|

Zero File or File-Less CAD systems! Debunked!!  |

|

File-less or Zero File CAD Systems Explained I like to keep my finger on the pulse of the

industrial/mechanical engineering industry. Linkedin is full of the latest

information. I was reading one of Oleg Shilovitsky's articles, he is one of the more prolific posters of PLM

information on linkedin I saw this comment from someone we will call “Bob” answering the title question. “.... a file-less data structure is for sure the

future.” Hmm What is a file-less data structure? Here is Olegs answer to Bob's comment! "…. sounds techno propaganda to me. 2020 is in 4 months from now. 95% of CAD systems are file-based. So, what is the point of "file-less data structure"? What does it mean? Exactly my question. "Hi Oleg, could you explain what a non-file based CAD system is? Bob answered back. "Joe Brouwer Oleg would explain better. Onshape

Inc. (founded by same people as solidworks) is the best example.

3DExperience platform with Catia is another good one". I asked "Hi Bob, Onshape has documents. They are stored only on their server in user defined optional folders. They do not have a format that can be saved on a local drive that is why it is not a viable system for serious companies. The way you utilize Onshape documents is exporting to a neutral file such as STEP. Onshape is an incredible document control system which serves, on what you can only call a document bucket, where you can store virtually any file."

Onshape! A View from the Clouds I would like to look at what Catia calls file-less.

But I suppose I would like to know the definition of "file-less" would be. Bob: "Joe Brouwer yes. There are “files” but it’s the expression they have chosen (not me) to use when the hosted data has been more democratized in a way that has more a database characteristic than a file characteristic. As for “serious companies” that’s a interesting perspective probably the same perspective mainframe people said about personal computers. “That’s not for serious computing” So Bob, agreed there are files. What is contained in the "Data Base"? More then likely a reference to files. I am a bit confused what they are reaching for? I am wondering if they aren't considering a system where you put in a "documentation" number up comes the file? Isn't that what they do today? You can read in my Onshape article (I reference above in my comment) why I don't consider it a viable CAD system for serious companies. File-Less or Zero File CAD systems. Again, I have to tell

you many of these folks really don’t think things through before naming

them. Like the “Digital Twin’. If the digital came first,

shouldn’t it be the physical twin? Or Digital Transformation when they are transforming

something that is already digital. Or Industrial Revolution 4.0 when there is nothing new

to drive it except marketing? I could go on, but you get the idea. First the definition. I have laughed many times when someone says, “My favorite definition of”. This is prevalent through the InfoTech world! They redefine many terms. file noun

"a file of correspondence" synonyms:

folder, portfolio, binder, box, document case; filing

cabinet

"do you want to save this file?" synonyms: batch of data, document, text; program "when saving a file, the summary information menu may be displayed" First, there is no such thing as a “File-Less” If you select save, you have saved something! Yes, you saved a file!! He references Onshape. I have been onboard with

Onshape from the beginning. Onshape has documents. I guess they call it

fileless because the files are not accessible locally. Onshape documents are

stored on their servers, no not in the cloud, on physical servers somewhere.

All “Cloud Storage” is on a server somewhere. LOL So, I really have to go no further. There is NO FILE-LESS OR ZERO FILE SYSTEM! We could call these closed systems, which would be much

better. But a closed system would be a huge step backward in interoperability.

Today most CAD systems can read each

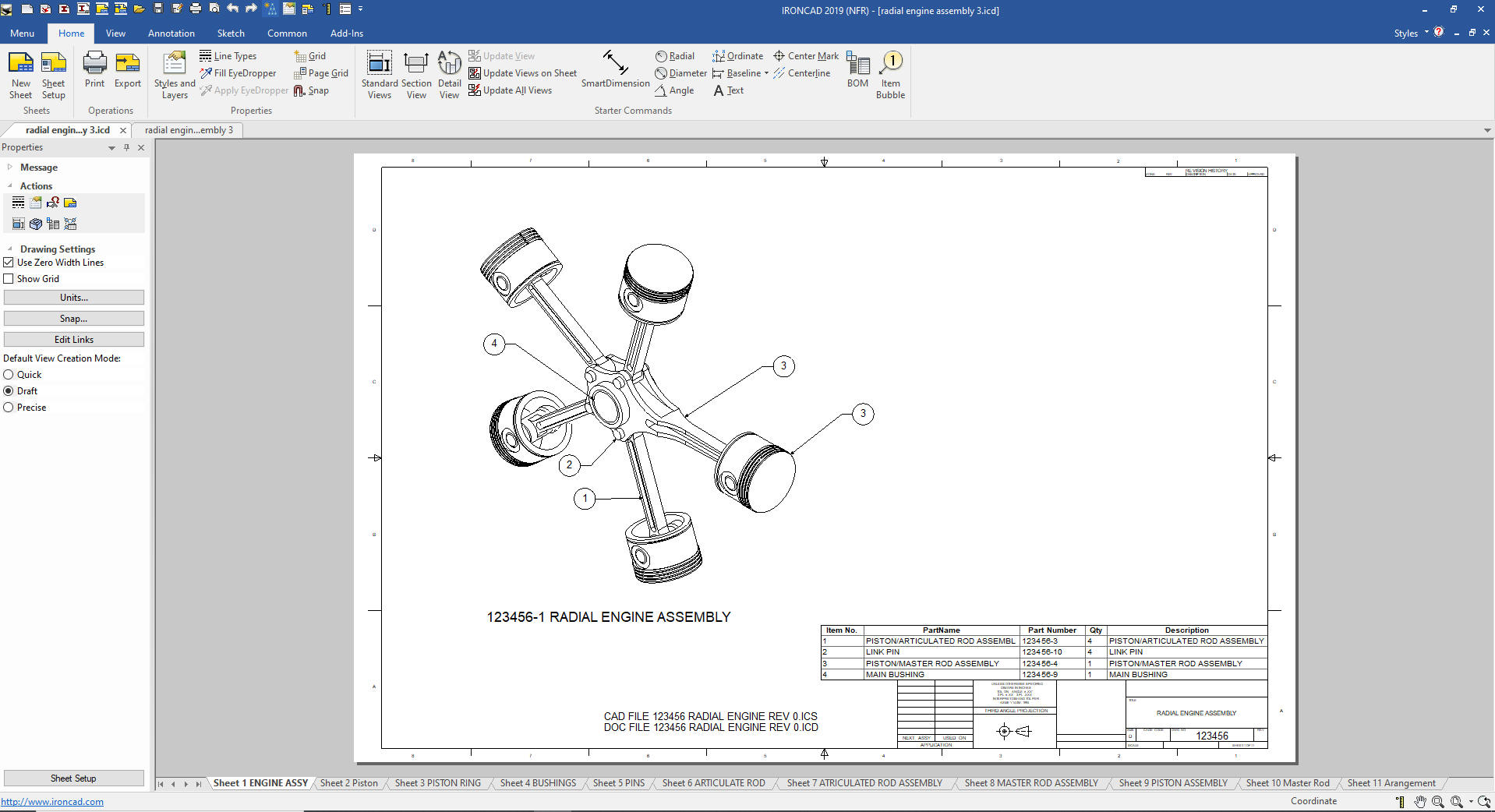

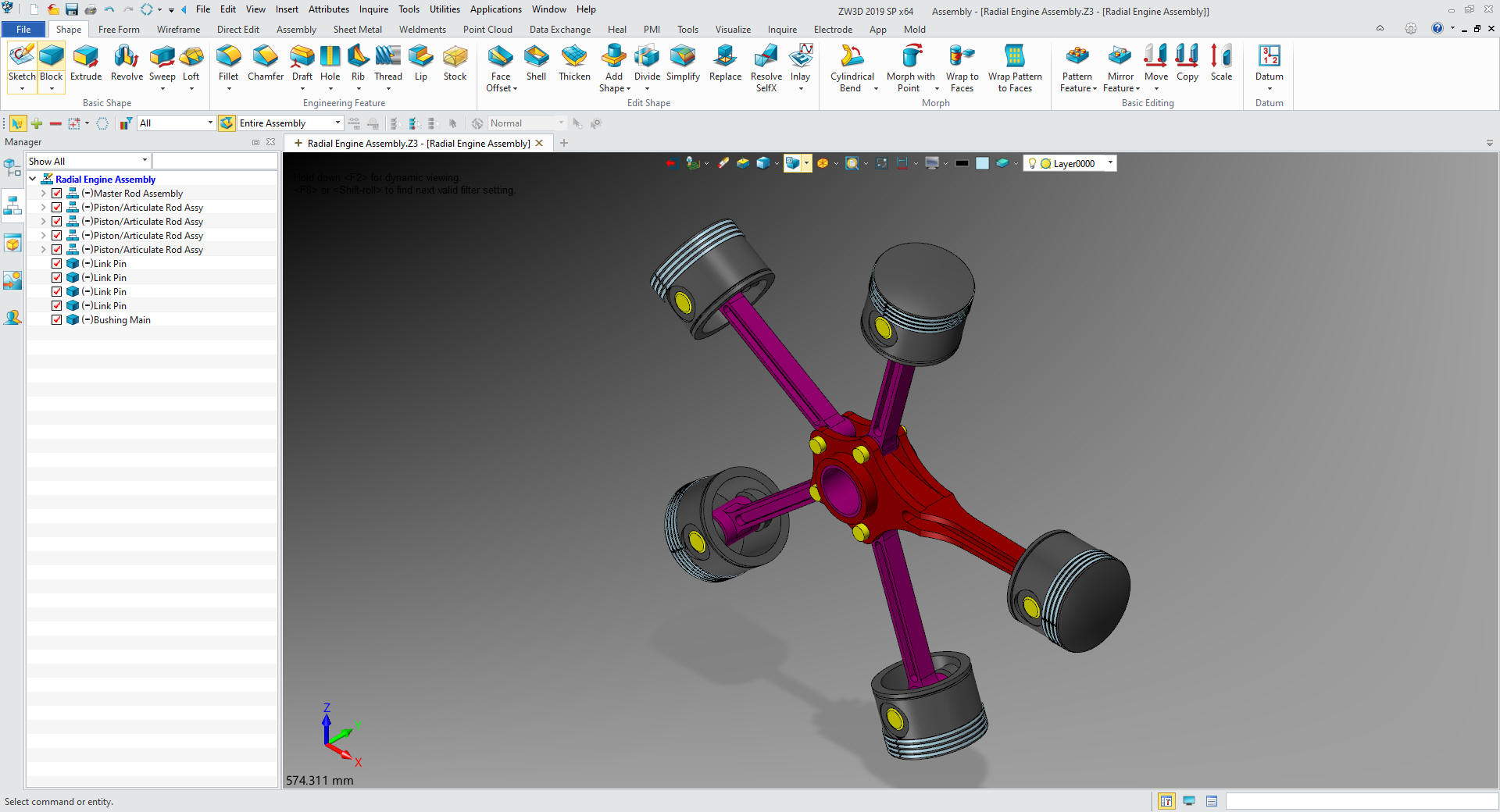

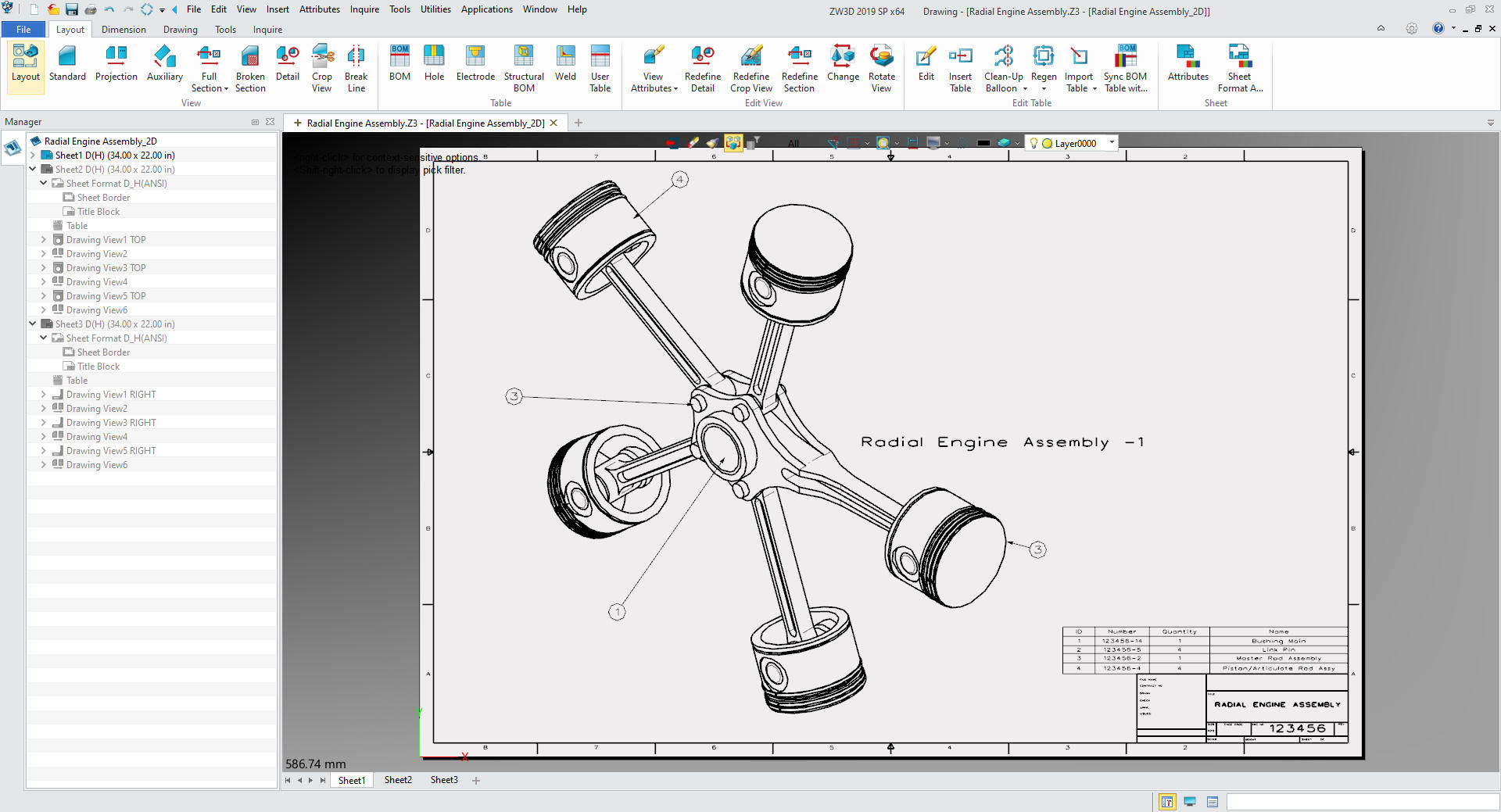

other’s native files. I use IronCAD and ZW3D and I "have" to read the native

files of the major programs in my design/drafting services. You can see some

of my projects here. Using Multiple 3D CAD SyUsing Multiple 3D CAD Systems What we need and I will get into it later is a "Standard Cloud Based Document Control System" outside the CAD system. I am probably the only one proposing it. Why? It is basically free! What they are calling a File-less System. Onshape

I have to admit Onshape offers great access to the

documents, with any browser. Of course, privileges would have to be set up.

But you will never get the native file since it is stored in a special

format on their servers. But you will export or “download” a neutral file

such as STEP, yes the are what we call a dumb file which will require a

direct edit solution.

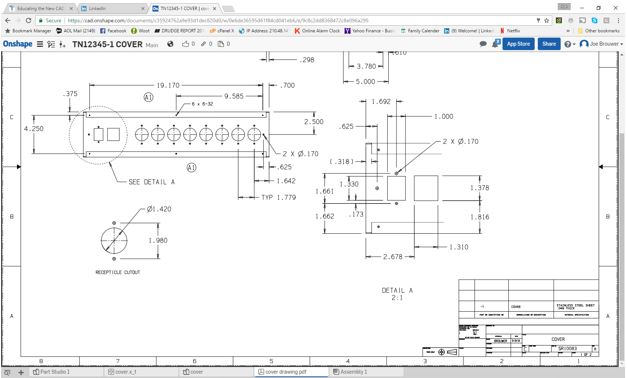

Onshape could not use the PMI system. Boeing only sends out a Catia native PMI file for released engineering. Now, think this one through when Dassault wants to go to Zero Files. What would they deliver? Even a compliant supplier with a seat of Catia would have to have something to export. Hmm so the supplier would have to be tied into the cloud based system? So you type in BAC123456-1, what comes up? So, is this a free Cloud based service where you download a neutral file? STEP? Or load the non-file into your cloud based or locally loaded Catia?? Ah, very clever those Dassault folks you have to have "their' software to play!! A marketing scheme base on the 3DEXPERIENCE? You be the judge. Will Boeing buy it? Hmmm they were smart enough not to buy Catia 6 (released 10 years ago). I expect Boeing will tell Dassault they are happy with the marginal but somewhat stable Catia 5! You can see below Onshape has individual documents, each one are in a constant state of creation and are automatically saved when you exit the part or assembly, so they are “FILES” .Here is the part document

Here is the AID

So Onshape is hardly files-less Here is an article I found!

Are Zero File CAD/CAM Systems the Future? I left a comment. Sadly,

most of my comments are deleted. It seems like many of these people only

want comments that agree with them. Of course, Oleg, chimed in. This whole

industry seems like it is made up of a mutual admiration society. "I am a bit

confused. What are these files? I assume they are documents and engineering

has not eliminated documentation.

Engineering's only product is making available concise, complete and

unambiguous documentation to manufacturing. There are 3

forms of approved documents that you deliver to "outside" suppliers, Inside

manufacturing can work off a napkin 1. Drawing

So, explain what you mean by zero file?

I have always worked in a single model

environment. Starting with

CADKEY in the mid-1980s. The 1980's - 3D CAD - The Beginning Then with

IronCAD in the late 1990s and then ZW3D with its multi-object environment.

The Single Model Environment - Zero Files?

Now a single model environment has many parts

and AIDs inside that are not files in the single file. You could call this a

somewhat Zero File environment.

None of the parts are

saved individually inside the file. They are saved when the single file is

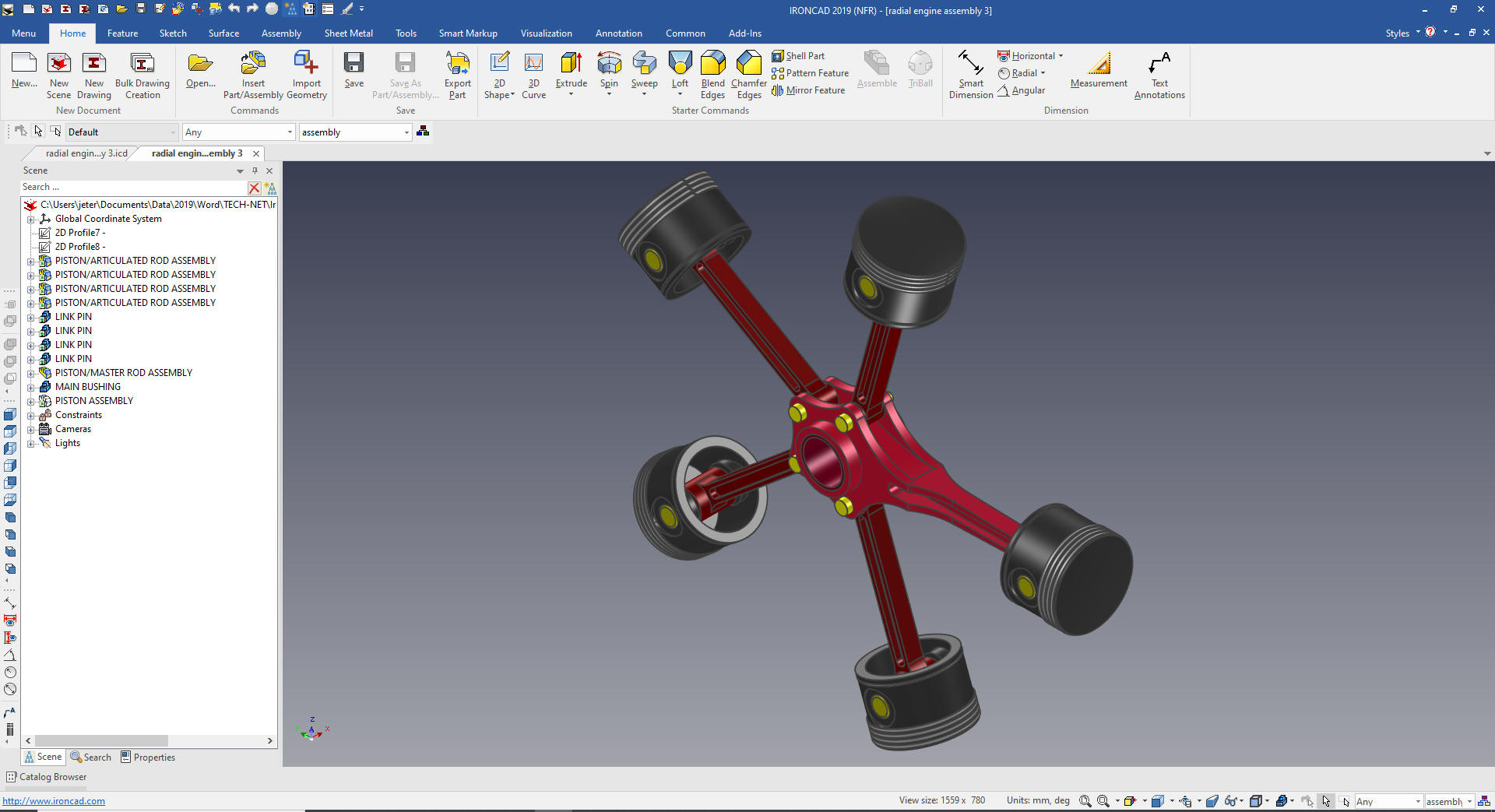

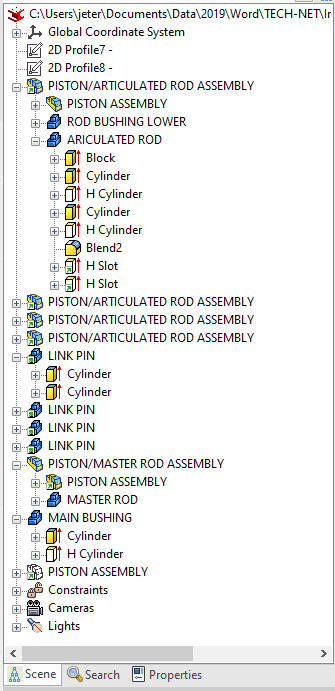

saved. Here is an assembly in IronCAD in a single file. Now any of these parts or sub-assemblies can be saved separately in its own file. You can design like the Solidworks clones with separate parts. Take a look at the comparison with the original Catia assembly. Two files as compared to 30! IRONCAD vs CATIA Lesson 3 Assy

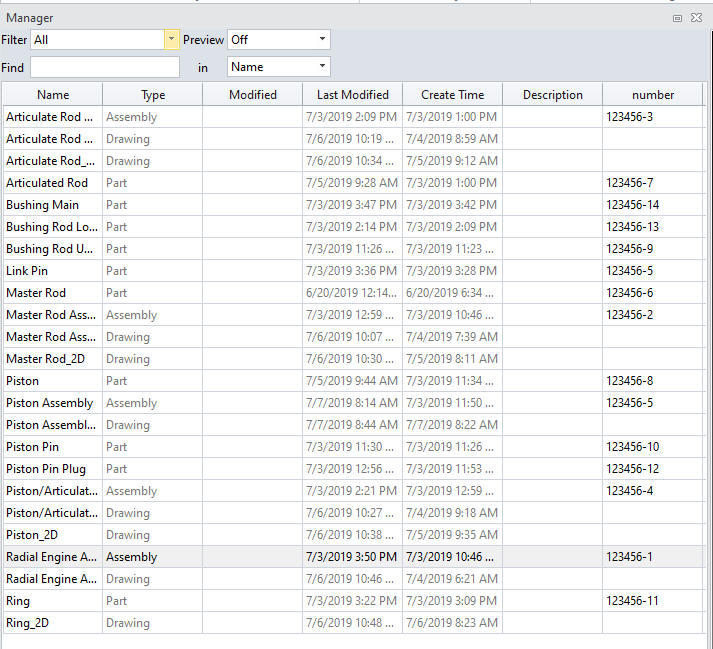

Since ZW3D AIDs are integrated they are tied

directly to the parts, so at any time I could make these part external. This

overall manager shows all of the parts, assemblies and AIDs in this "FILE".

There are a couple of other CAD systems that have the part, assembly and AIDs in the same files, but ZW3D is the only history/direct edit system the others are direct edit only. I feel without history you only have half the design capability, especially for conceptual design. What bothers me most is those that don't do any CAD work, write about these subjects. They hear the latest buzz words and don't even do an investigation. Those the are trying to solve the problem are not intimately involved with the basic CAD process of designing parts and assemblies. Remember Zero Files is a Dassault concept, today! Not a functional feature! A promise to solve all your problems, so is now the Catia 6 solution a failure? It was to solve all the PLM problems! Another huge problem is with PMI. Boeing and all airplane design companies send out a native Catia PMI file as the released engineering. There are third party programs that can read the Catia native PMI file, like ZW3D. A zero file could only send out a neutral file like a STEP, a dumb file. For native (files) everyone would have to be onboard. Ha ha, the plan becomes clear. Dassault wants to sell a special version of Enovia!!! At least Onshape offers free access!! Dassault offers nothing free! I think they are the only system that charges for a viewer! If you think it is complex, time consuming and expensive now, just wait for "Zero Files" Here is another article. The Power of ZERO: 3 Questions and Answers Now that you know the concept is debunked you can see all the holes in the article. This is by Dassault, of course, they would love a closed system to increase the of their users on the software. The goal of the 3DEXPERIENCE is to create more user dependency. I believe we should break this hold. We can and for virtually very little cost. I know personally Dassault is responsible for keeping Boeing one of the most ignorant and isolated manufacturing companies. Their lack of interoperability is beyond belief. CADKEY or Catia? Boeing’s Billion-Dollar 3D CAD Mistake! I assume this is the same for the rest of the aircraft manufactures basing their engineering on Catia 5. Even they are not foolish enough to go to Catia 6 or the "3DEXPERIENCE". The Worst to Best 3D MCAD Systems Expanded! GE's Jeff Erno sharing his thoughts on the Power of Zero with ENOVIA The problem the engineer is describing is the basic nature of the Pro/e paradigm of separate parts, associative assemblies and AIDs. They are trying to move out of a limited system by adding more limitation. They talk like there is going to be a new solution to solve the problems they have created. How do you solve the fellows in the videos problem is less associativity with external document control. One of the problems we have is how do we archive Pro/e type associative assemblies? We have to put them into a format where there are no associations. I would say a "packing" process. But you would have to go to an external archive that is maintained by a document control group outside the CAD system. I suggest the companies look for a solution outside the CAD system, utilizing the CAD system to provide only the model and any associated information documentation in an external archive that can be easily accessed. I envision an Onshape like "Cloud Based Document Control System. This solution would cost nothing just change the process. We would need to develop the browser accessible Cloud Based system. The model is already there! The CAD system is a dismal failure for managing Engineering with their PLM and PDM solution, so much so there are hundreds of third party solutions and they don't deliver what's promised. Their biggest blame for failure is the lack of employee participation. That should say it all about the user friendliness of their products. PLM had no chance of success, because it cannot be standardized. Why? Because CAD cannot be standardized with 5 major CAD systems all trying to keep their users in the fold by delivering unique non-interoperatable solutions. Here is a fellow showing that PLM now needs to be standardized. I was beating this drum over a decade ago. I have debated with these folks over the years. The sad thing is that they are in the mindset "If it wasn't thought of here, it wasn't thought of". PLM and the need for standards Here is my article showing the PLM will fail because it "can't" be standardized. The Death of PLM The MBE/MBD/PMI process has created a complete world of workarounds! Standard Cloud Based Engineering Document Control Standard Cloud Based Engineering Document Control Part II The Embedded Title Block! A PLM Solution! Here is a horror show of one of their solutions; MBE (Model Base Enterprise) and its ugly step child the PMI (Product Manufacturing Information). I can tell you the people that are trying to solve these problems do not work in the area where the problems exist! Why MBE/MBD/PMI Will FAIL Why MBE/MBD/PMI Will FAIL Part II I suggest all of the major CAD companies, InfoTechs and PLM gurus to study the standard document control system of the past based on drawings. Remember you had part and sub-assembly drawings that could easily be accessed and follow to the single drawings that needed to be scrutinized. I worked on the board for 17 years and could find the drawing and modify it before the poor GE Power Engineer could find it in multimillion dollar CAD system. My First 17 Years or "How did we do it without 3D CAD!" Engineering Documentation - A Primer for the PLM Guru! Conclusion PTC, Siemens, Autodesk or Dassault haven't delivered a workable solution for over 30 years, what in the world makes you think they will deliver a viable solution tomorrow? The definition of insanity is repeating the same actions over and over again and expecting different results. It is time for the industrial/mechanical manufacturing industry along with academia to form a group to look into how engineering got to this level without the vested interests of the major CAD companies. They can start with many of my articles. Of course, I am a draftsman! The millennial's today do not even have a clue that drafting was in charge of all the engineering documentation. It is time for all to realize:

"Engineering's only product is to make available Nothing gets made without the documentation!

|

TECH-NET ASSOCIATES | RENDERING OF THE MONTH | CAD•CAM SERVICES

HARDWARE | TECH TIPS | EMPLOYMENT | CONTACT

The

scene b

The

scene b