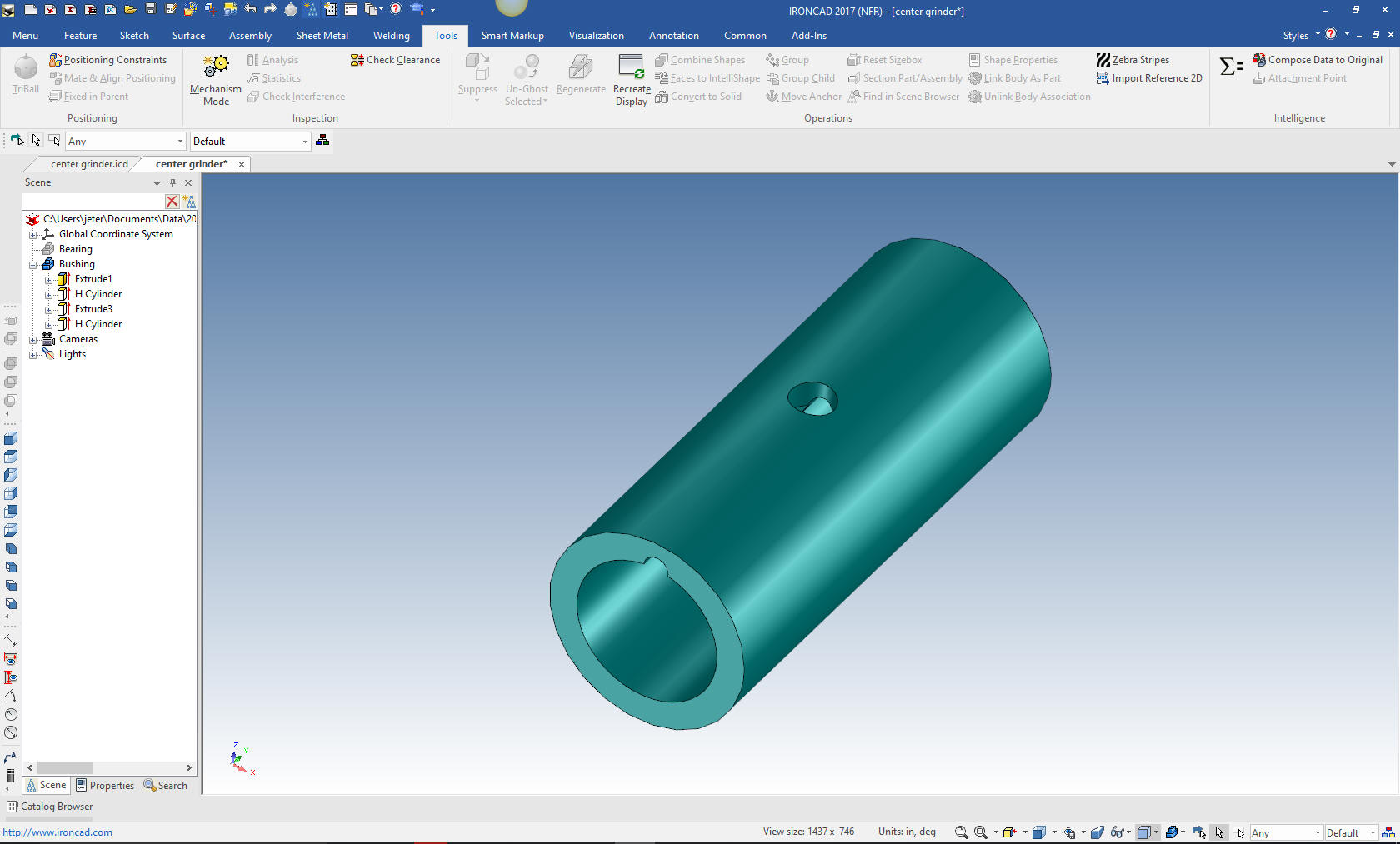

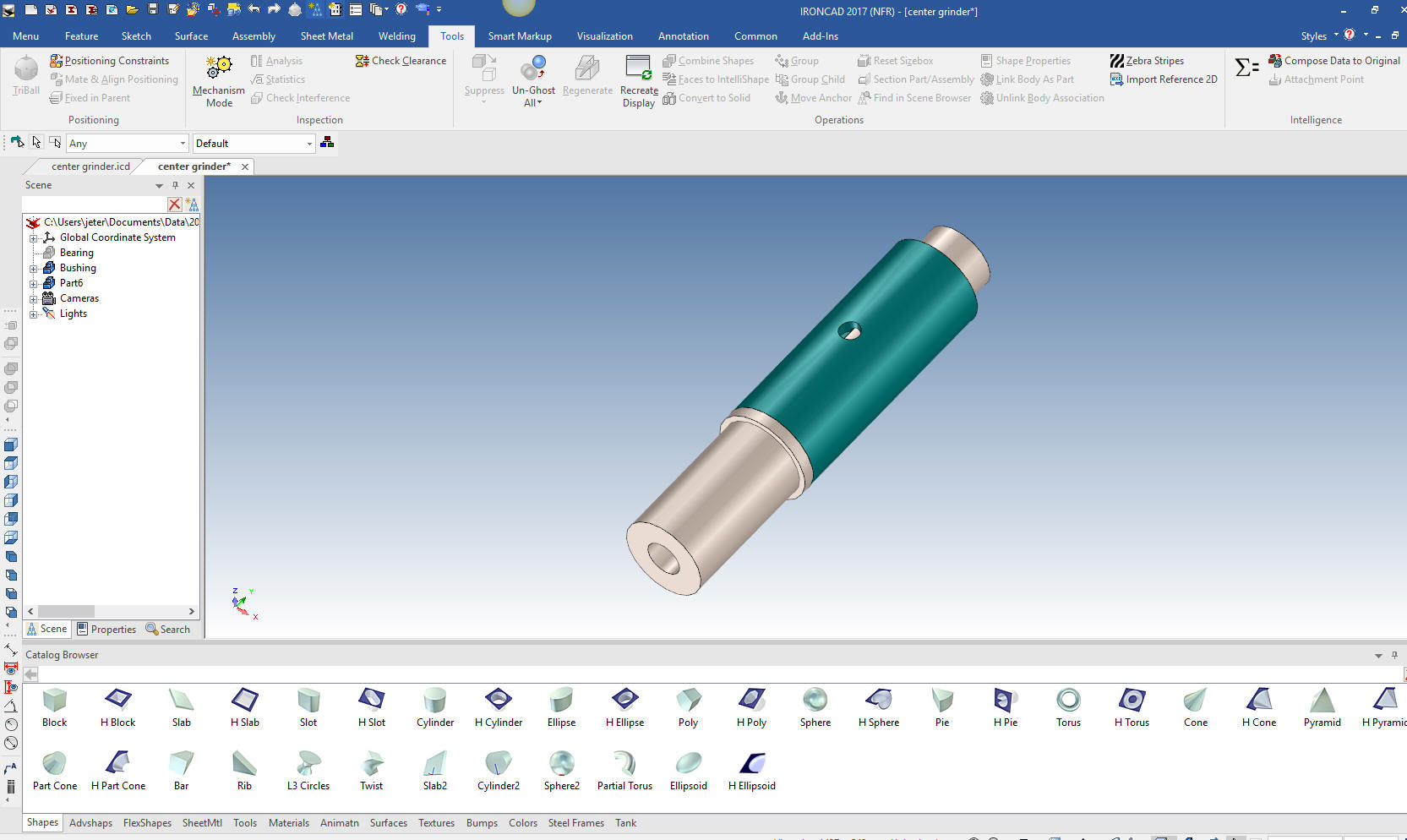

We

drag a hole cylinder to center of the bushing and size it.

I

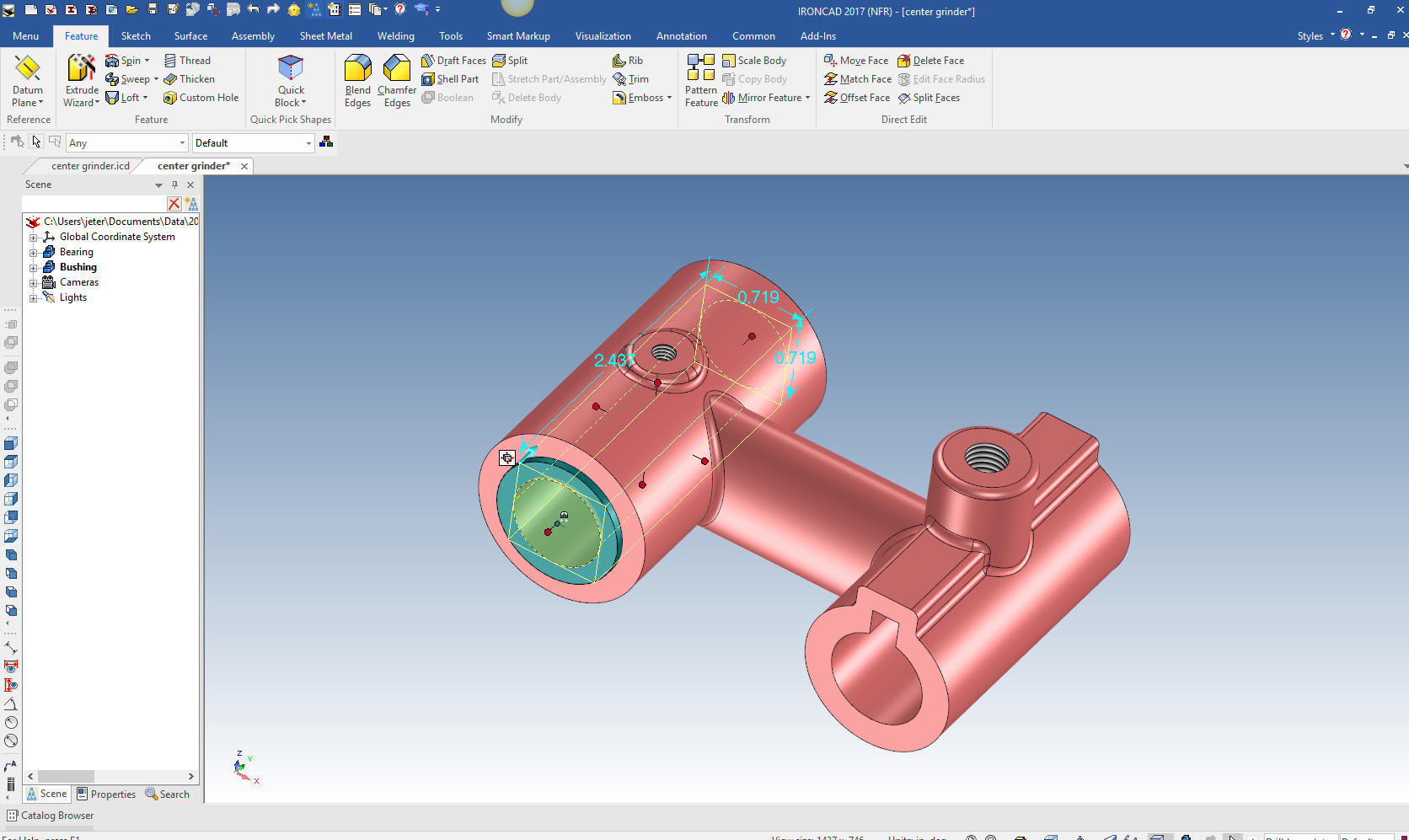

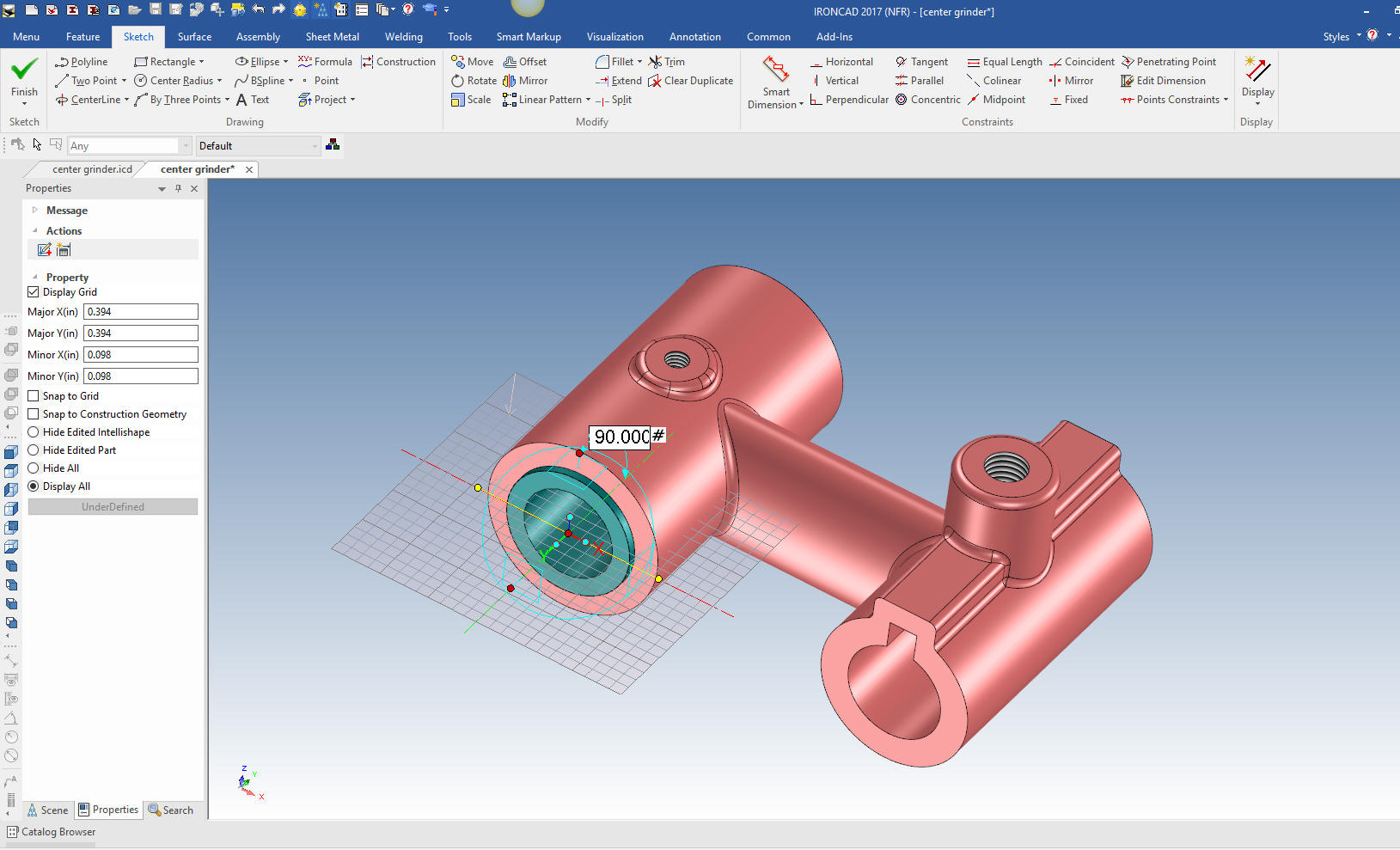

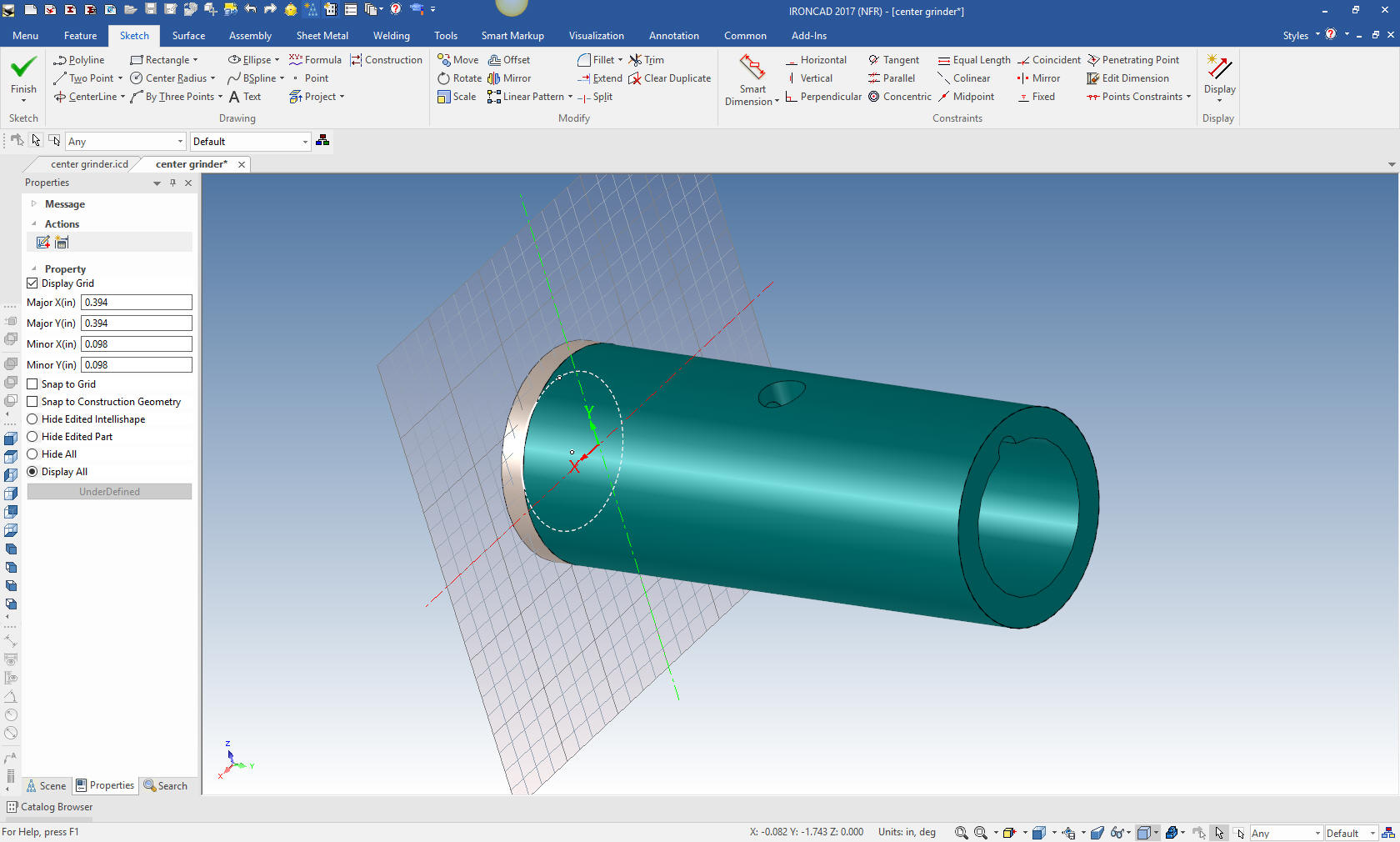

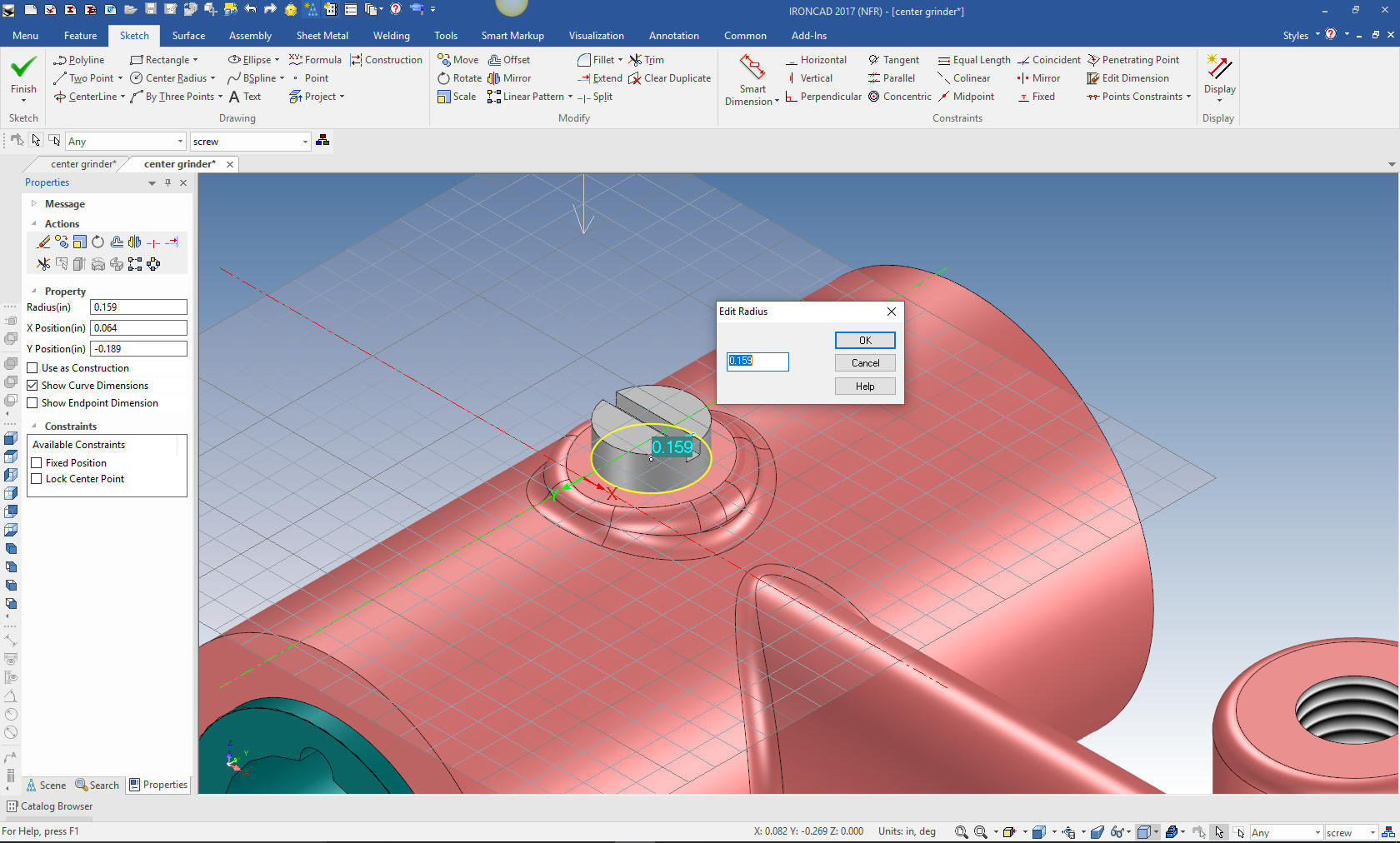

have aligned the bushing so we can add the hole. We do this again

with extrude wizard while the two parts are assembled. We position the

plane on the face of the bushing and rotated it with the triball.

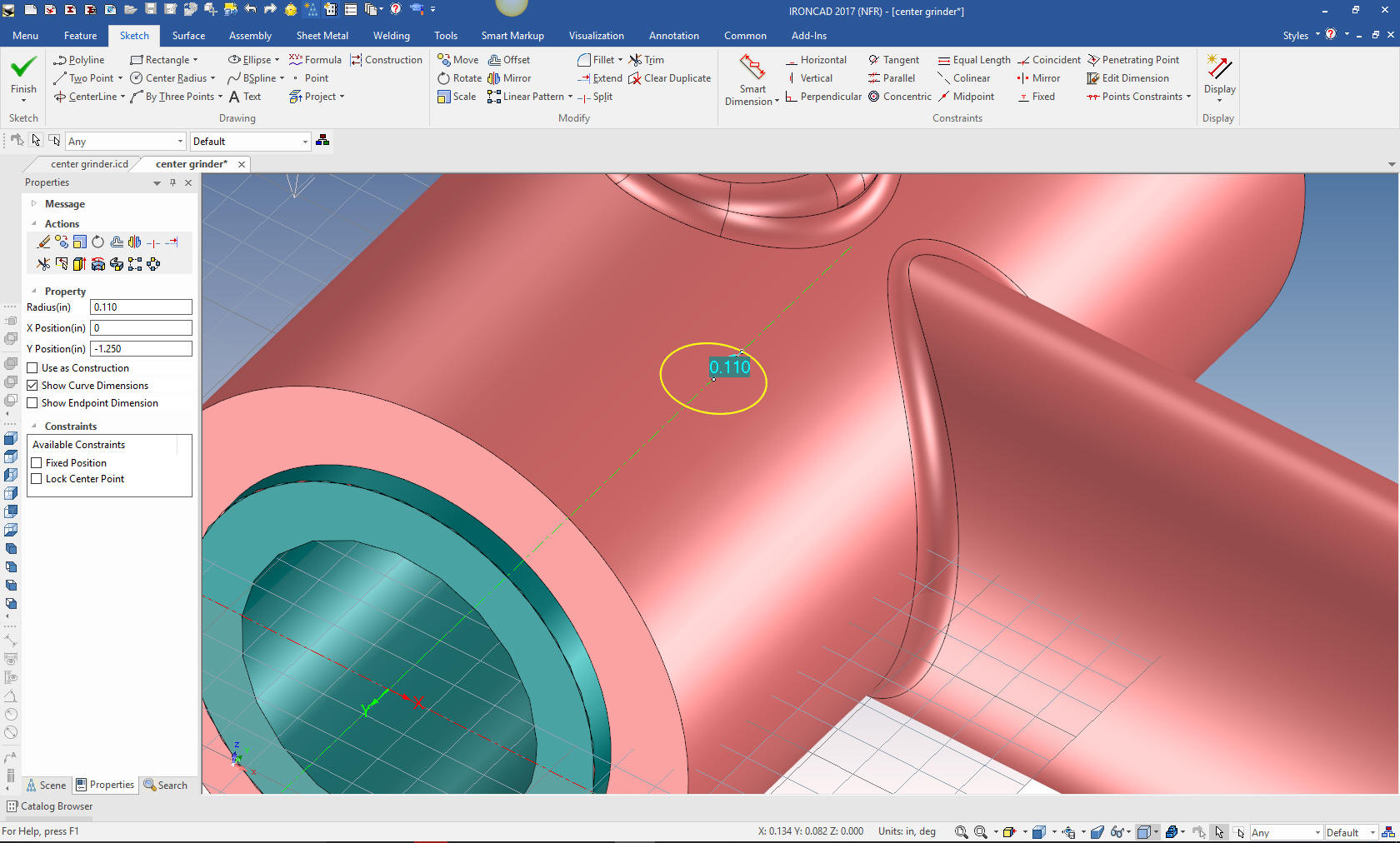

Now we project the hole in the bearing onto the plane. Edit the

radius.

We

will now hide the bearing and add the oil groove by dragging and

dropping a hole cylinder, locating and sizing it. We are done

with the bushing.

Note:

These parts are in aircraft position. This was a concept in very

beginnings of 3D CAD while at Boeing. All of the parts were designed

in their position in the airplane. I was instrumental in bringing

CADKEY on board at Boeing. We would import/export parts to and from

Catia with IGES. The parts "had" to be in aircraft position.

The 1980's - 3D CAD - The Beginning

Now for the Sleeve. Again I select the extrude wizard and project

the edge of the bushing to create the middle cylinder. As you can

see you do not have to worry about inserting a part and aligning it.

It is done at part creation. The time saved in this step alone has

to make you start thinking about design productivity.

Now we

need the far side shaft which again I will use the extrude wizard. I

will project the ID. But I need to create a full circle. I really

doesn't matter where I establish the plane since I can resize it

without a consideration.

We

have sized the shaft and now for the other side.

We

will create the front shaft by dragging a cylinder to the center of

the face size it and then drag a hole cylinder to the center of the

new Sleeve. We can use a mixture of drag and drop, projecting and

sketching as we decide which is the most productive.

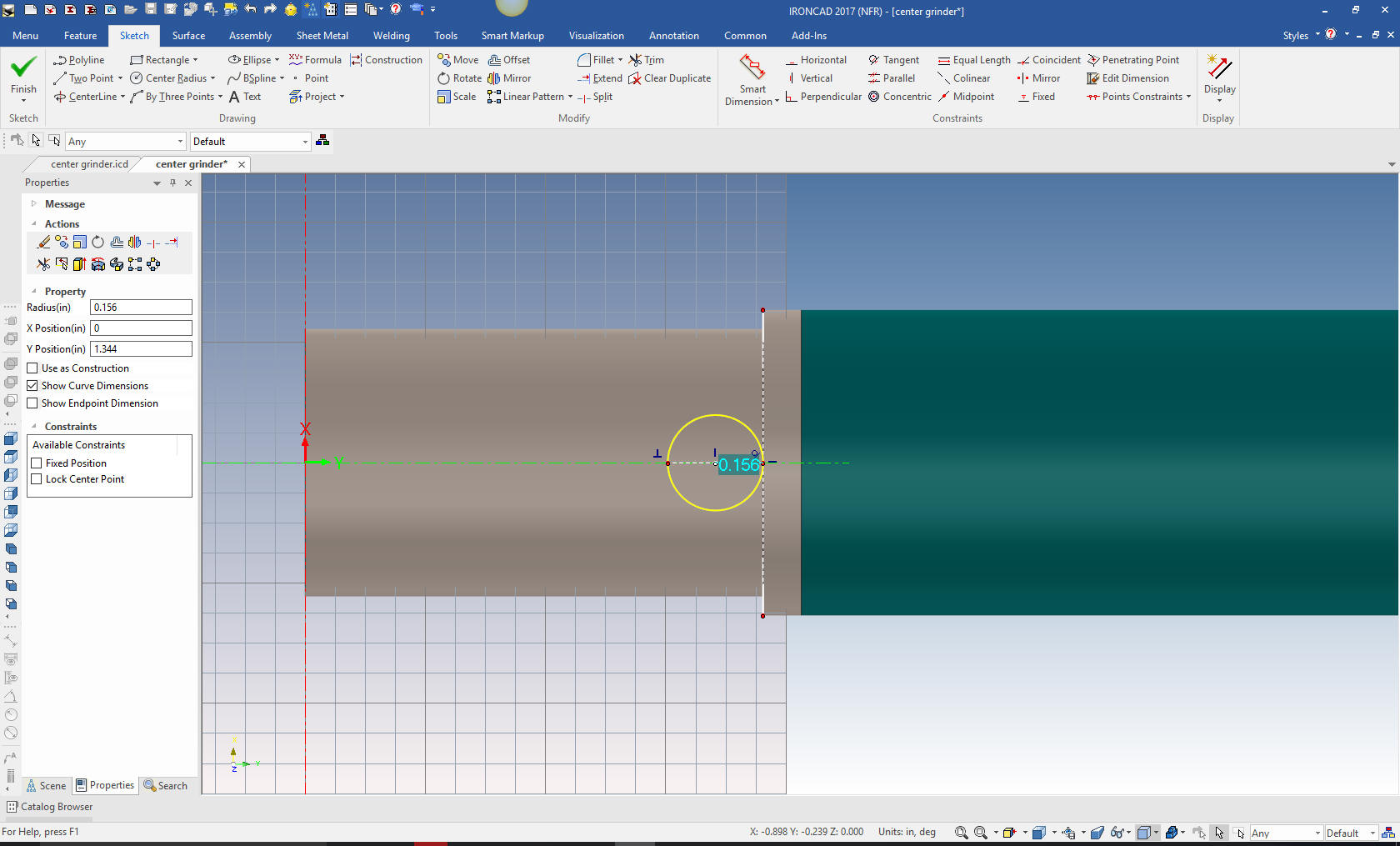

We

need a hole for a small key. Again the extrude wizard is brought

into play. We rotated it to horizontal and sketch the circle.

We

select okay it automatically creates the hole. We will size the

hole.

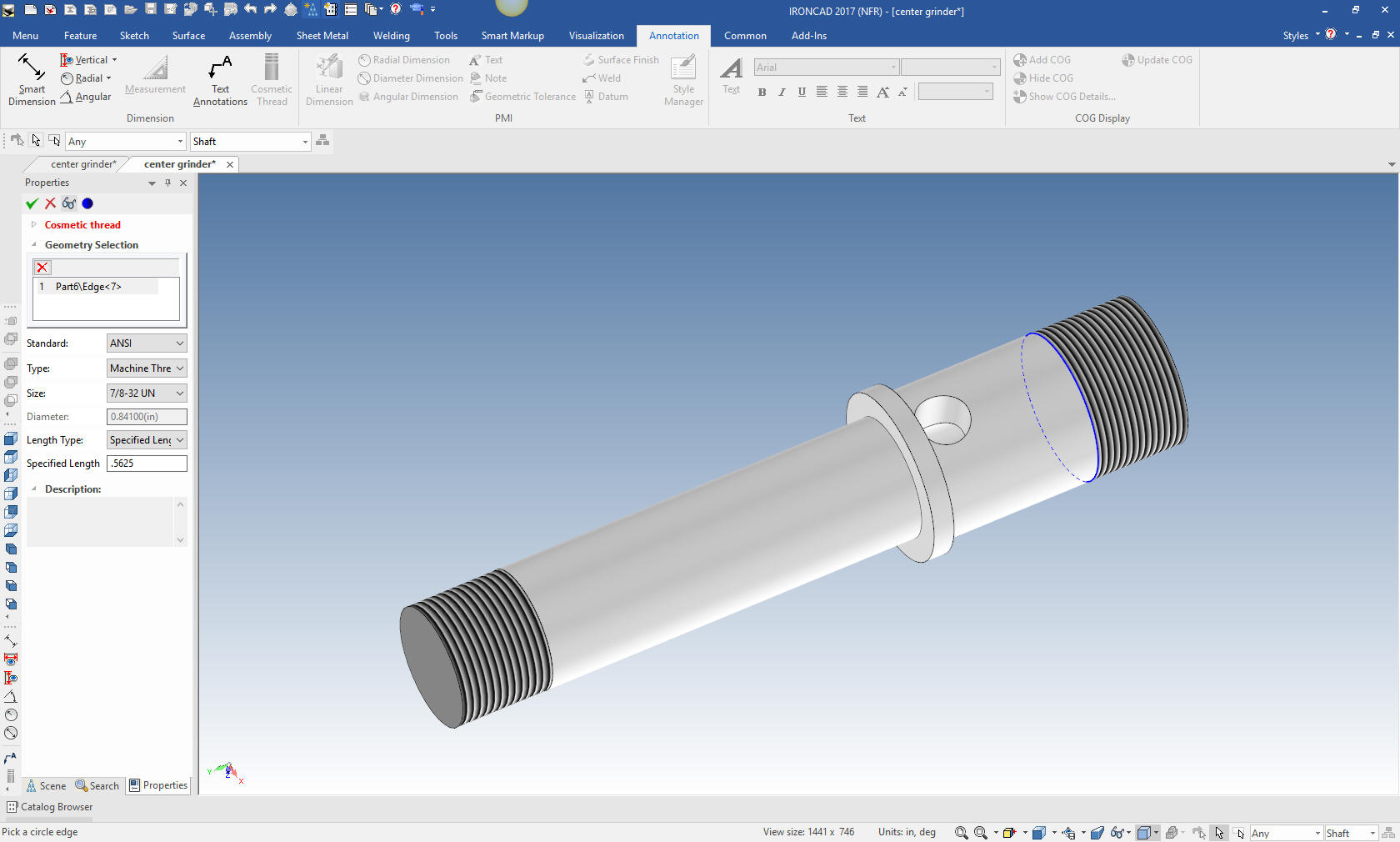

We now create the threads. These are

cosmetic threads and are recognized in the drawing.

We

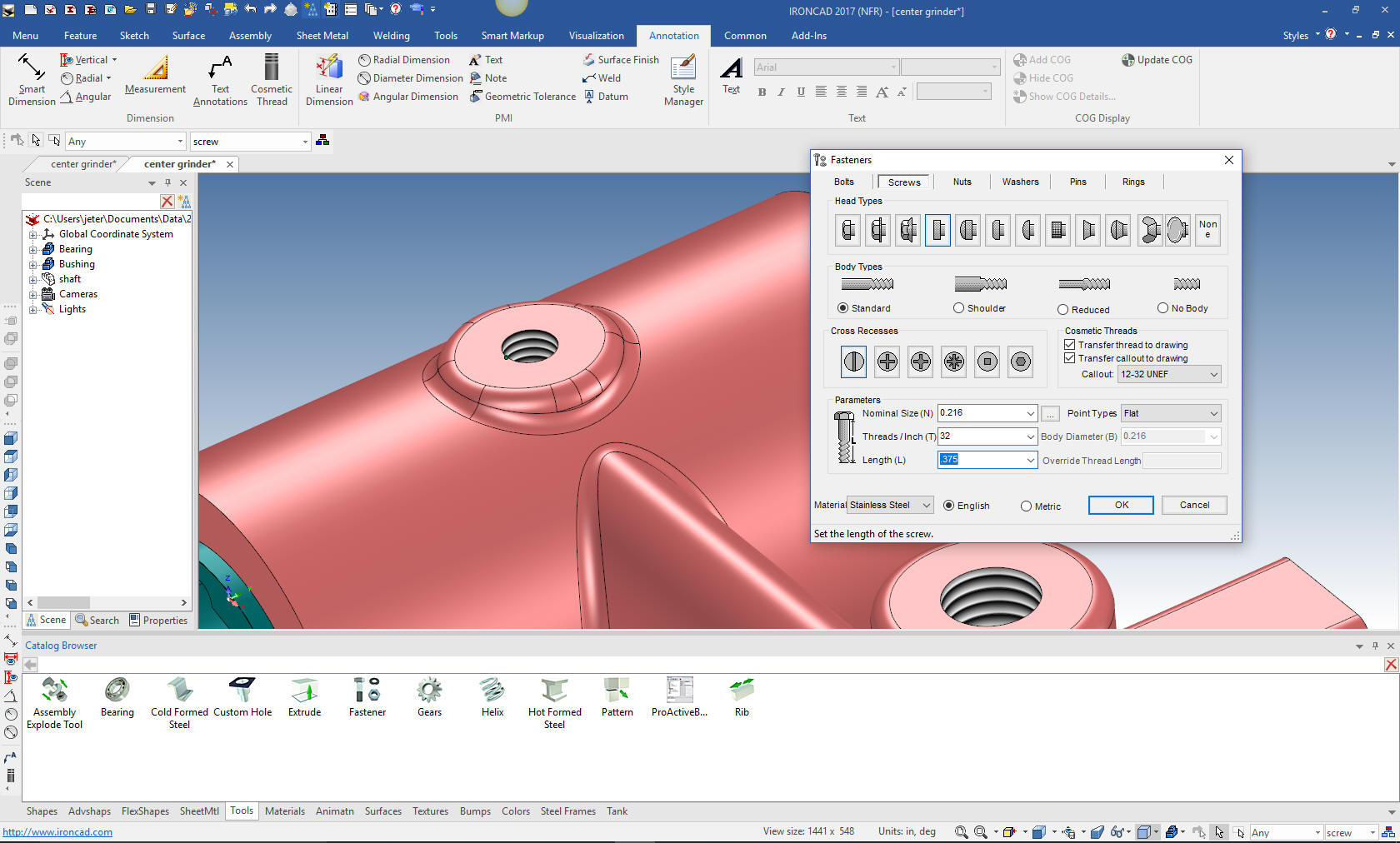

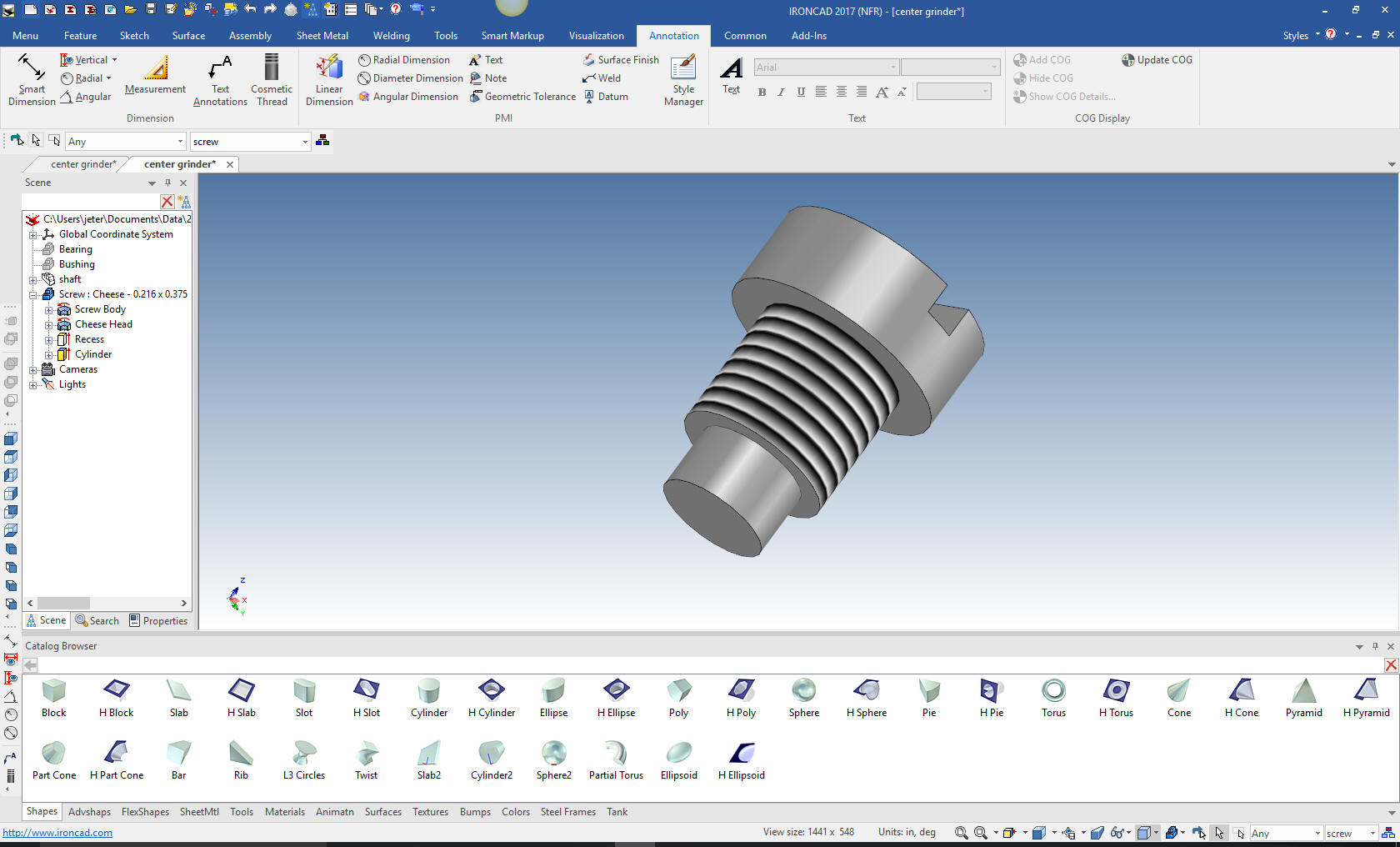

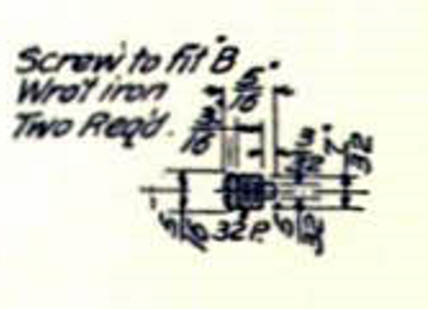

will model the screw. There are two of these screws used. I am

assuming this would serves as a locking device for the bushing and a

lubricating hole.

We will drag an existing fastener from the

tools>fastener catalog onto the location of the screw.

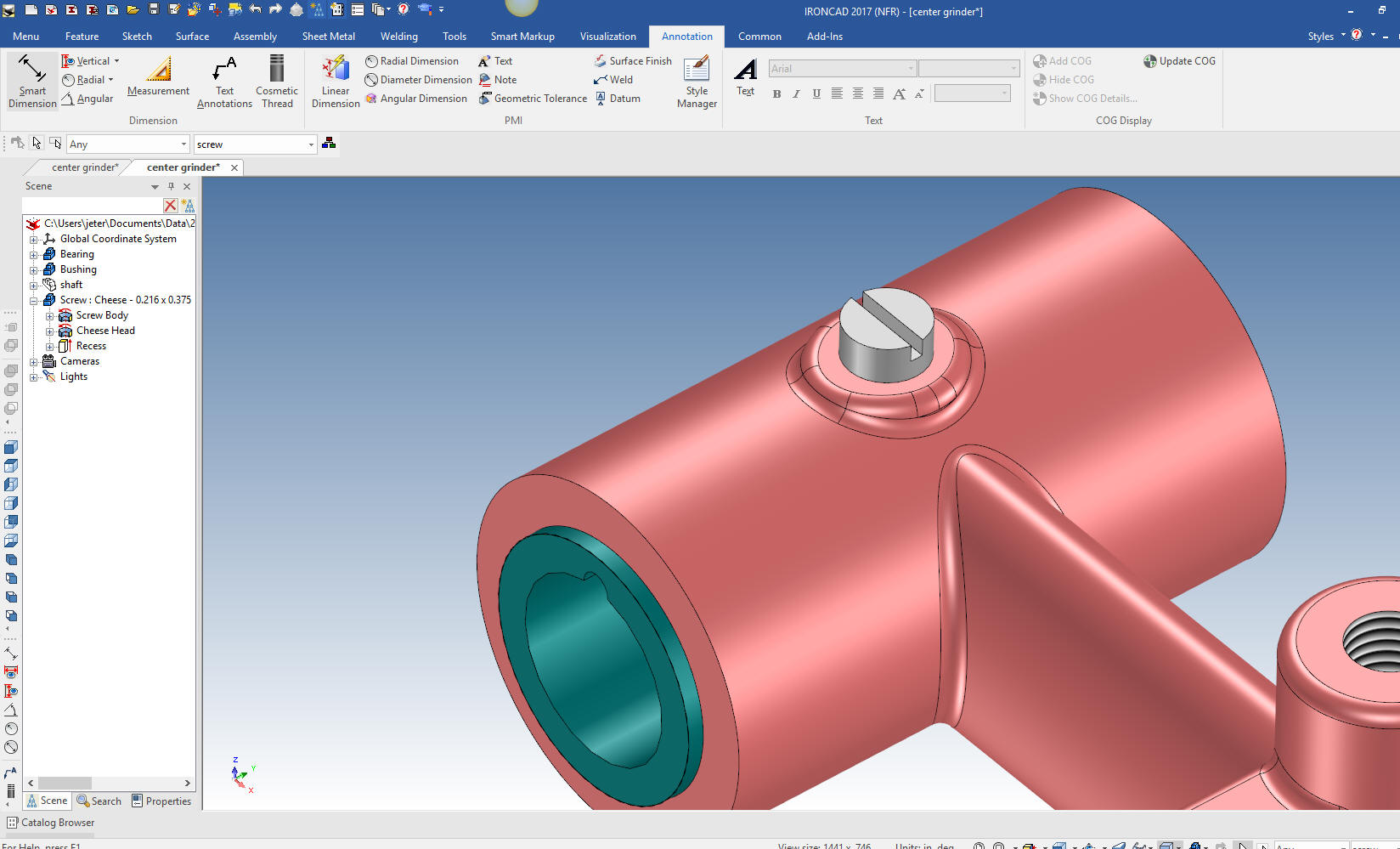

We now

are going to modify the exisiting screw. Like I said I am going to modify

it to meet the requirements I deem necessary. I like doing this as

I discover the problems to show we are not just a canned

presentation.

I hide

the Bushing and Bearing to work on the screw. I will first modify

the head. I will leave it the same height. Notice that the screws is

made up of editable sketches.

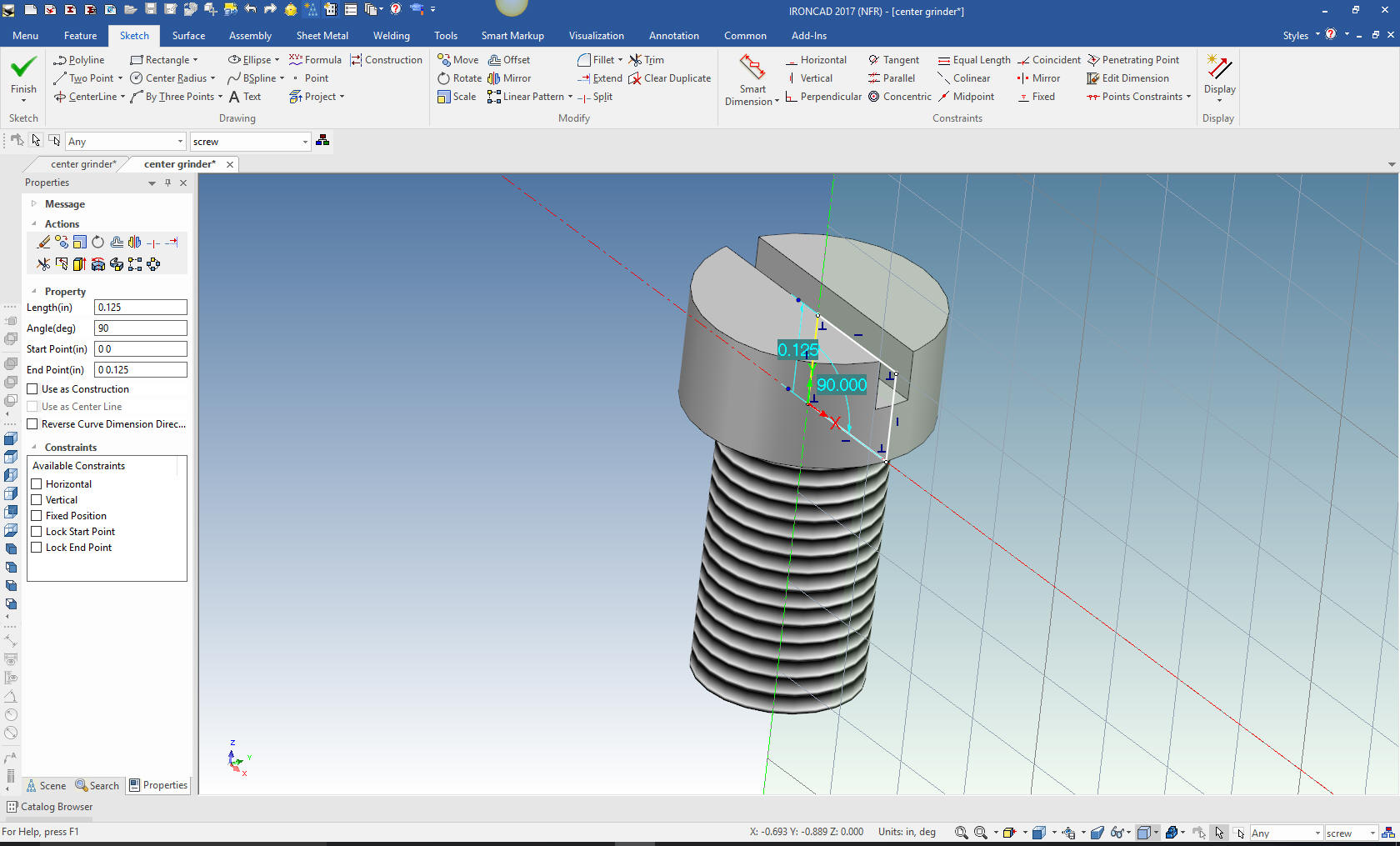

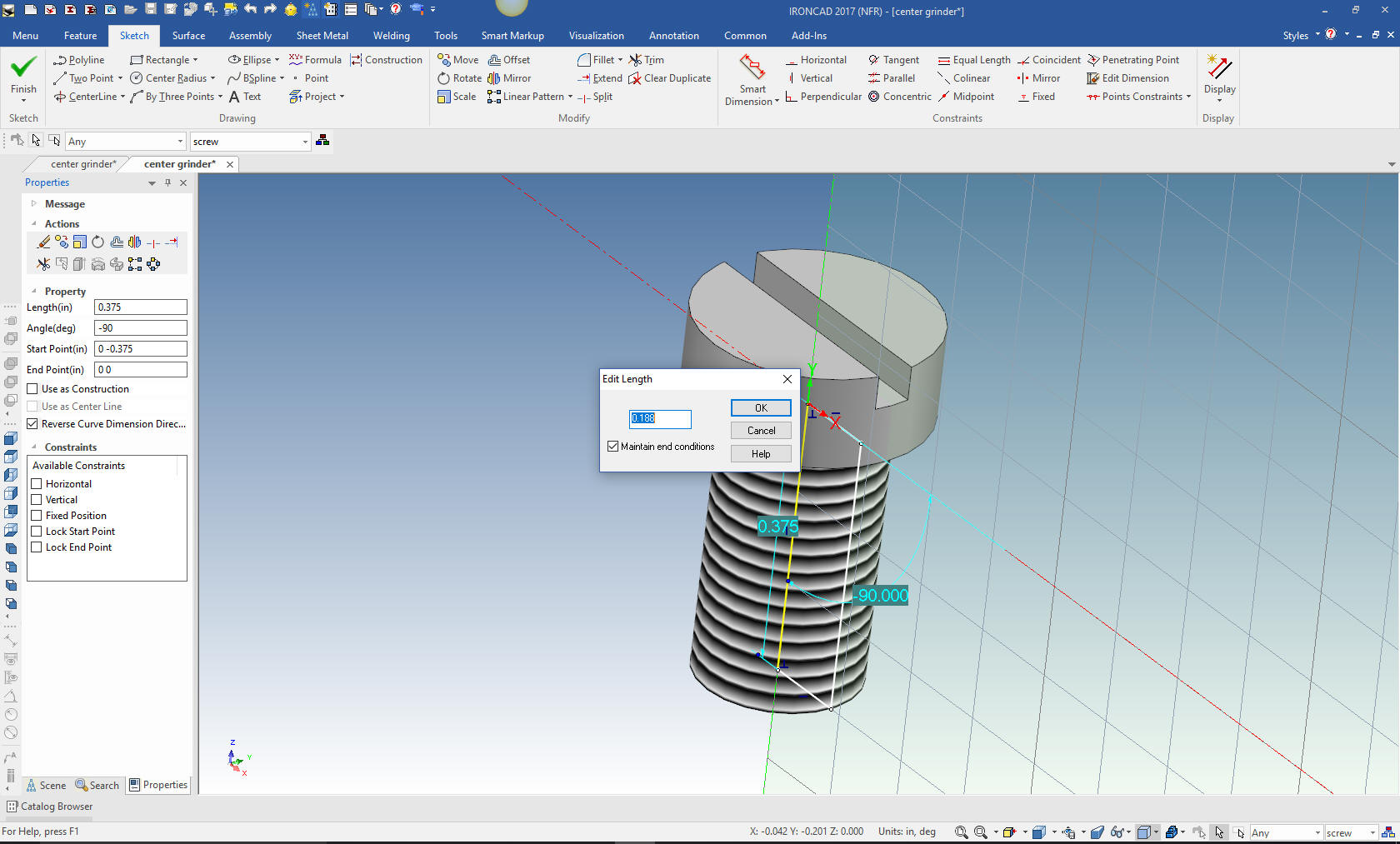

Now we

adjust the body. The fastener creation would only allow me to create

a body the same length as the diameter of the screw so we have to

modify it. Again you can see the sketch that makes up the body. We

set it at 3/16.

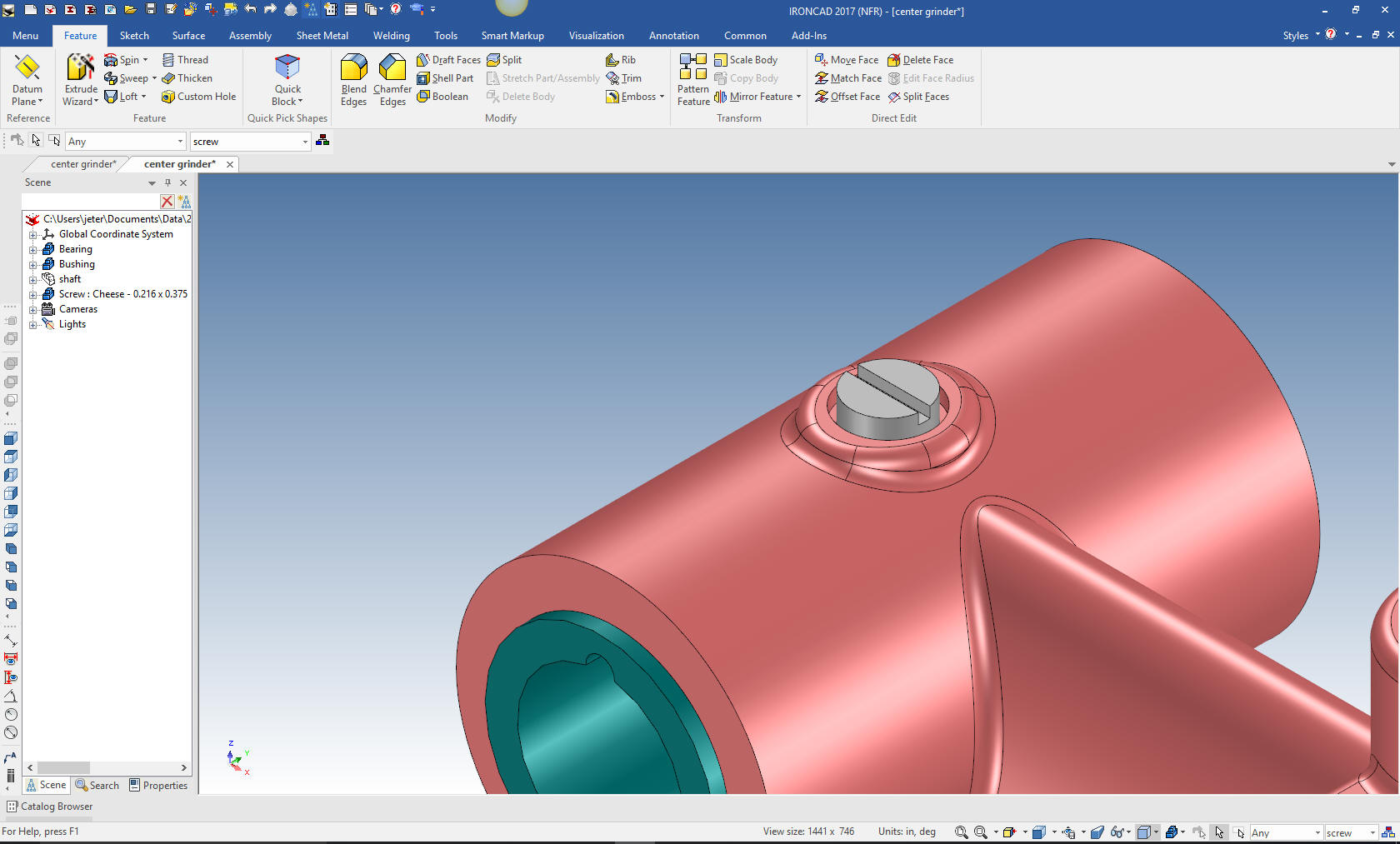

We add

the boss to the screw by dragging and dropping a cylinder to the

center on the bottom of the screw and sizing it. This is used two

places.

Now I

am going to create a counter bore of 1/16 make the screw effective

in locking the bushing. We will size it and move the screw into

place.

We move the screw to set in the counter bore.

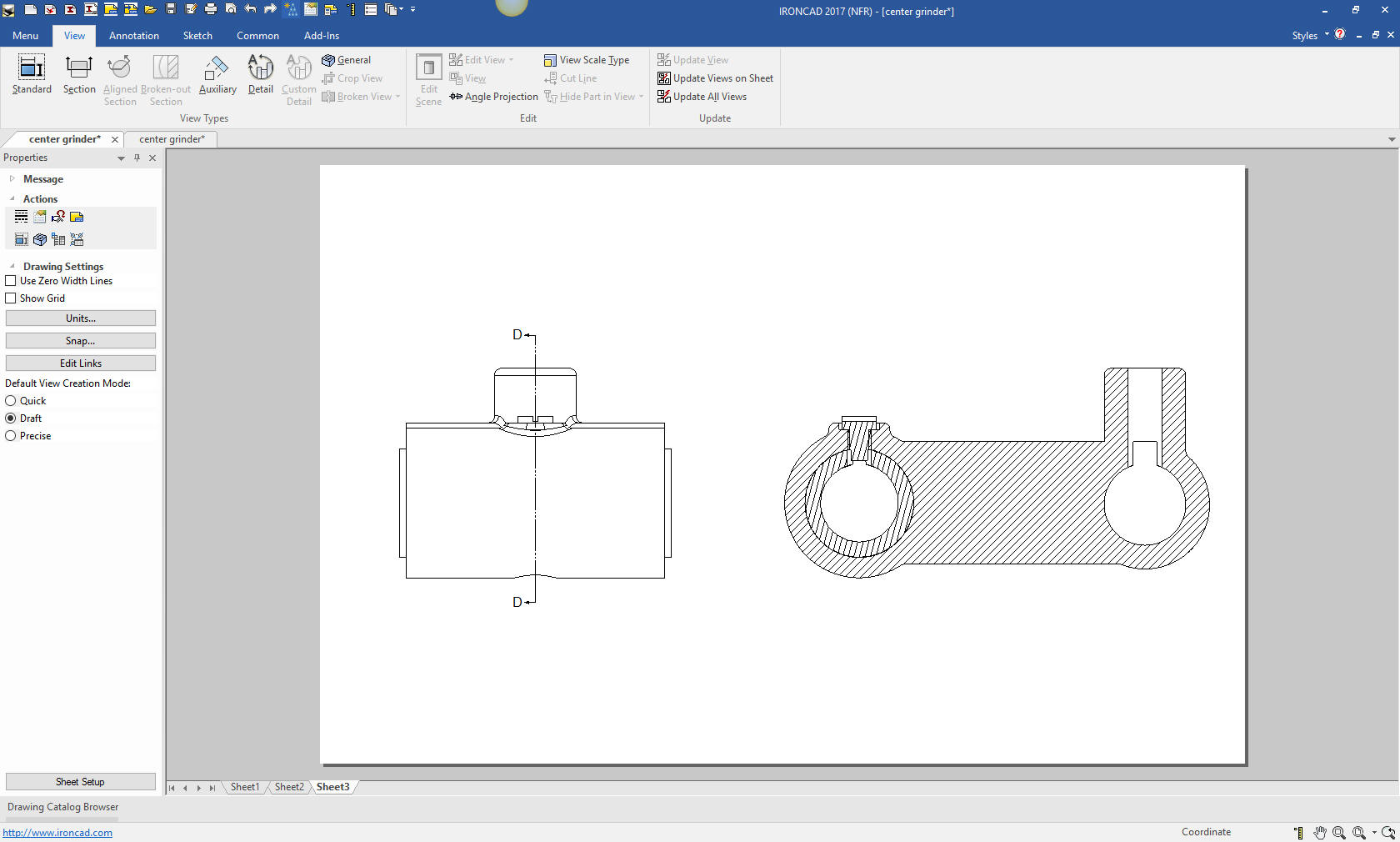

Since we have altered the design a bit, I do a quick section

view to see if there are any problems. You can see the drawing is

just another tab.

Note: I find creating the document and the

views much more clear than doing a section cut in the model. It also

creates a development path for others to have as reference if you

happen leave the job in the middle.

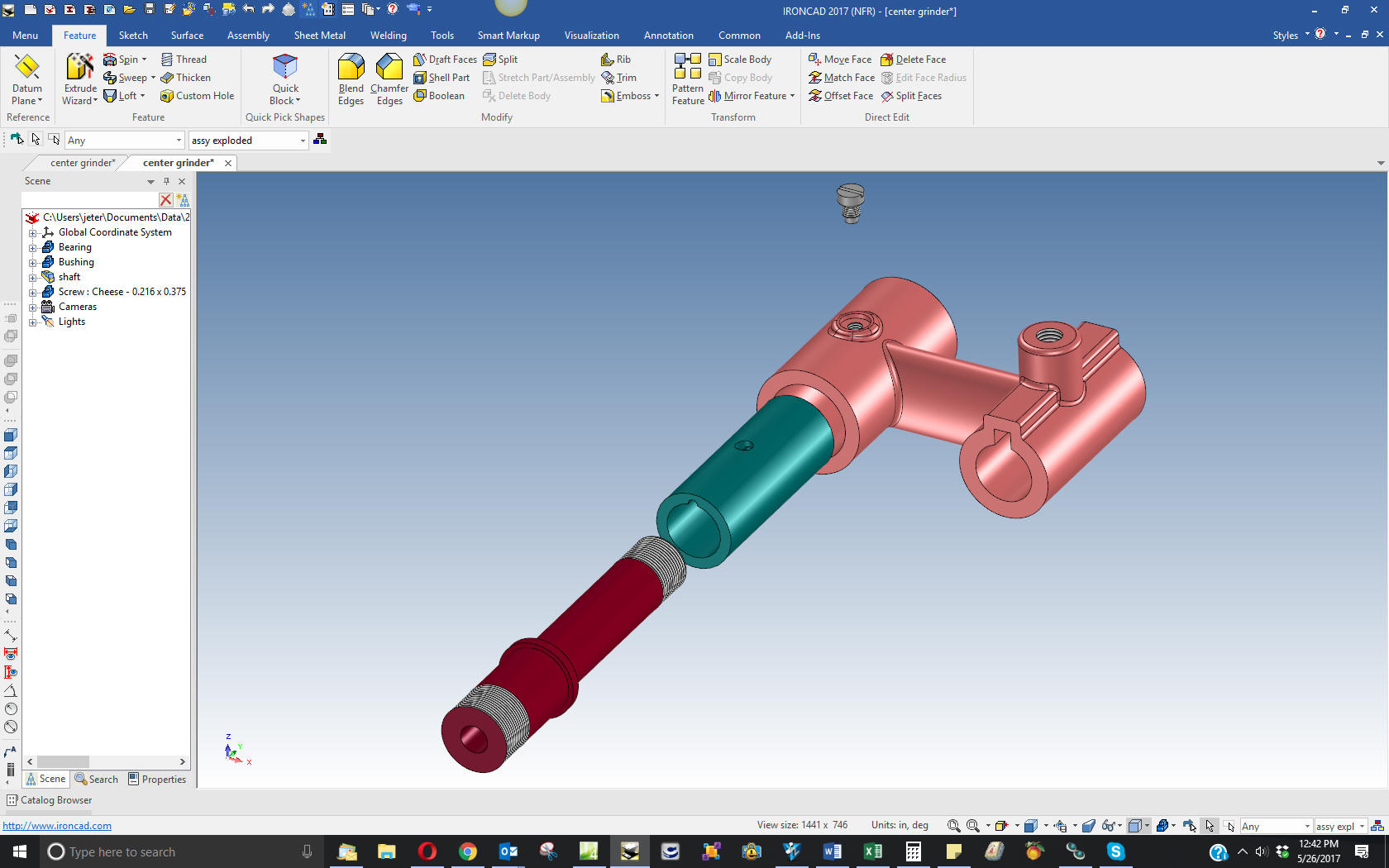

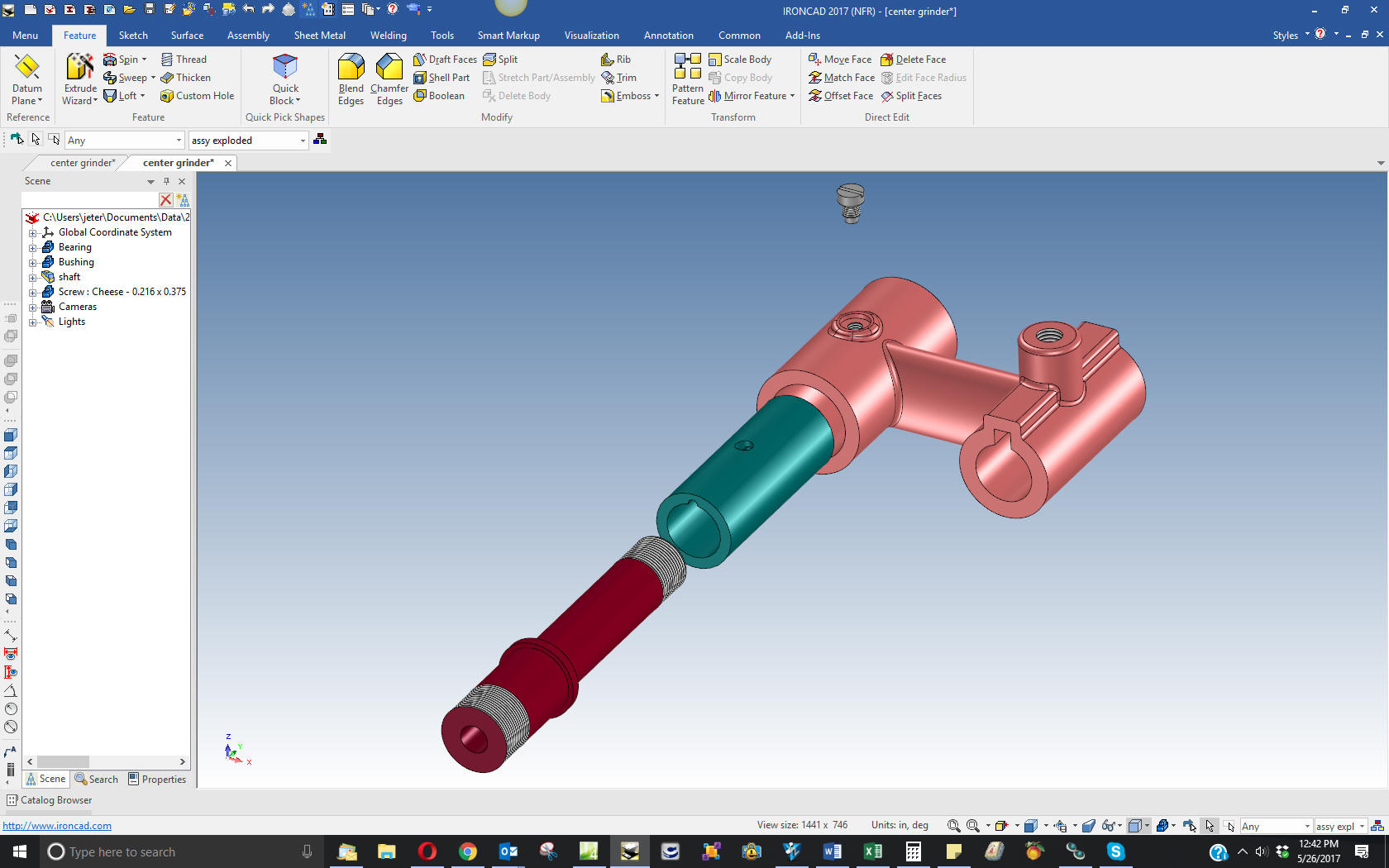

Here

are the parts we did in an exploded view. IronCAD allows you to

create an exploded view that does not affect the original location

of the parts.

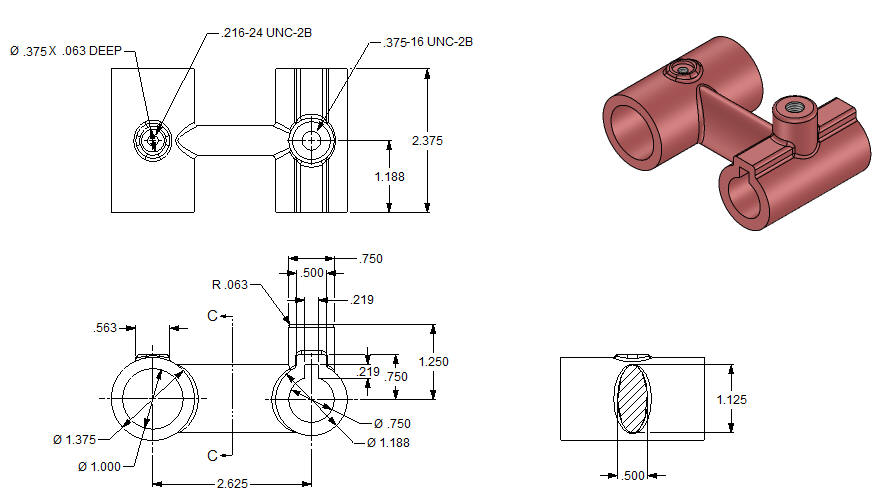

I am

going to detail these parts in one sheet. Ironcad allows all of the

parts to be detailed in one document. Great for one person doing an

assembly.

For

those of you that are creating this parts you can go back to this

article. I have modified the Bushing drawing to reflect the changed

we did here.

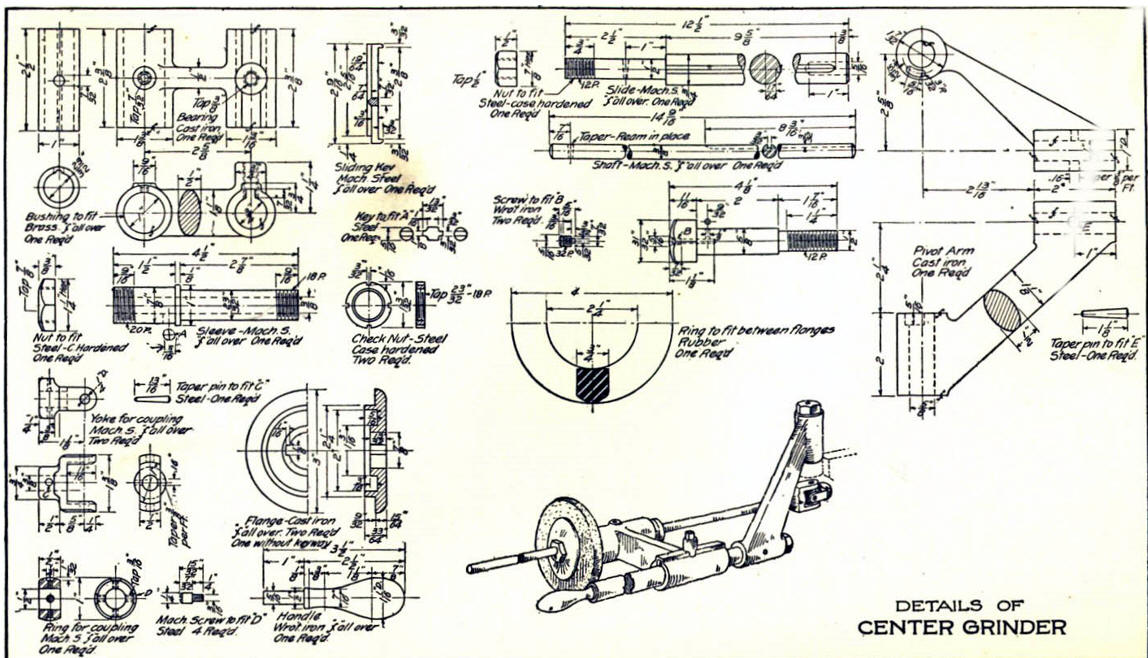

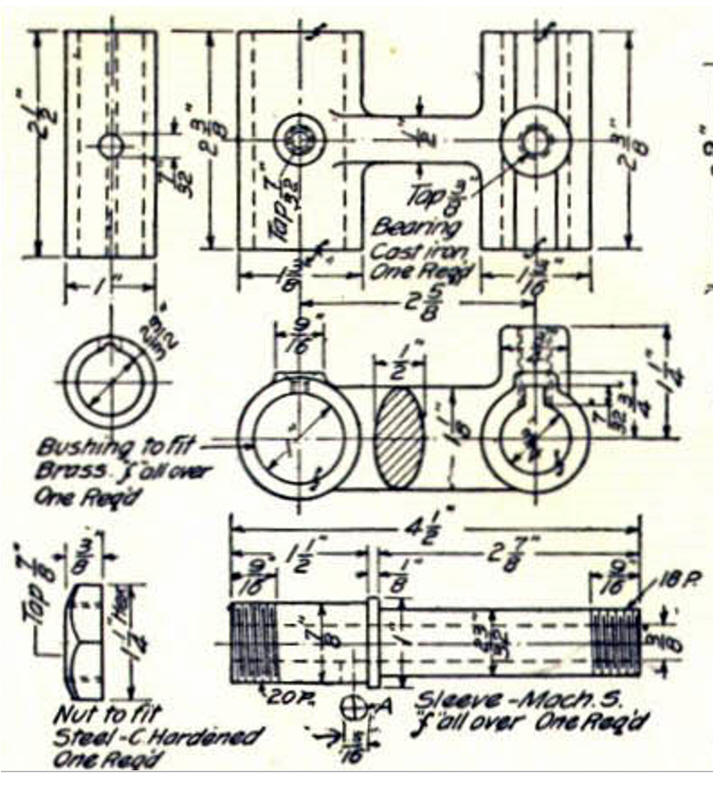

Here

is the original. I did add some dims that were not defined.

I did

modify the screw. You can imagine that this designer was available to

manufacturing to answer any questions.

If you would like

to try IronCAD, please download for a 30 day evaluation.

For more information or to download IronCAD

Give me a call if you have any

questions. I can set up a skype or go to meeting to show this part

or answer any of your questions on the operation of IronCAD. It

truly is the very best conceptual 3D CAD system.

TECH-NET Engineering Services!

We sell and

support IronCAD and ZW3D Products and

provide engineering

services throughout the USA and Canada!

Why TECH-NET Sells IronCAD and ZW3D

If you are interested in adding professional

hybrid modeling capabilities or looking for a new solution to

increase your productivity, take some time to download a fully

functional 30 day evaluation and play with these packages. Feel free

to give me a call if you have any questions or would like an on-line

presentation.

|