The modeling technique is

hugely responsible for the level of productivity. Those of you that

are only trained in the constrained sketching world of the major CAD

systems

are truly limited by not using the freedom of Streamlined Sketching

and Feature Based Design,

that is available in even the most Pro/e-ish of CAD systems. If you

or your

designers are designing in these very unproductive and time

consuming processes it might be time to review your standard design

processes. Don't have any do you?

These

lessons started out as

product comparisons, but quickly turned into a study in 3D modeling

techniques.

Ironcad USA Webinars

When I introduce IronCAD's very

flexible design paradigm I have a hard time to get the Pro/e clone

users, like Solidworks and other programs to understand the drag and

drop design paradigm.

Download

IronCAD/Inovate and take

the one day and 17 lesson course. I get rave reviews from my new

customers. Give it a try, this is a fully functional 30 day

evaluation with all of the native translators so you have access to

your legacy engineering information.

IronCAD Self-Pace Training Course

I saw the

following Solid Edge YouTube tutorial and thought I would give it a

try on IronCAD. I have to tell you it is almost tortuous to watch

the Solid Edge presenter. I

have tried to do top down design in Solidworks and failed. Inventor

is a bit better but all of these programs including Solid Edge create

external parts. You will see a huge difference in IronCAD's true

single model environment.

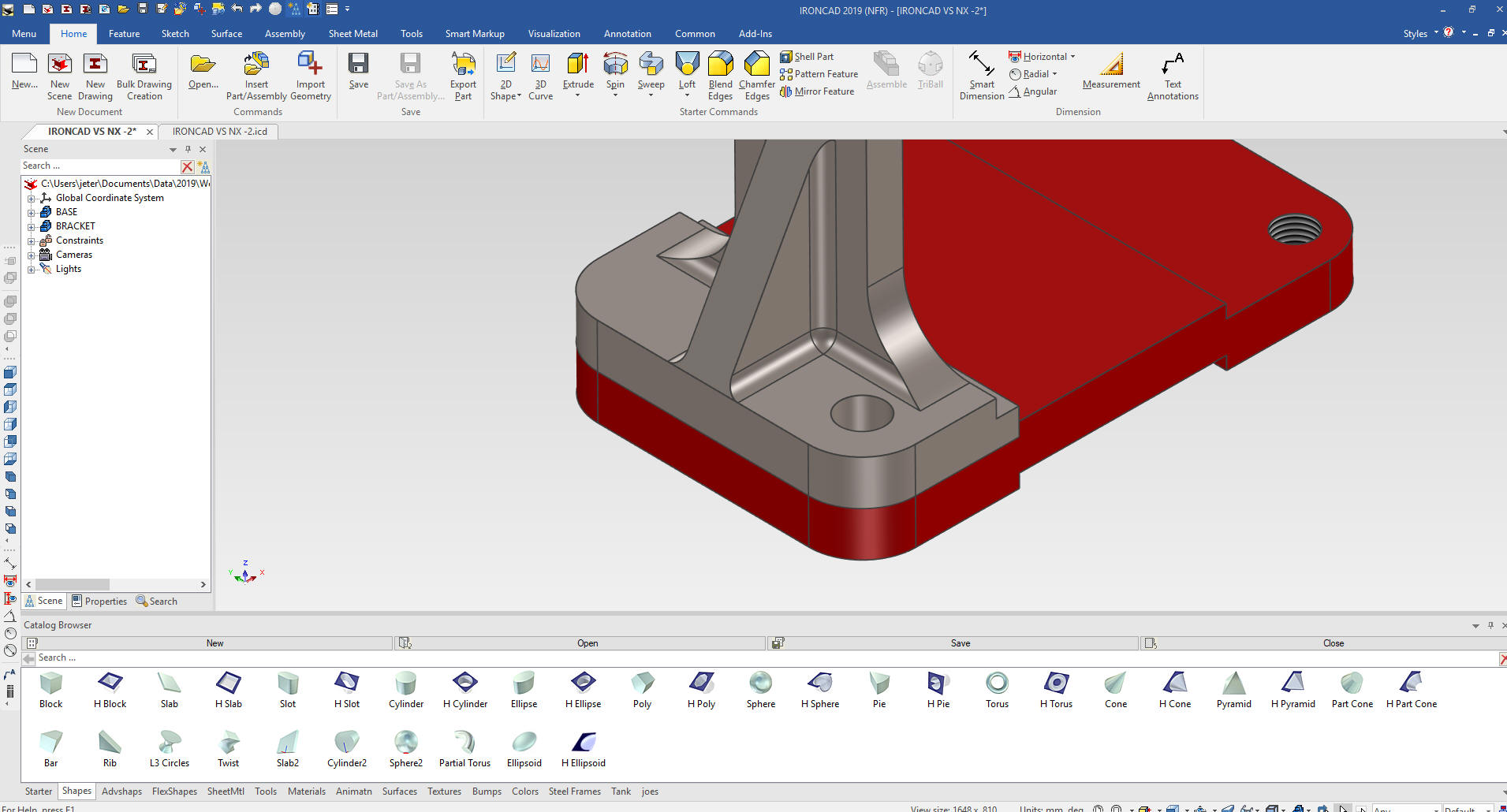

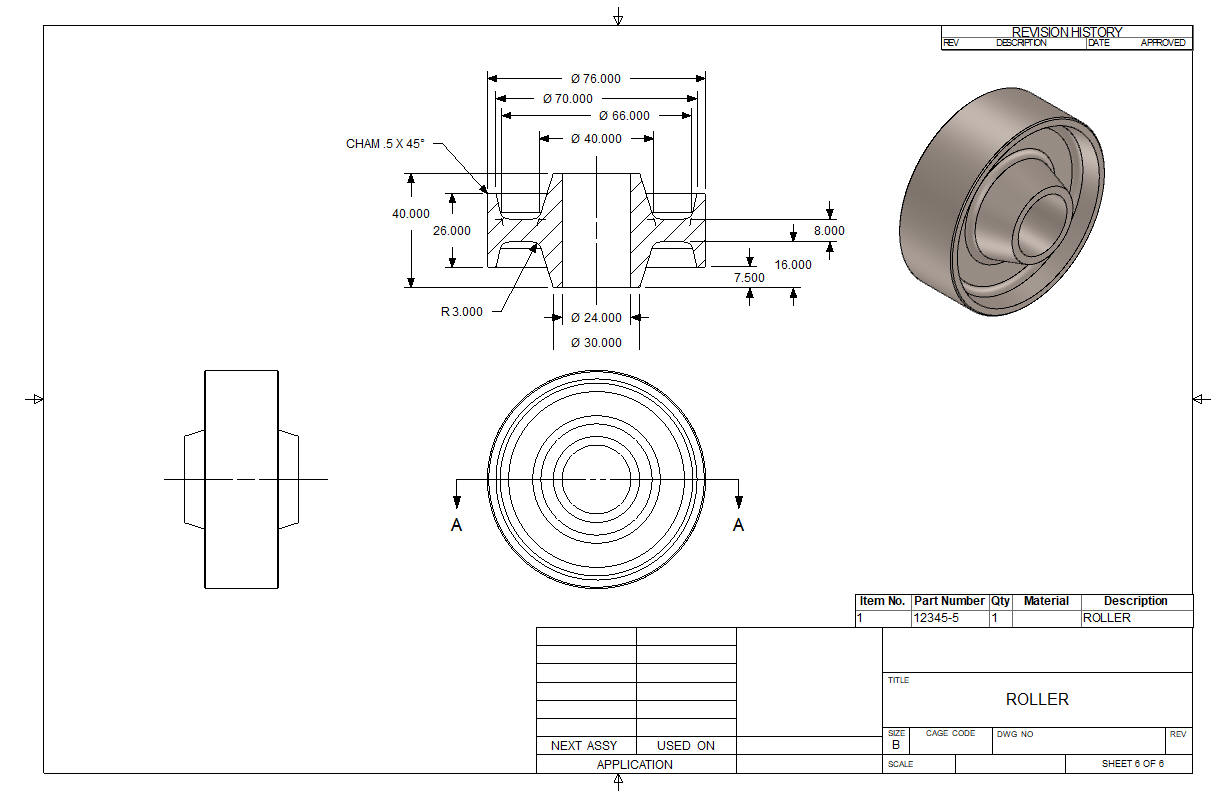

You can see the same basic part

done on NX. The part is dimensioned incorrect in the Solid Edge

drawing.

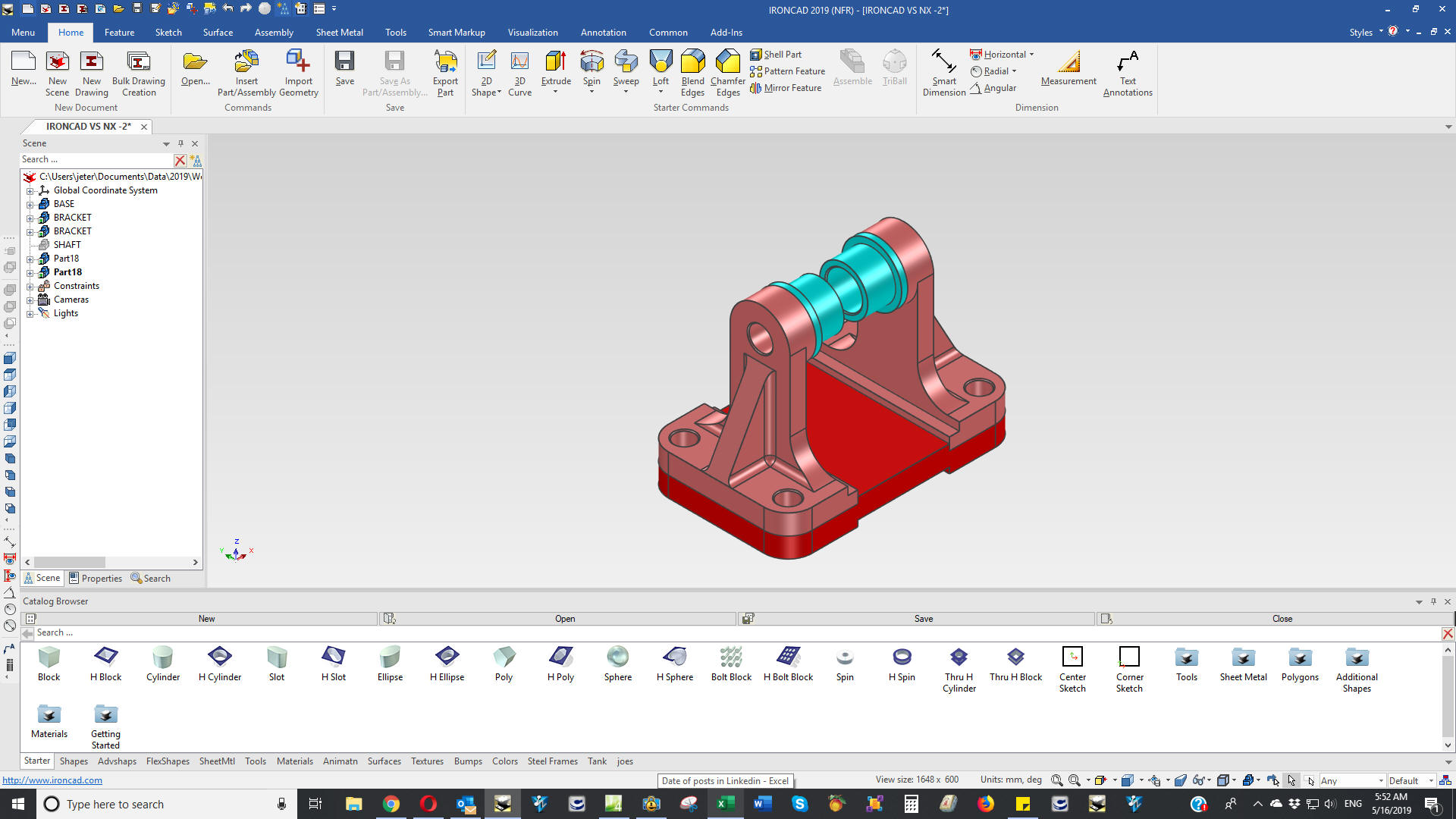

IRONCAD vs NX

Solid Edge is a constrained sketched based

system as are Fusion 360, Solidworks and Creo. In the following

lessons you can see that this modeling paradigm is use throughout

the industry causing millions of wasted hours.

3D Modeling Techniques Defined

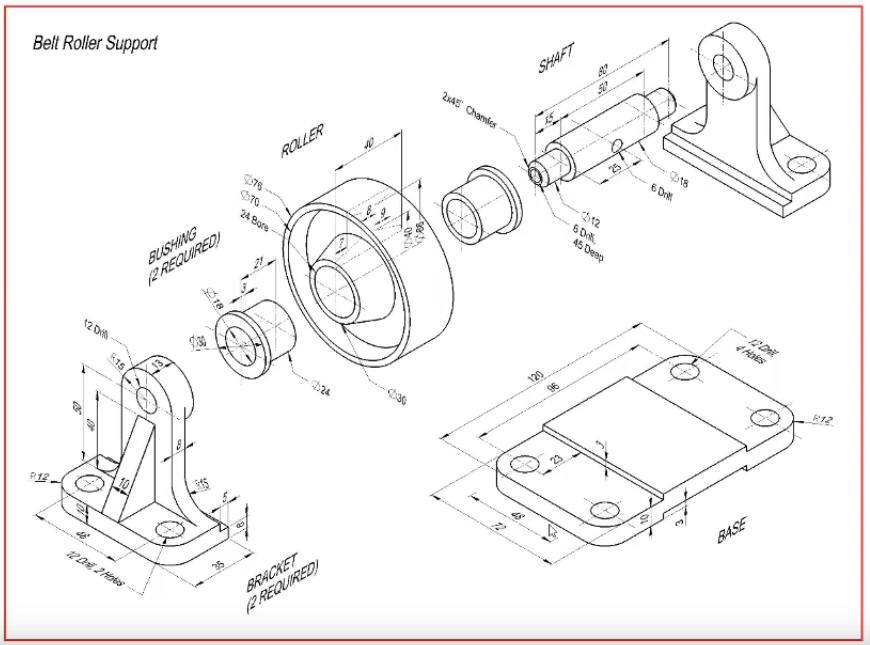

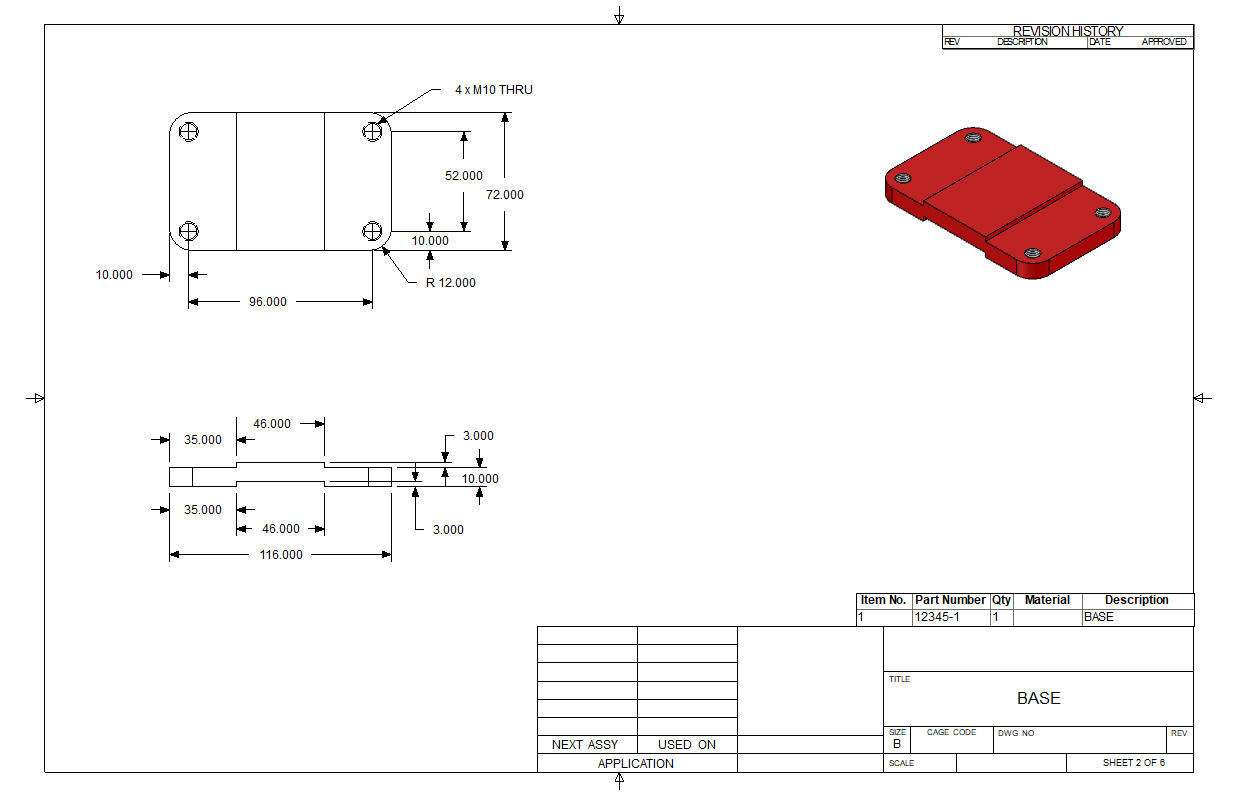

Here is the Isometric drawing. It is incorrect. So use the drawings

at the end for a good assembly. The top boss on the base should be

46mm.

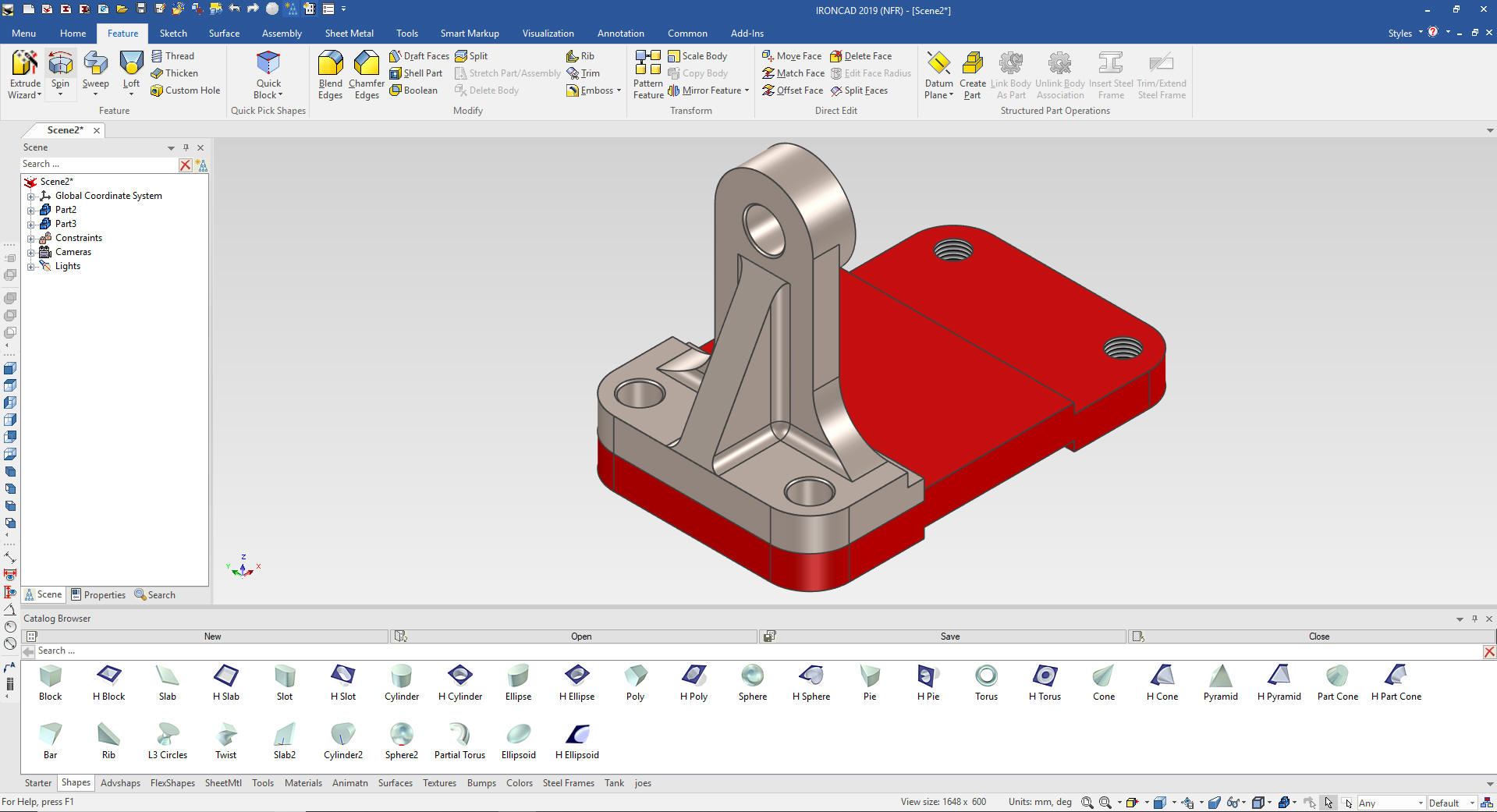

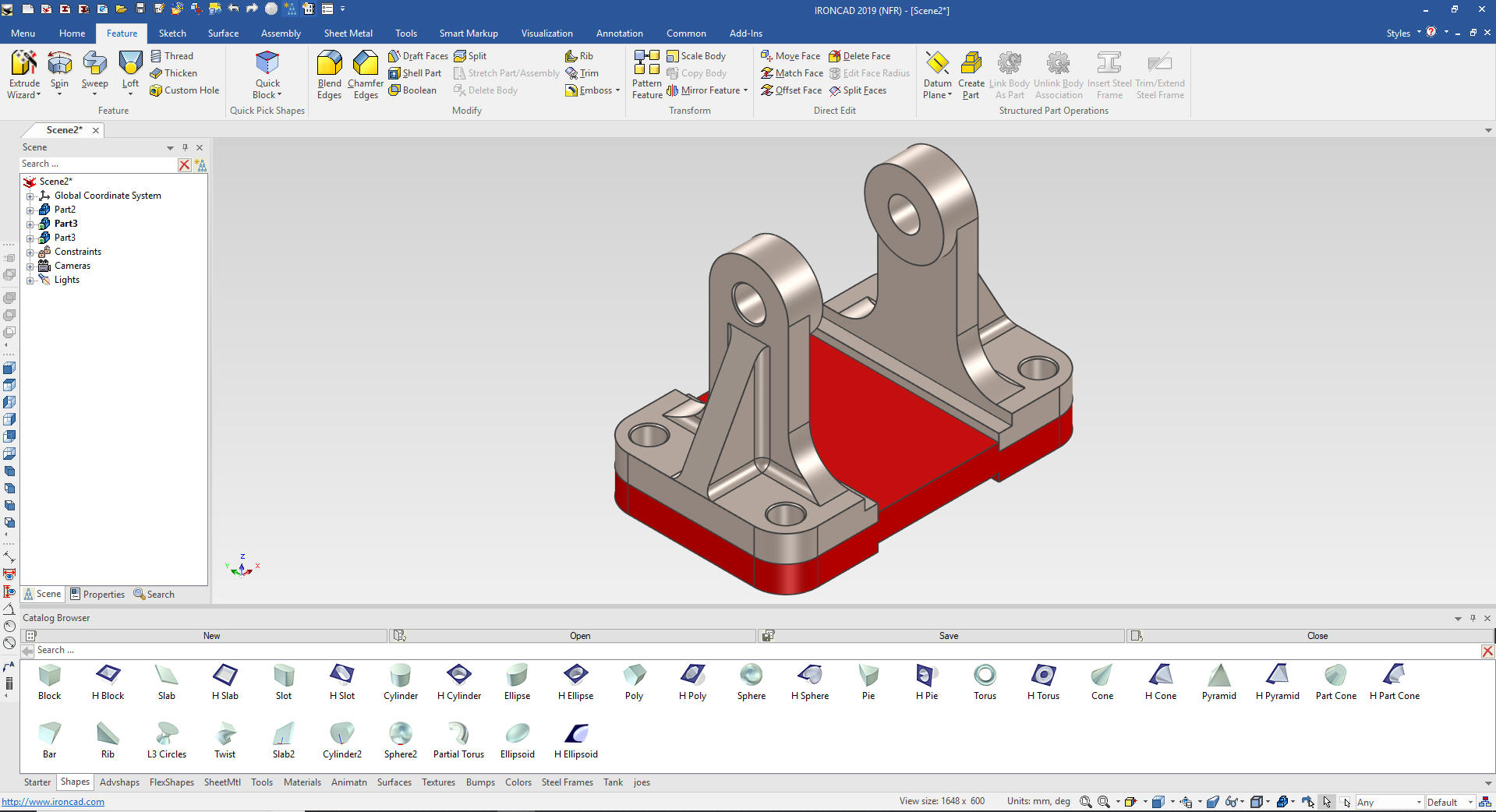

Assembly is the very

best feature of IronCAD. With its true single model environment it

offers the highest level of productivity. Watch how we use drag

and drop with a minimum of sketching to complete this job in no

time. There is no better program that can manipulate parts and an

assemblies in a 3D space.

While creating 3D models from a drawing is the very best

way to learn 3D CAD and maybe some design techniques is does not

expose the designer to the design flexibility necessary in product

design. IronCAD is all top down due to the single model environment.

Creating mating parts is a cruise. But modeling is just one aspect of a

well designed productive 3D CAD system.

IronCAD vs Solid Edge

I would do a

video, but I really am not good at it. So I will show you step by

step. I will try and get IronCAD support to create one. They are

very good.

I always create the part before I watch

the Solid Edge Video, so as to not taint my process. Of course,

there are a multitude of ways to create a model. There is no right

way, just more productive ways. But from what I have seen from these

very complicated processes done by the Solid Edge presenter, it is not

just limited by the 3D CAD system.

I have to say this is

incredibly simple. But the Solid Edge presenter has been

indoctrinated into these designs techniques. It started with Pro/e (Creo)

and has been the way the sketch, constrain and assemble. The

Solidworks clones are costing the industry millions, if not billions,

in lost productivity.

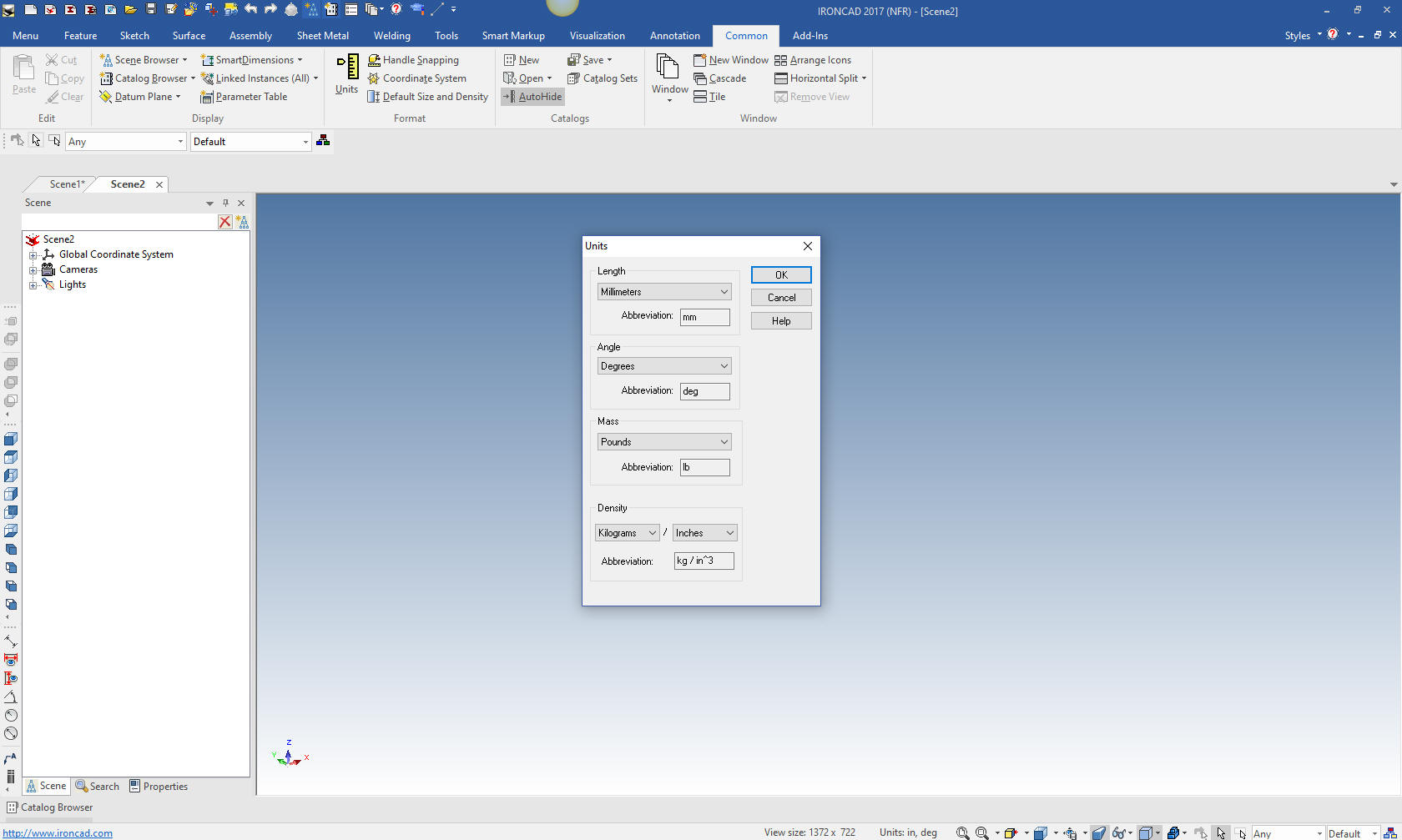

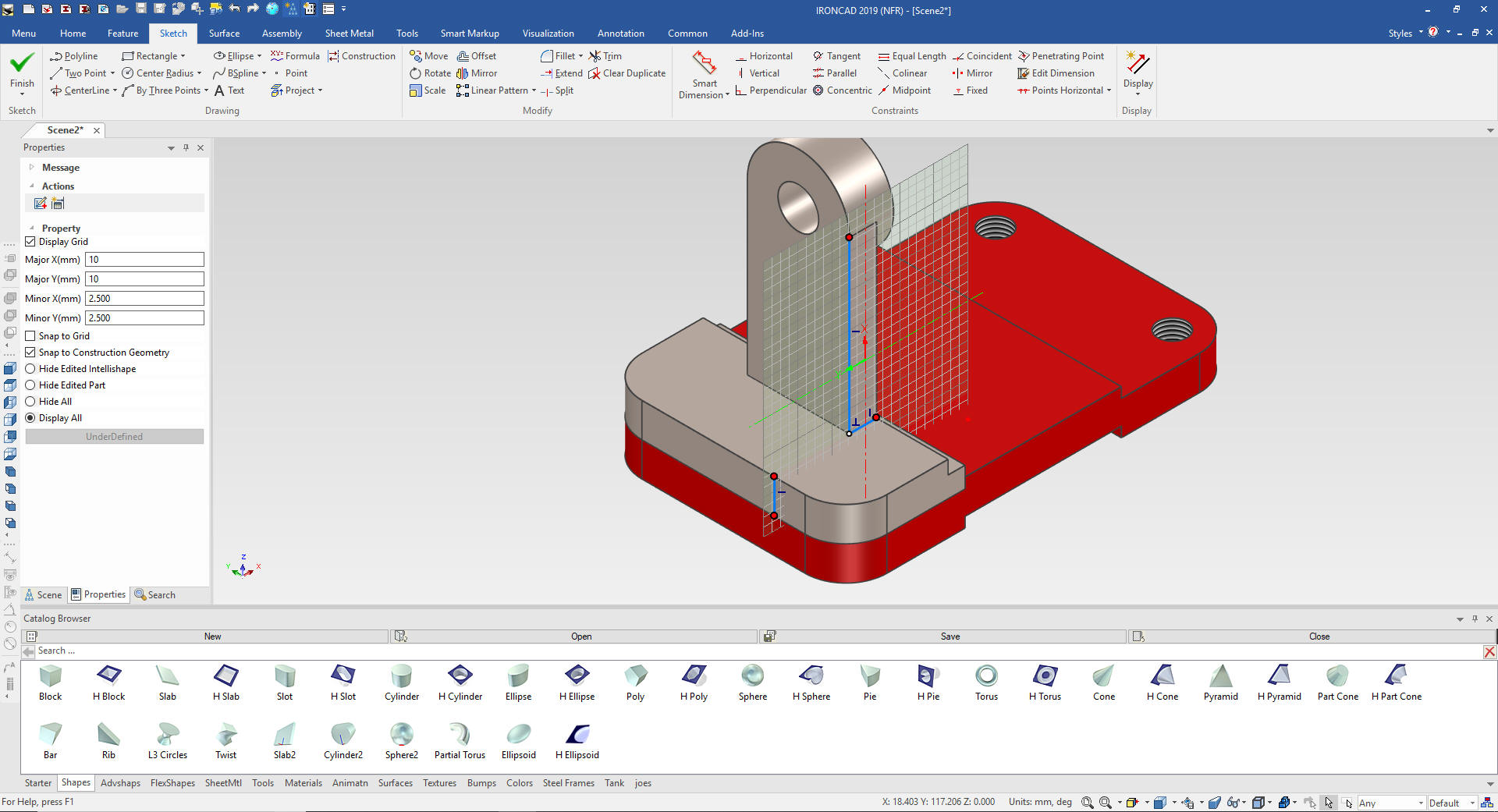

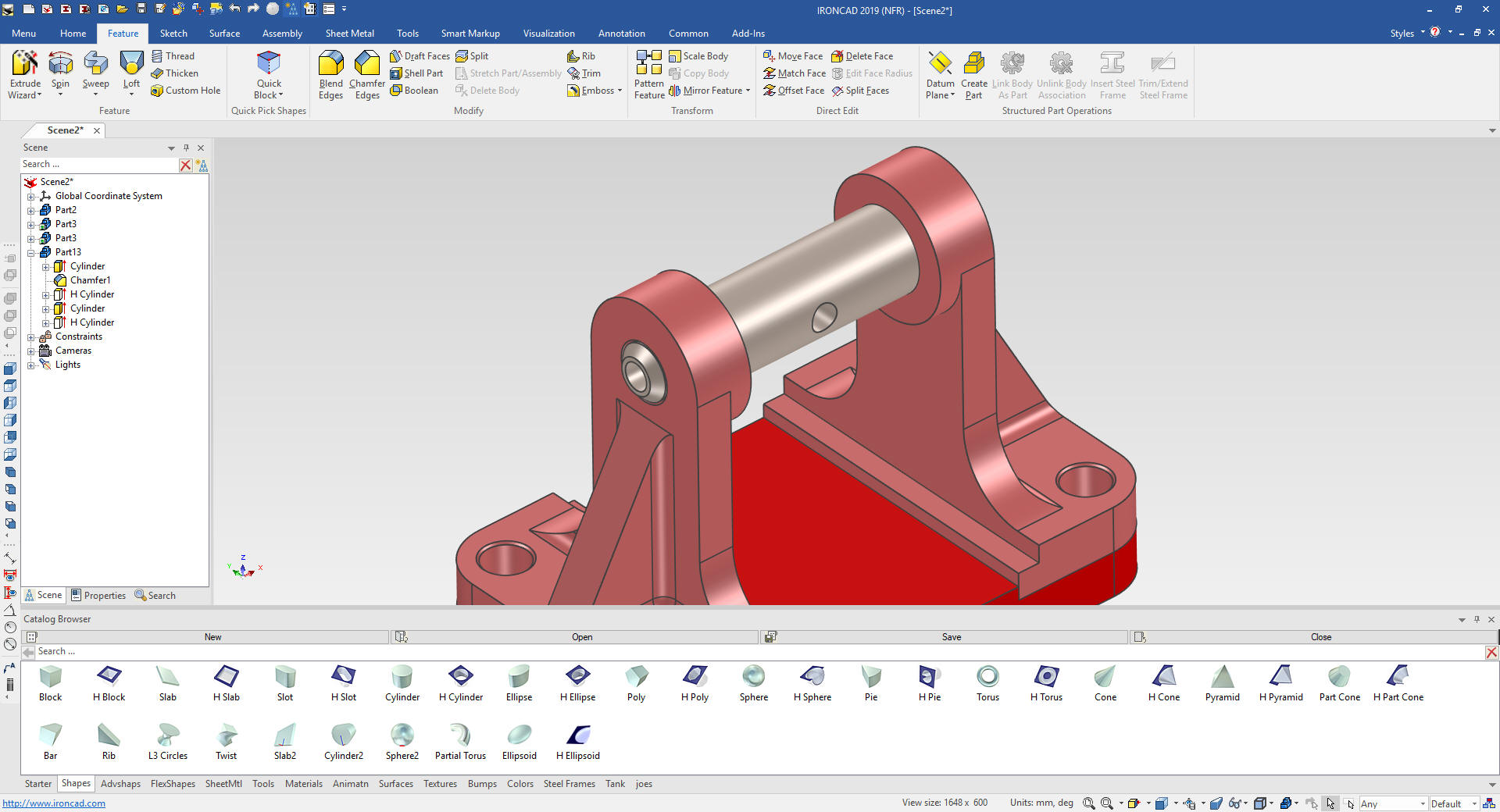

Here is IronCAD. We will set the units

to millimeters.

Learning IronCAD! Lesson 1

Setting up the Scene (Workspace)

With IronCAD's single model environment

we do not have to prepare for it being an assembly. We just start

creating our part.

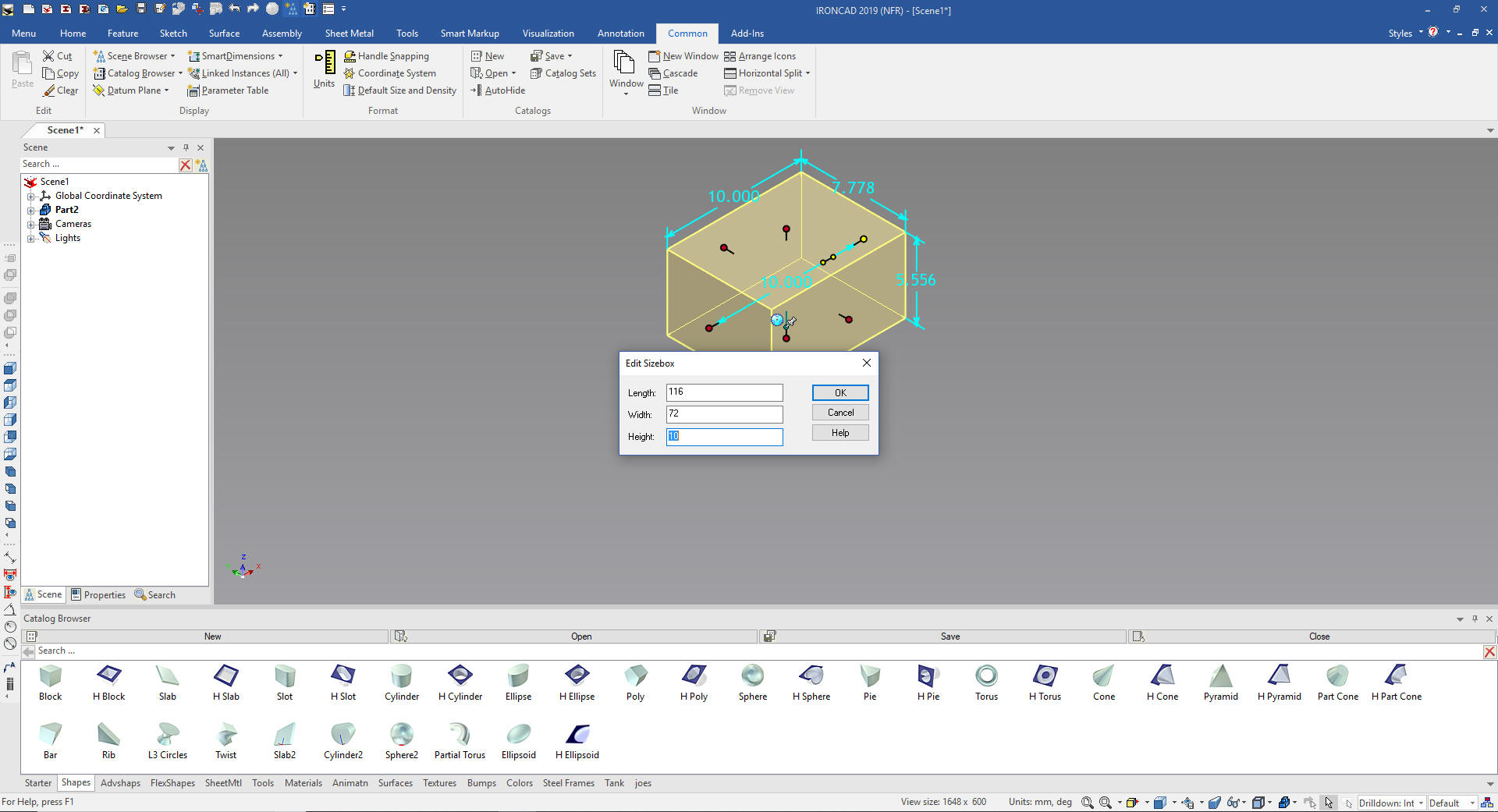

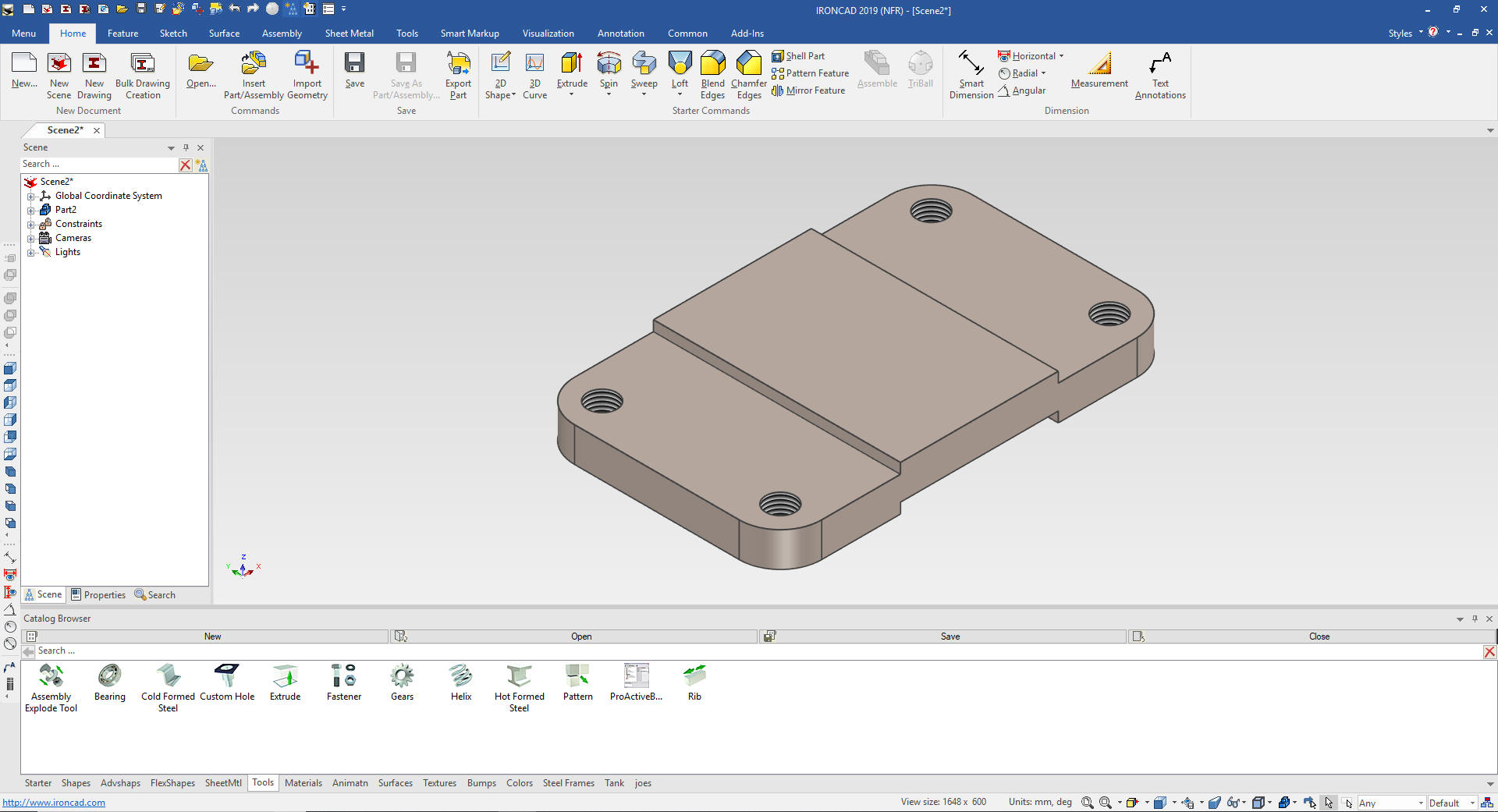

We will start by dragging and dropping a

block from the catalog and sizing it.

Learning IronCAD! Lesson Two

Drag and Drop Design

Designing with

Shapes

What are these shapes? We call them

Intellishapes. All are based on sketches that can be edited.

Learning IronCAD! Lesson 4

IronCAD Intellishape Deconstructed

What are

we Dragging and Dropping?

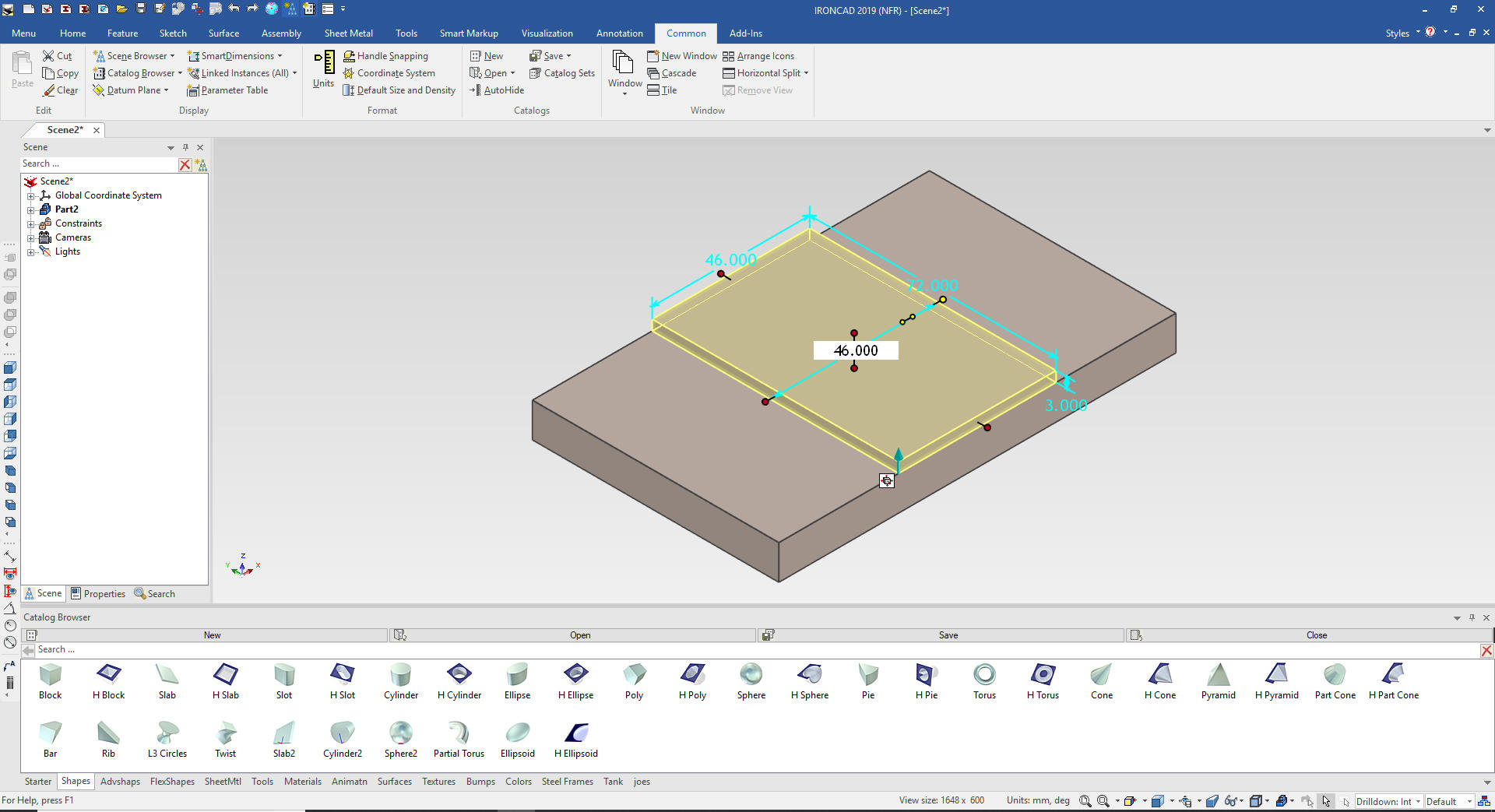

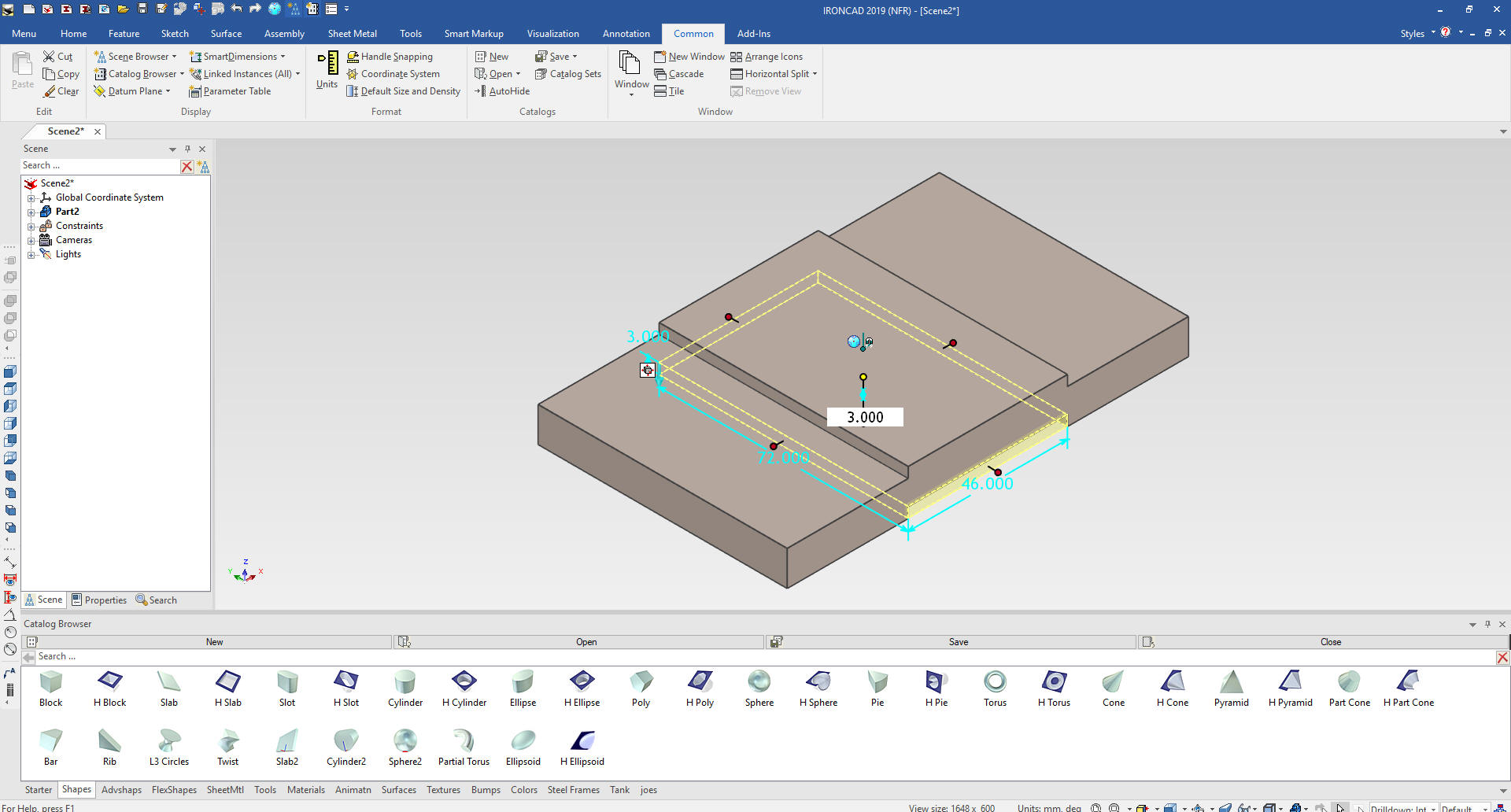

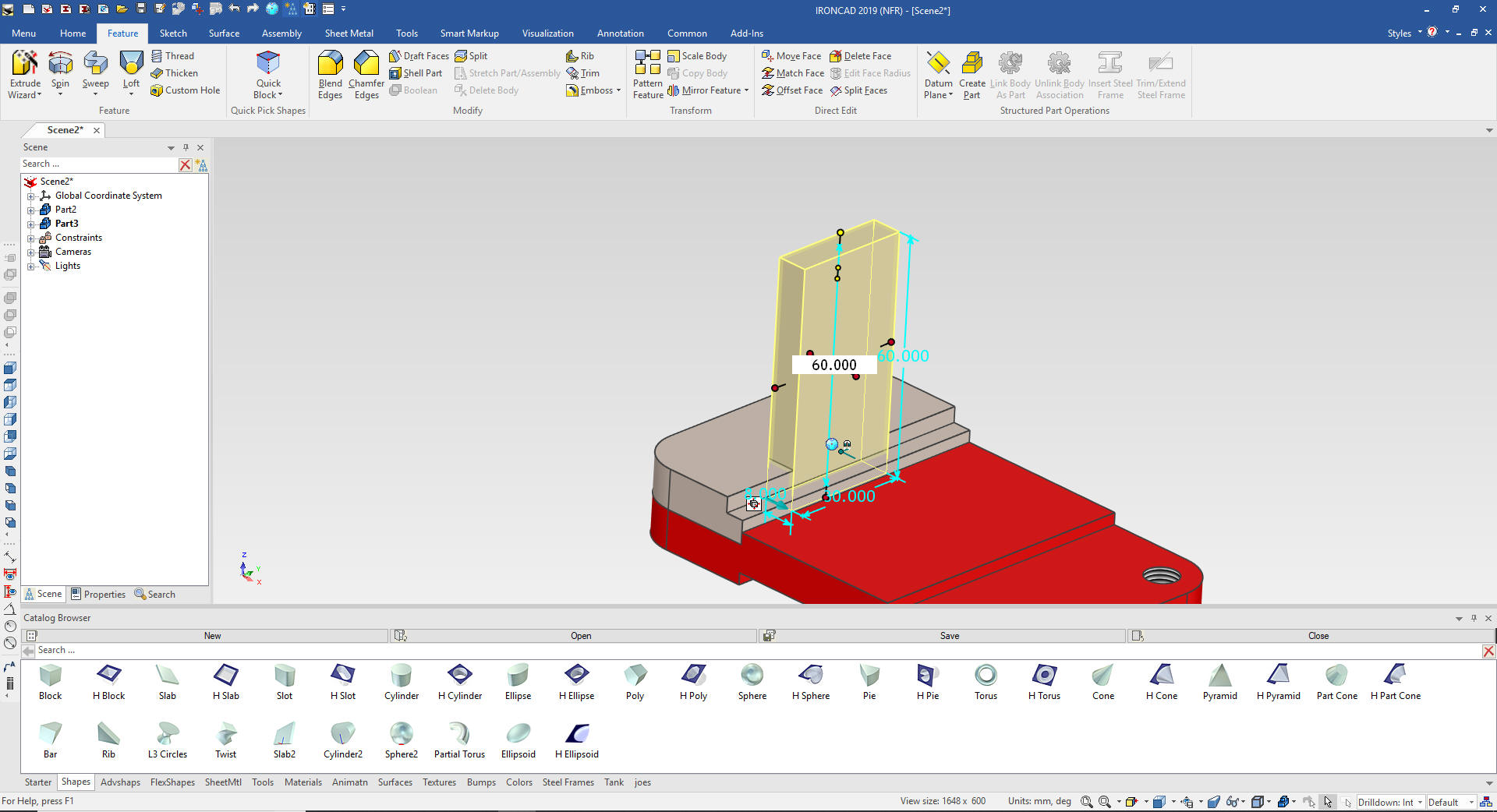

We then drag and drop another block and

locate it at mid-point of the top of the rectangle and size it by

pulling the side handle, holding down the shift key and matching the

edges, we set the height to 3 and then the length to 46. You can drop the feature on a variety of

snap points on the

part such as corners, edges, mid-points and centers.

Learning IronCAD! Lesson Two

Drag and Drop Design

Designing with

Shapes

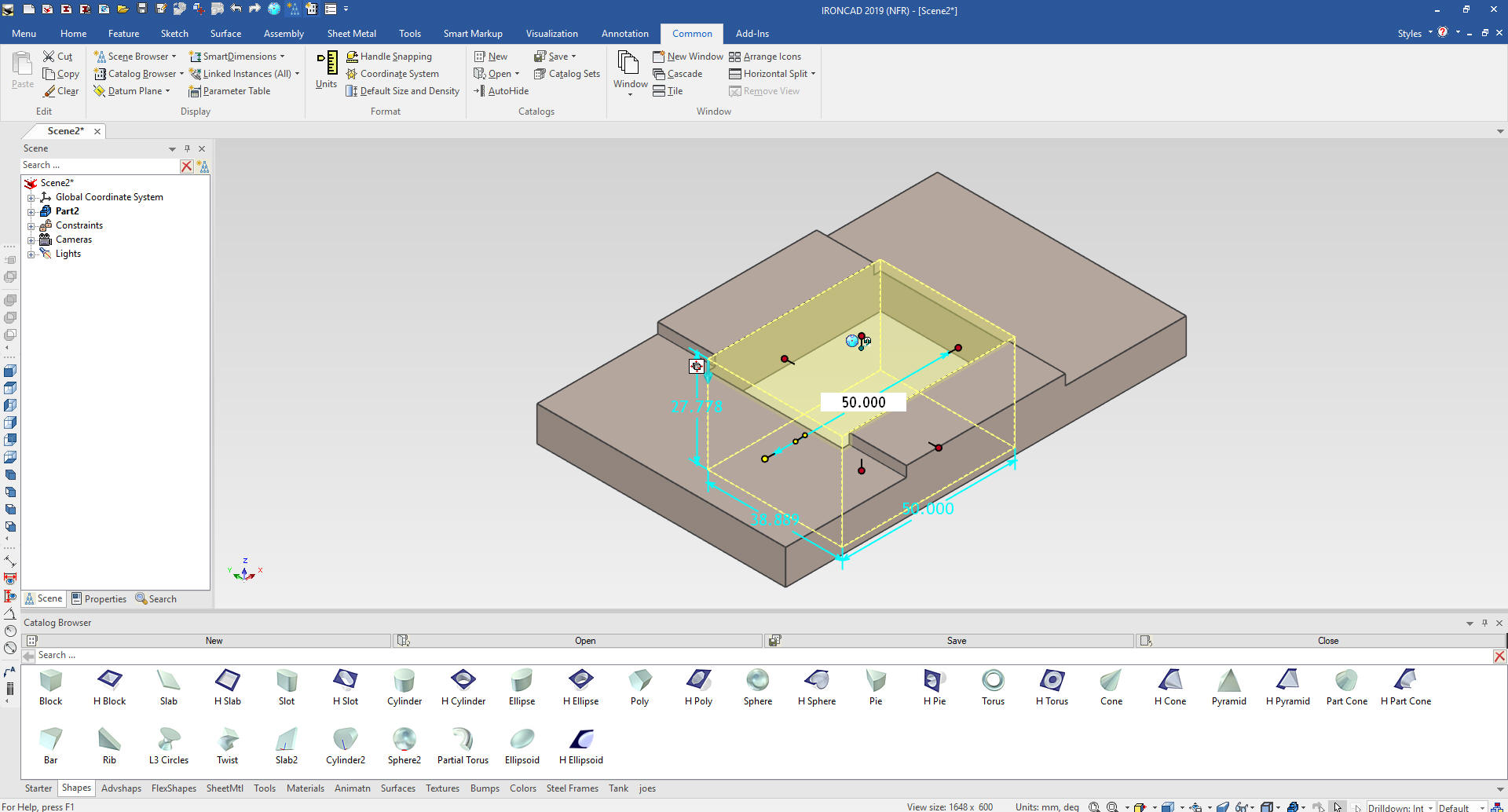

We drag and drop a hole block at the

mid-point of the top face.

We grab the handles, hold down the shift

key and match the related faces and set the height to 3.

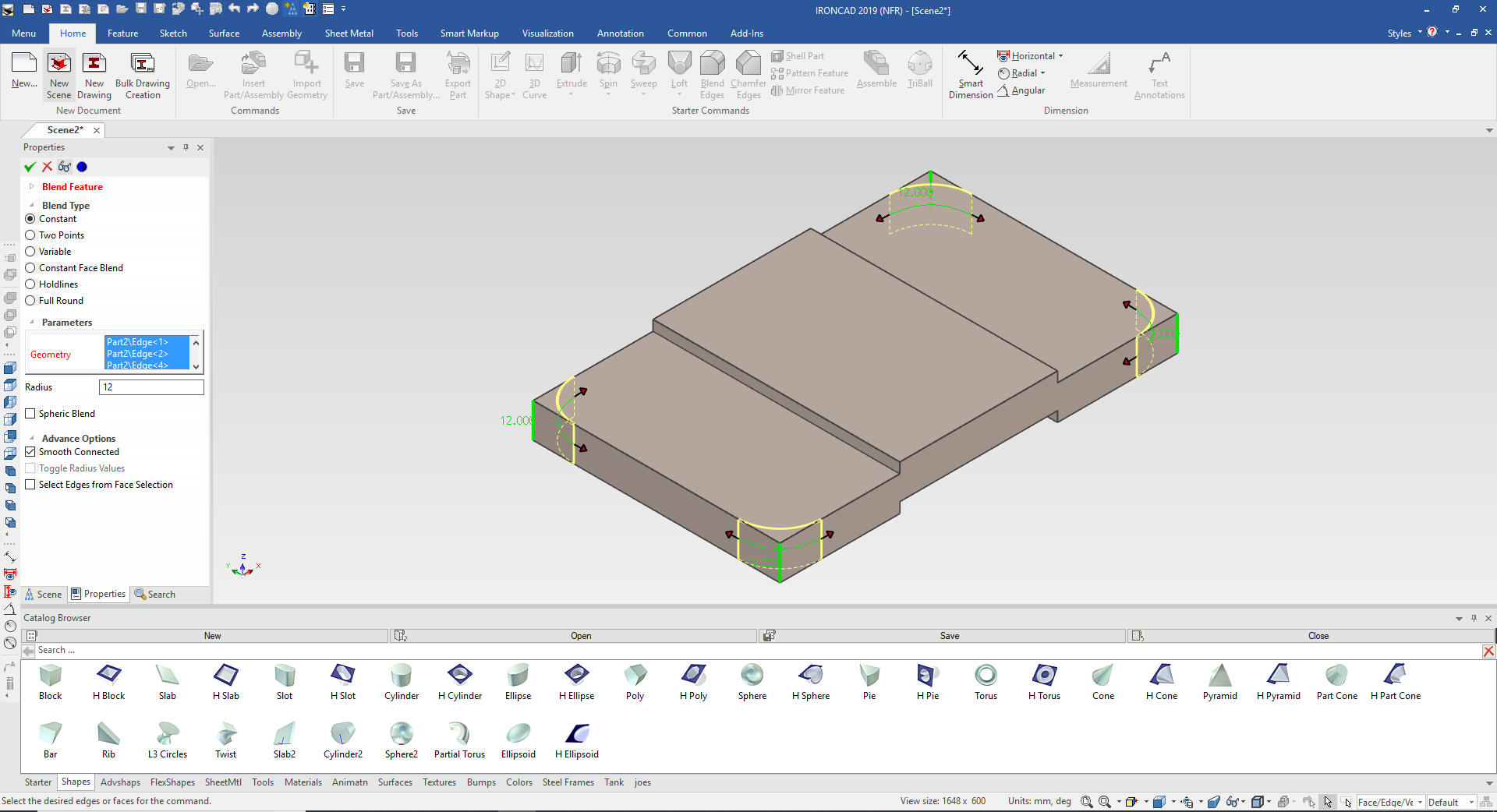

We put in the

4 12mm blends or fillets

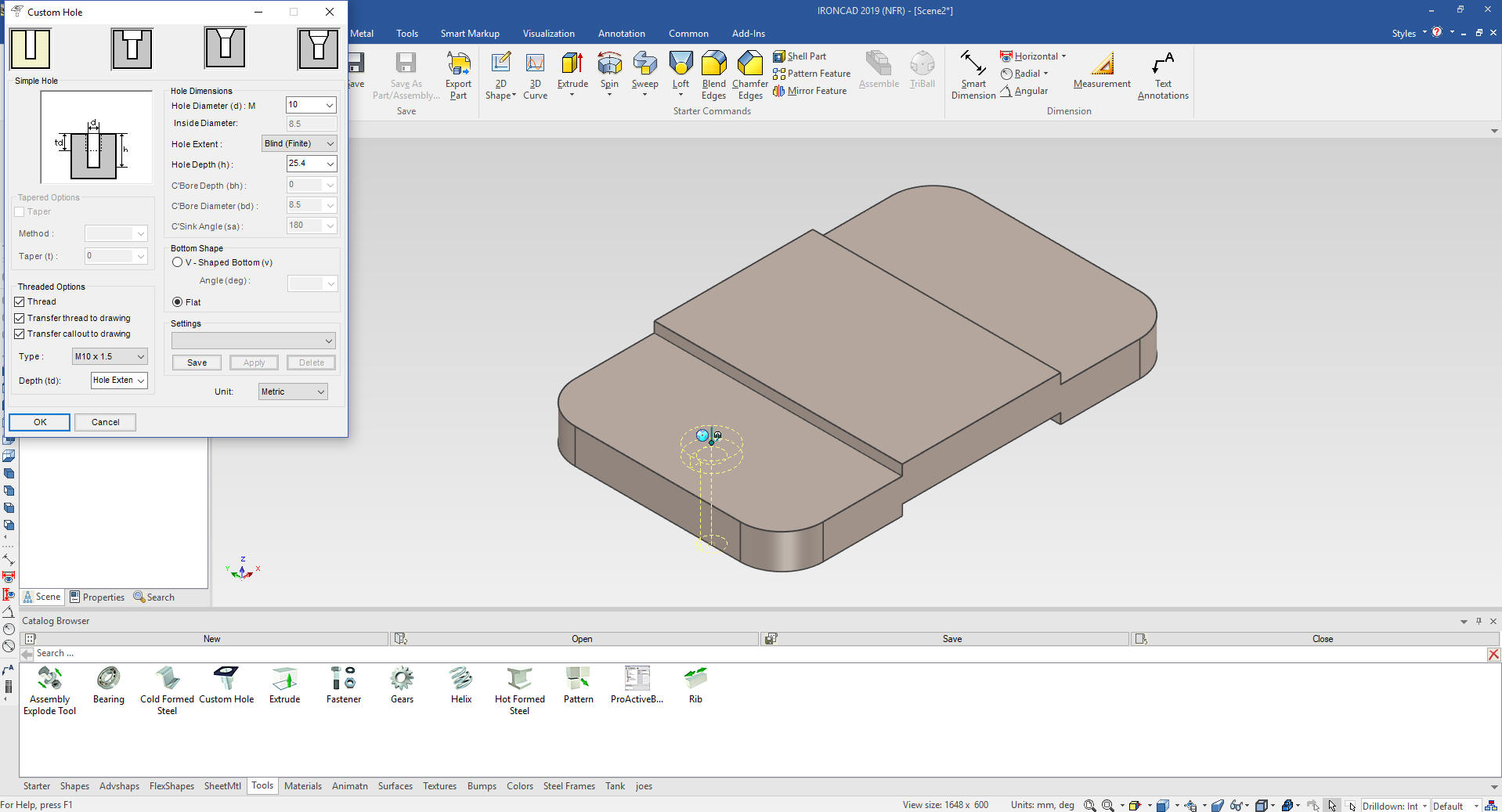

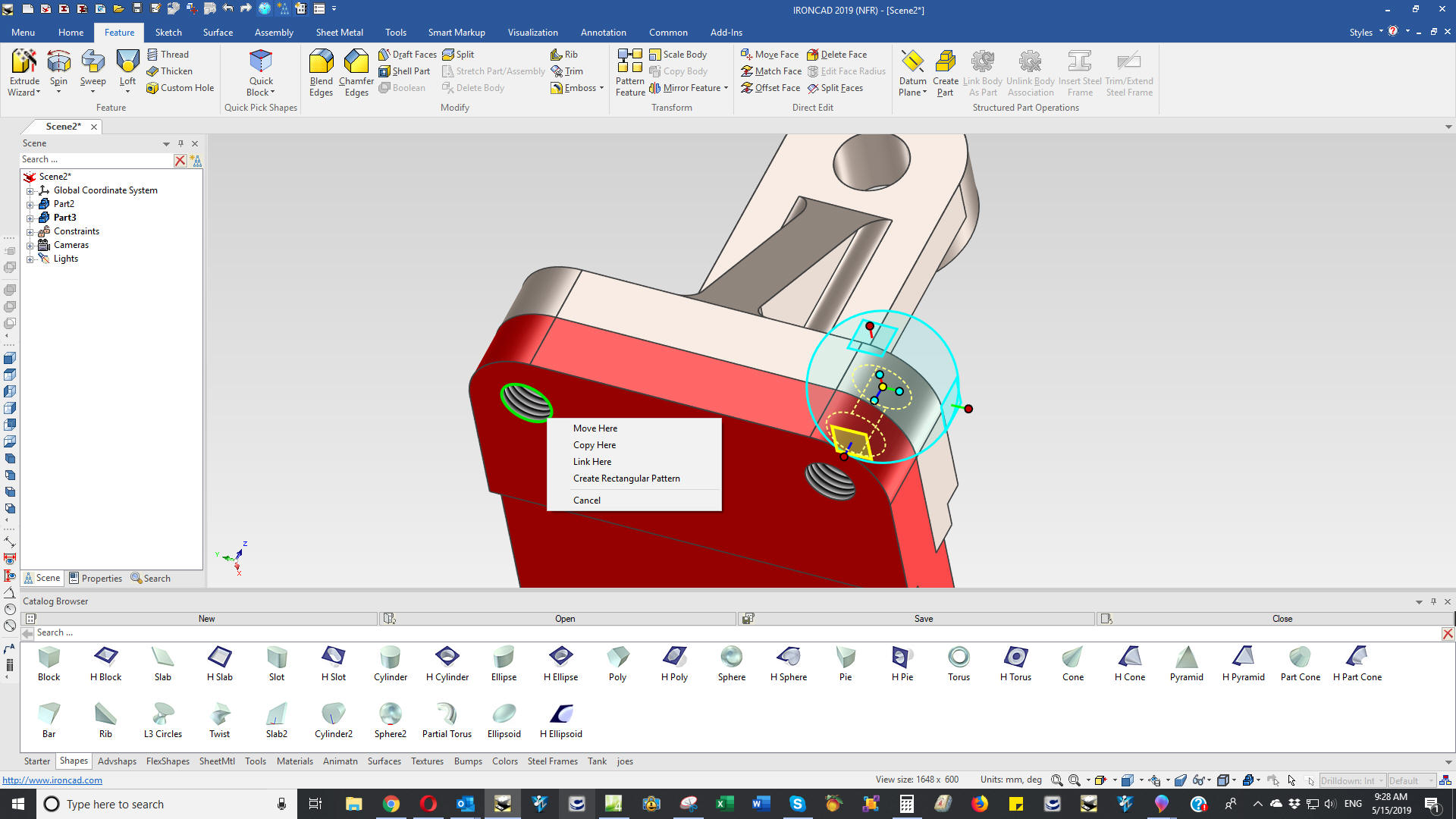

We will put in the 4 M10 holes. We drag

and drop a custom hole from the tool catalog to the mid-point as

shown. I can't believe it is as complicated to locate a hole in

Solid Edge.

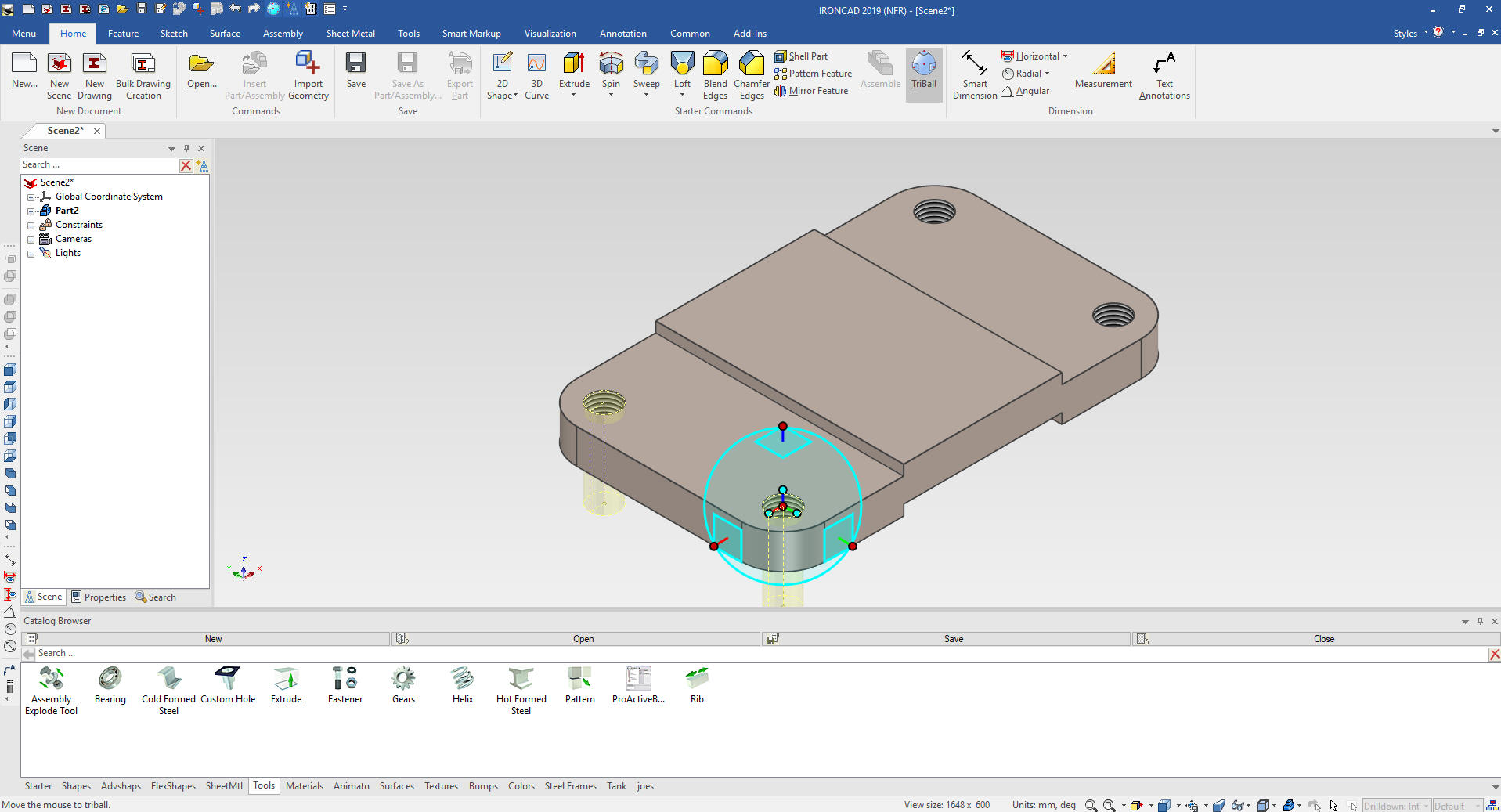

We locate the first hole then locate and

link the other 3 holes using the triball.

The Triball is used throughout the design. I can manipulate

features, parts and assemblies.

We name the part base and we are done.

No sketches were used.

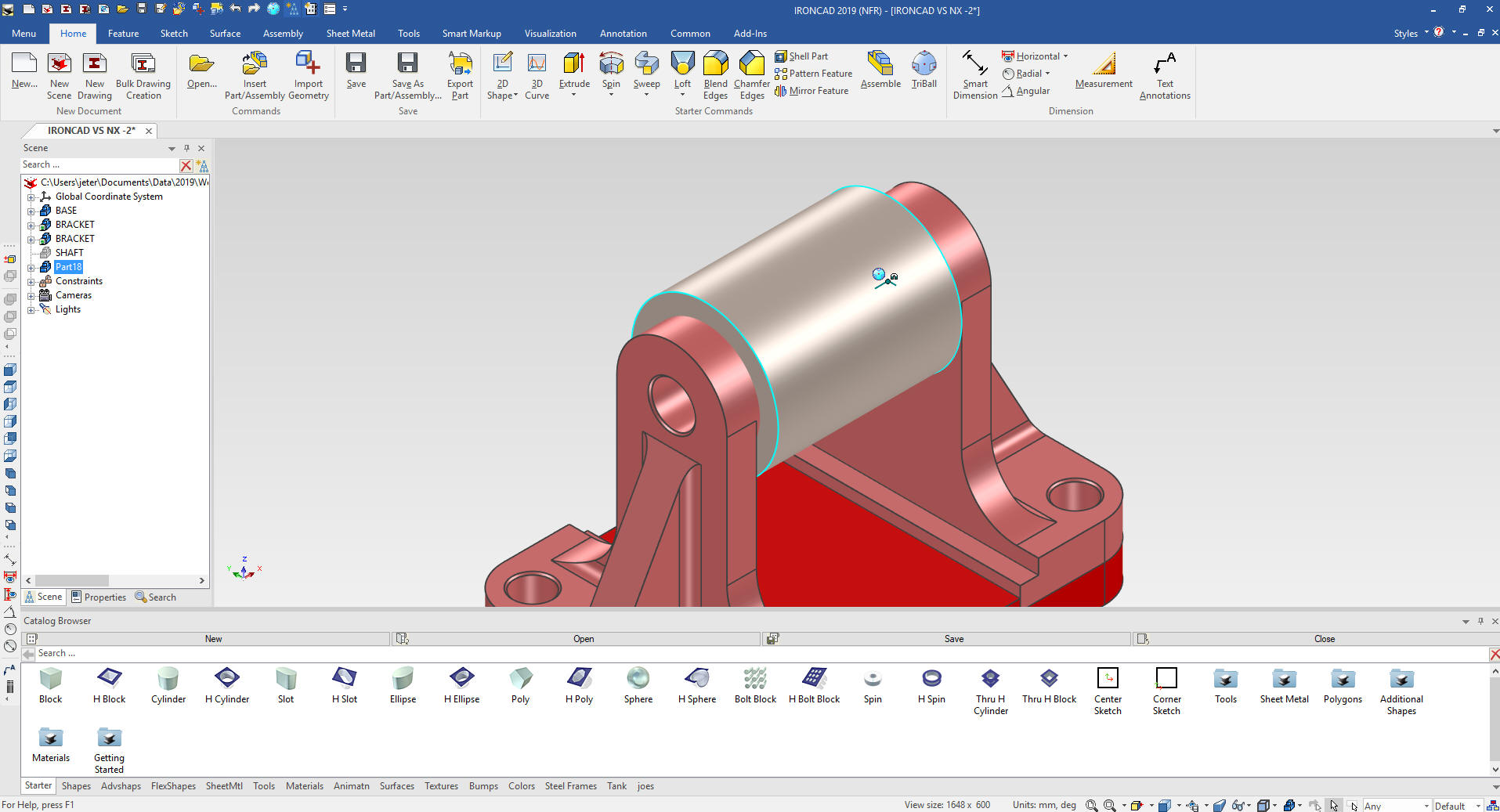

IronCAD was designed from the ground up

for top down or in context design and has many function that make it

much easier.

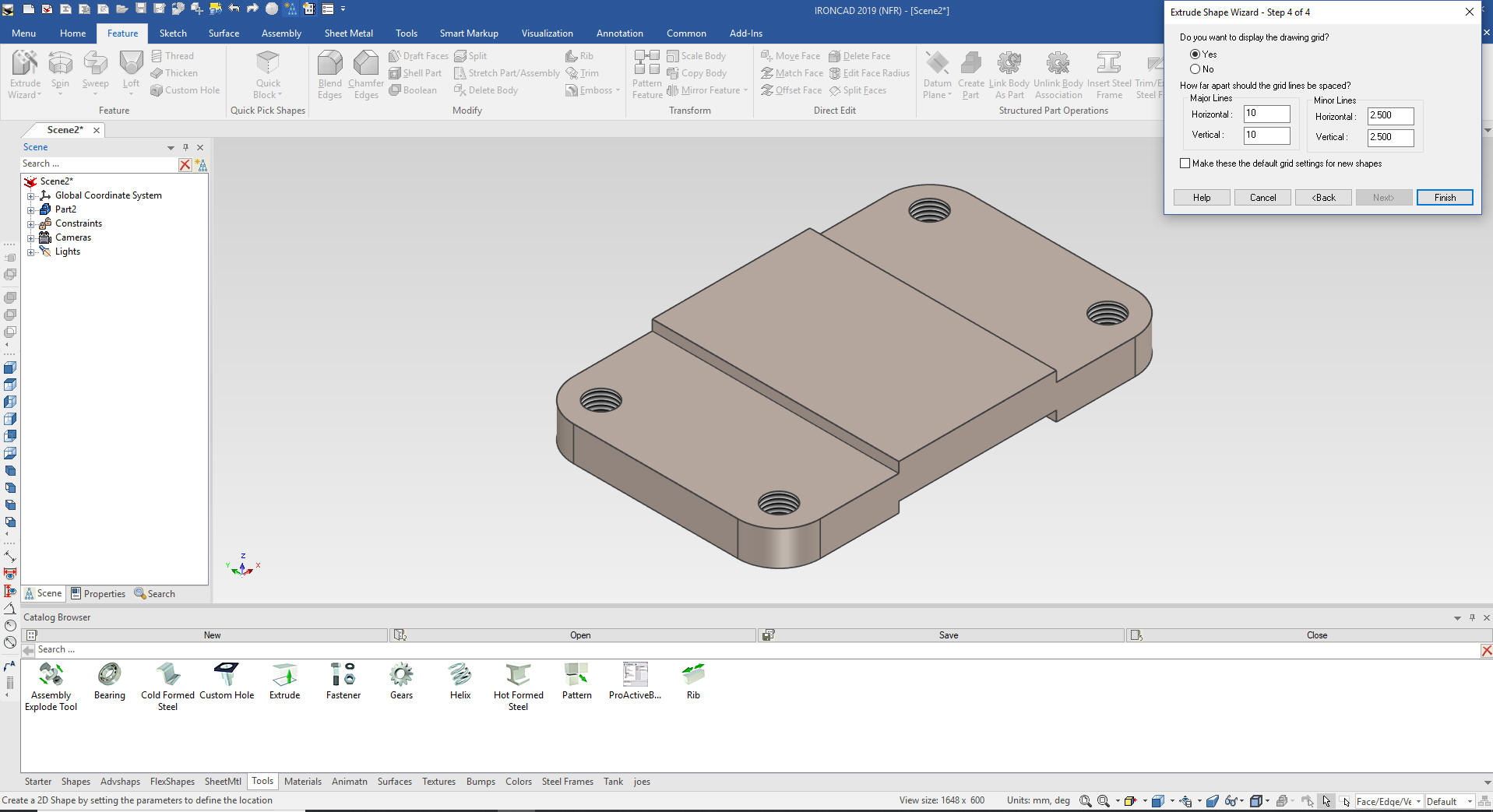

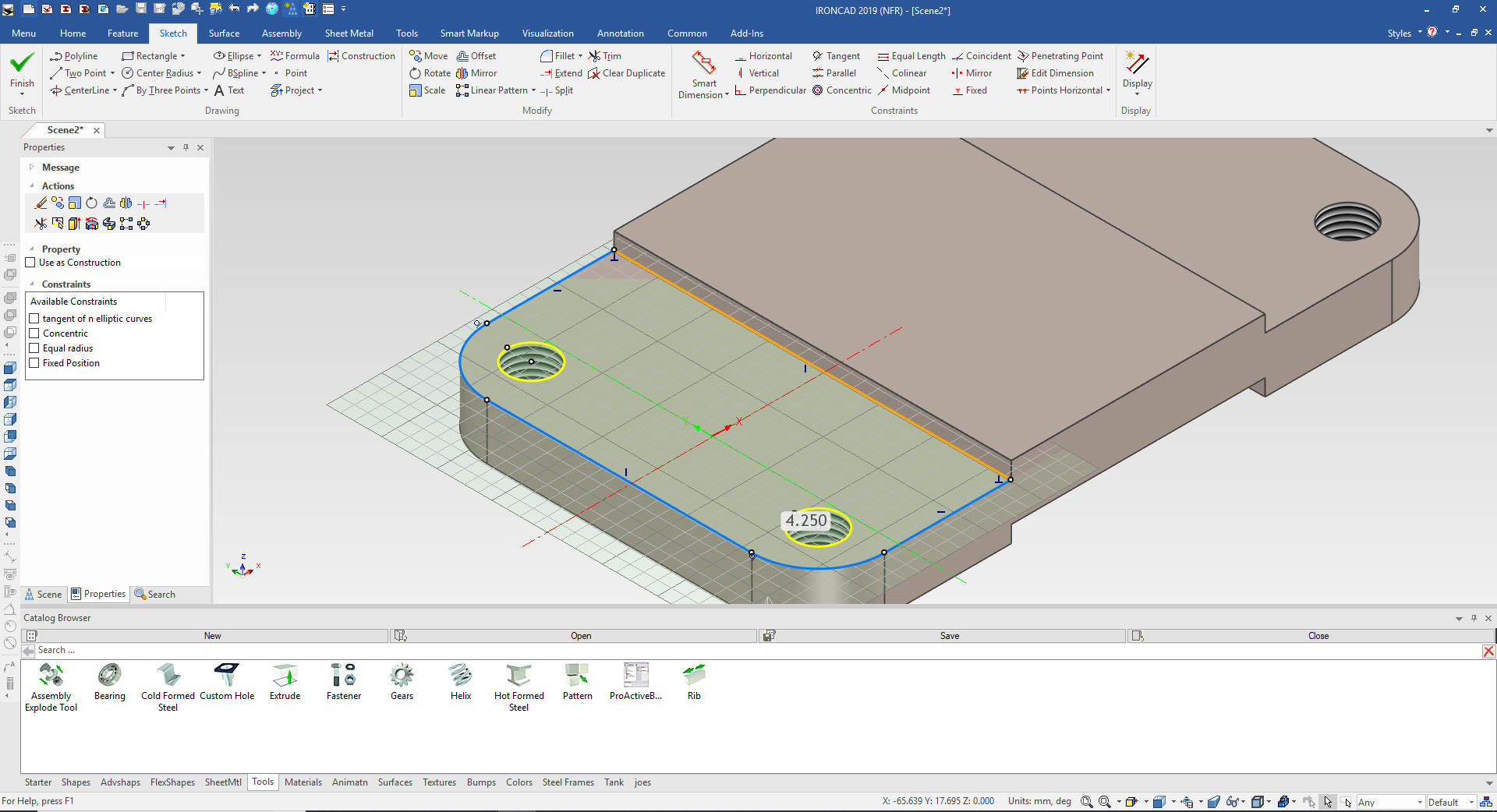

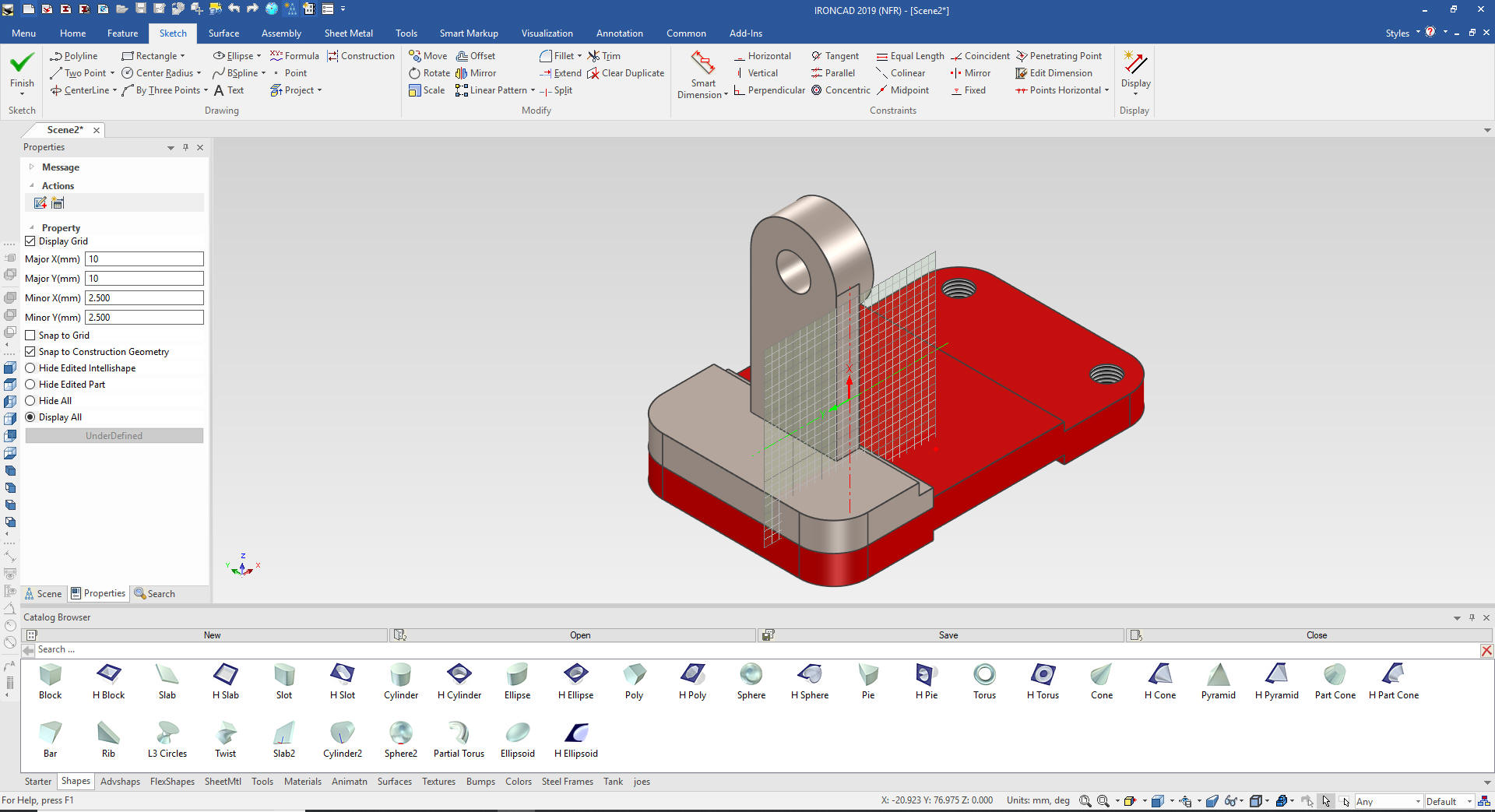

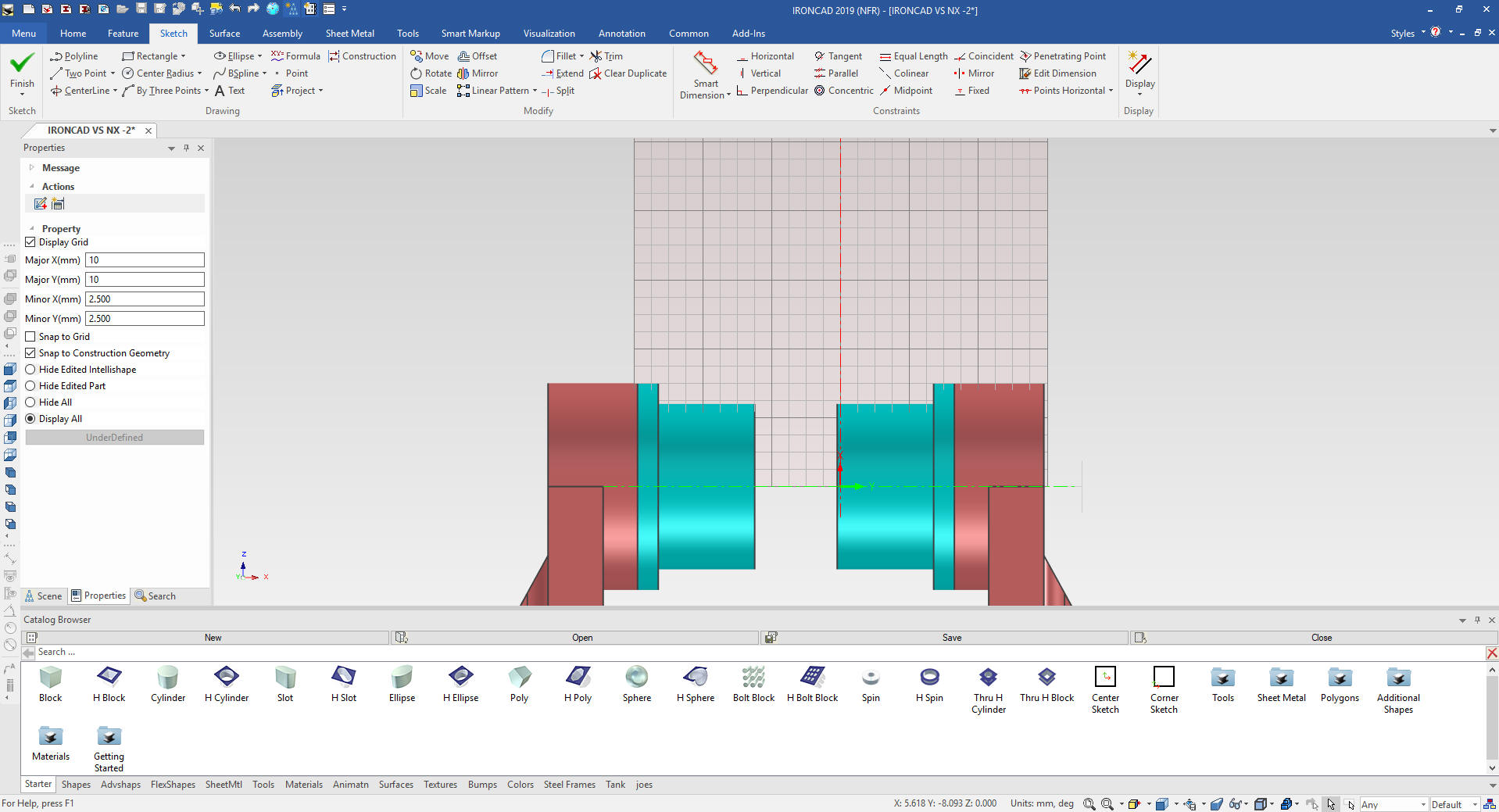

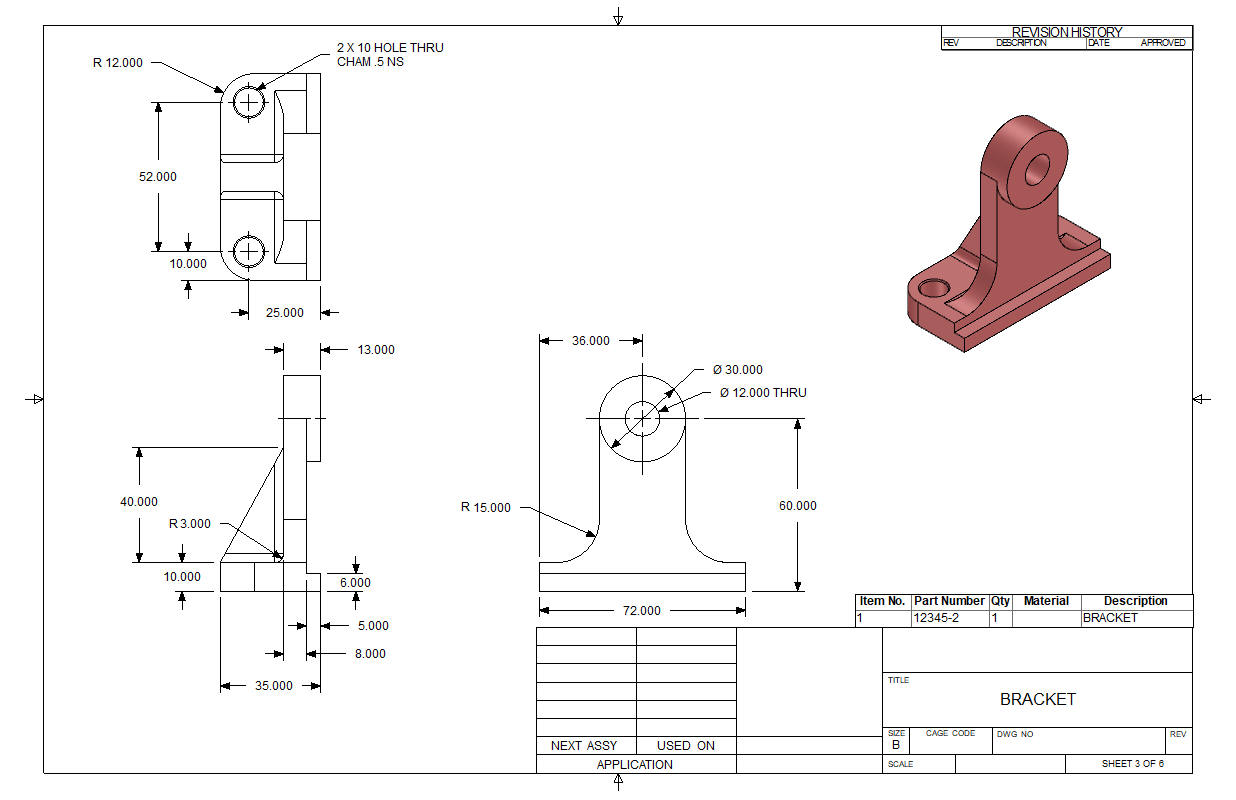

One of those functions is the Extrude Wizard

which will use to start the bracket. We select the Extrude Wizard

and select the front top face and in the dialog box we pick stand

alone and set it for 10mm.

We select project from the sketch menu

and select the front top face and that creates our sketch. We do not

want the holes so we delete them.

Yes we use sketches in our

designs. The Extrude Wizard is one of the main tools in in context

design in making mating parts.

We just

select okay and we have the base for the bracket.

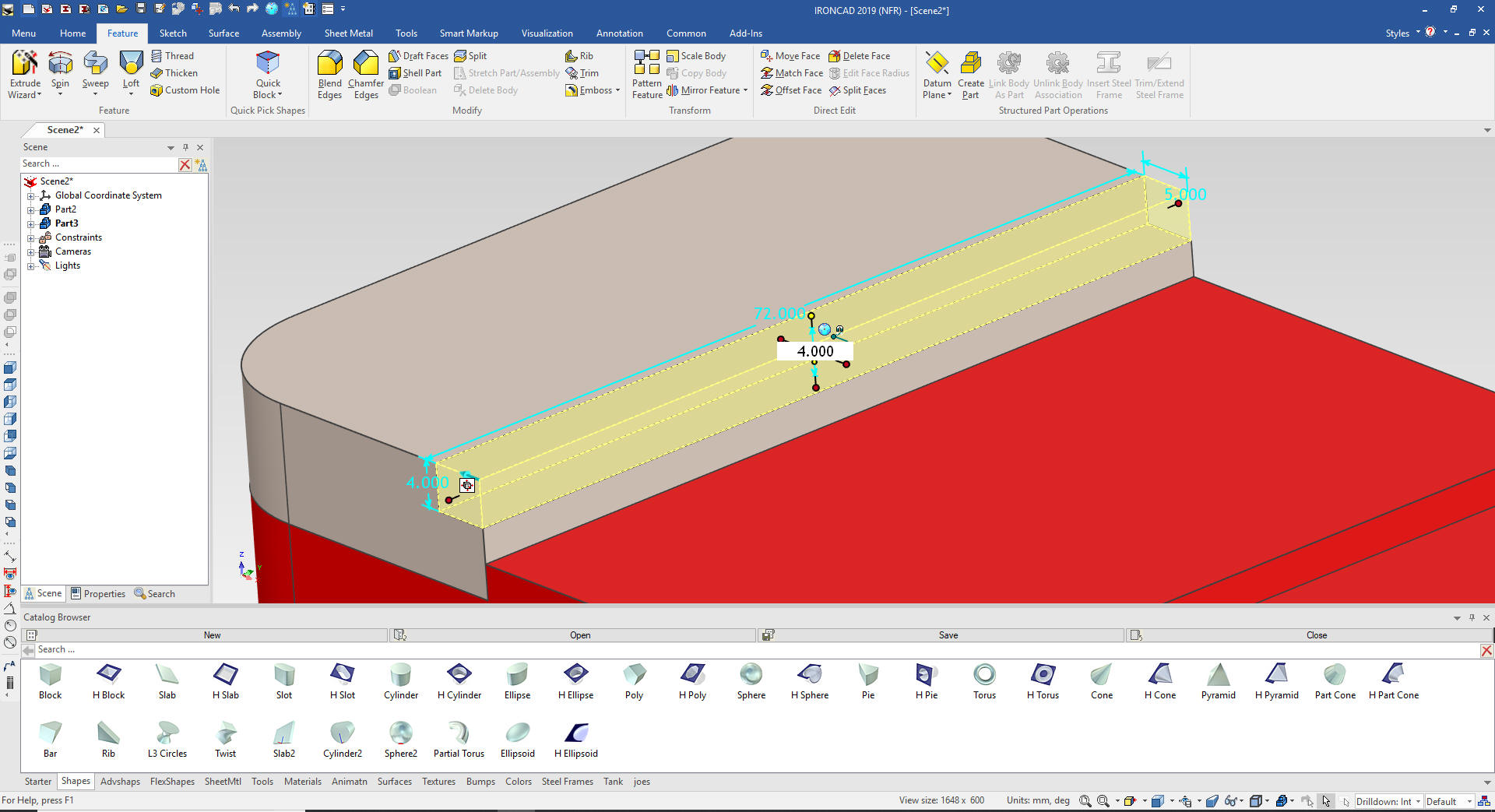

We change

the color on the base for clarity.

We

add the front cut by dragging and dropping a hole block to front

edge of the bracket base.

I

drag and drop a block to the edge of the related face of the bracket

base and size the block.

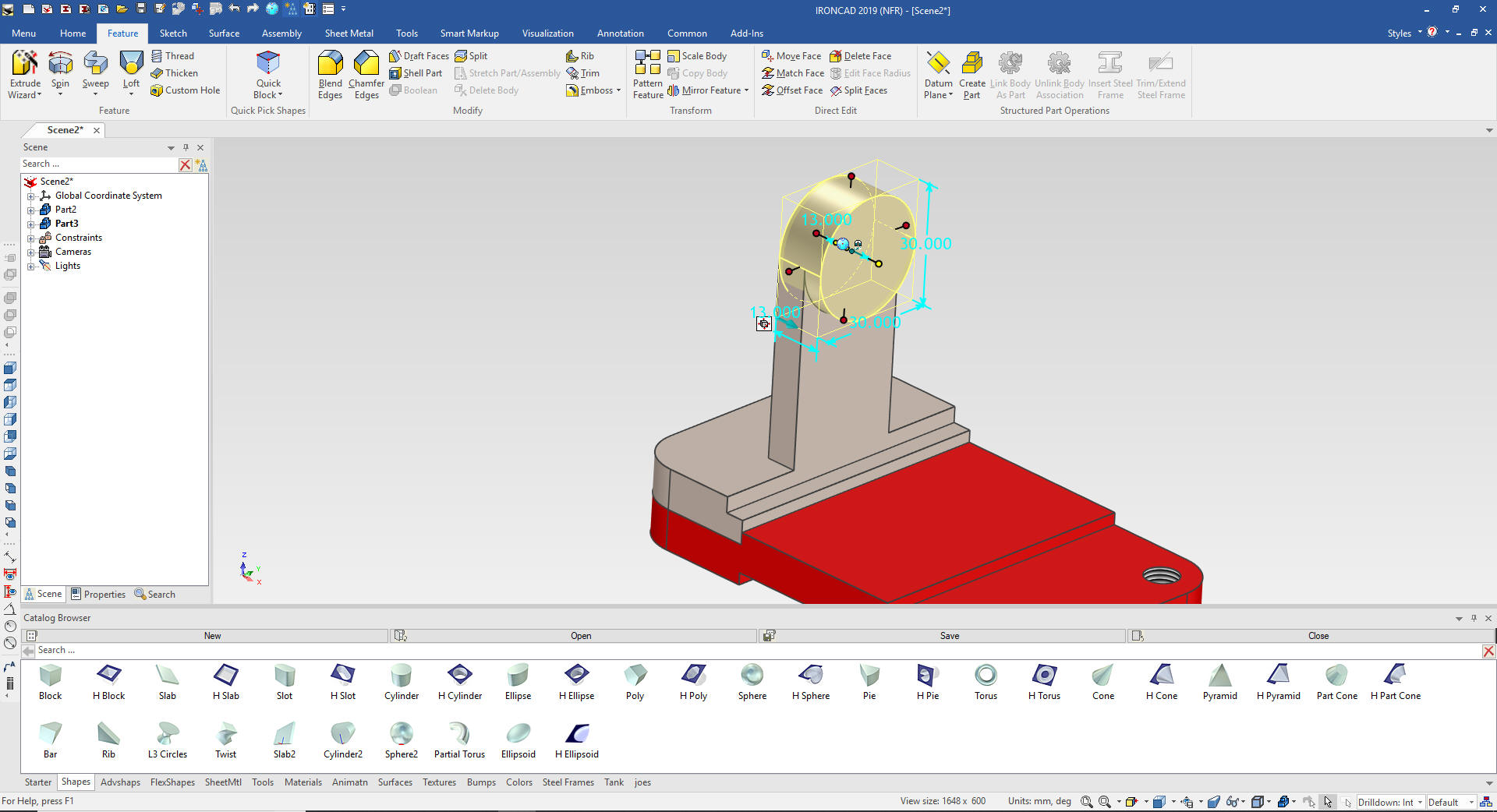

I

will drag and drop a cylinder on the upper edge of the block.

IronCAD knows depending on how the faces are viewed how to orient

the dragged intellishape. We then size the cylinder.

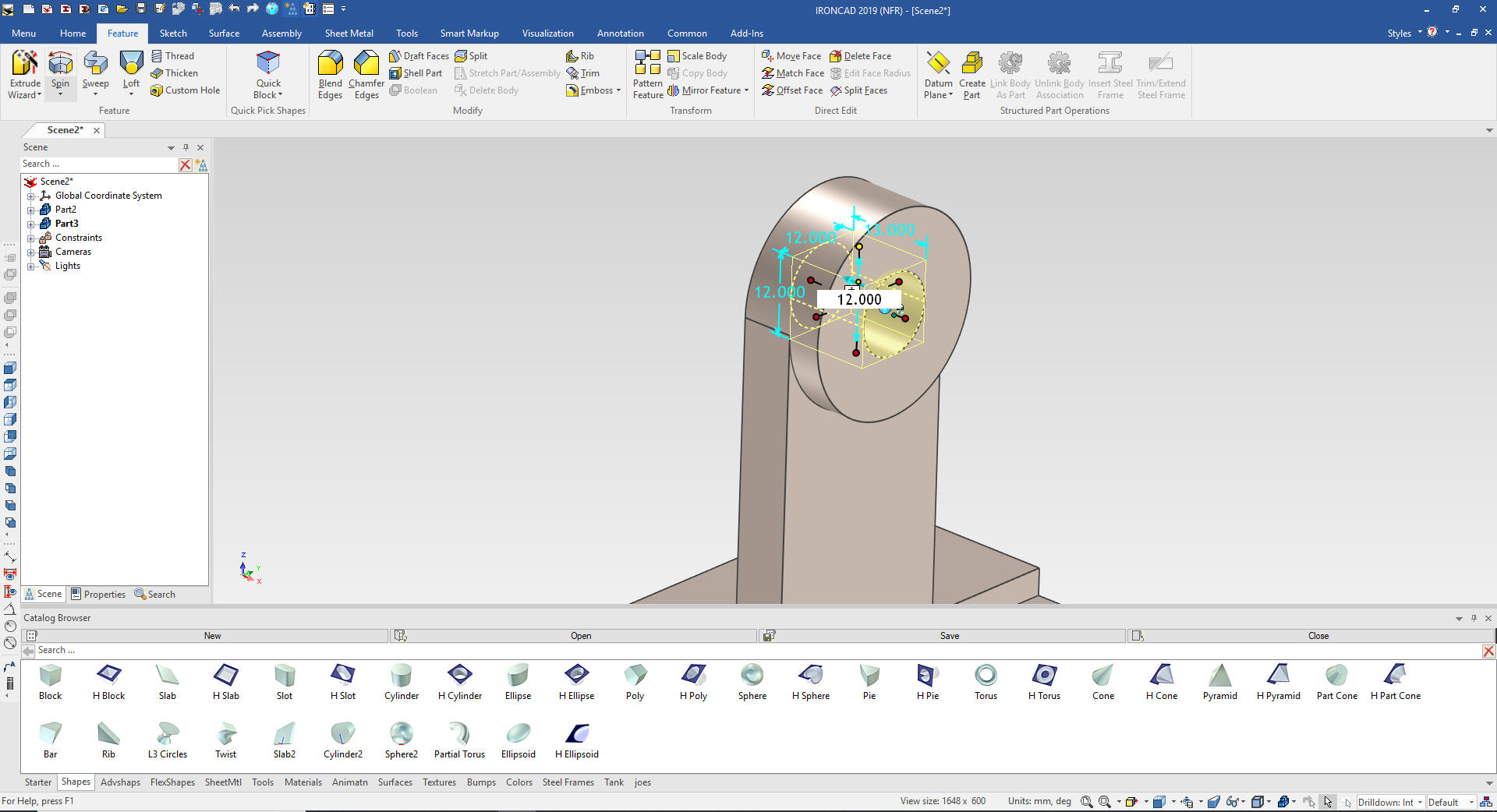

We

add the hole by dragging and dropping a cylinder to the center of

the boss and sized.

And

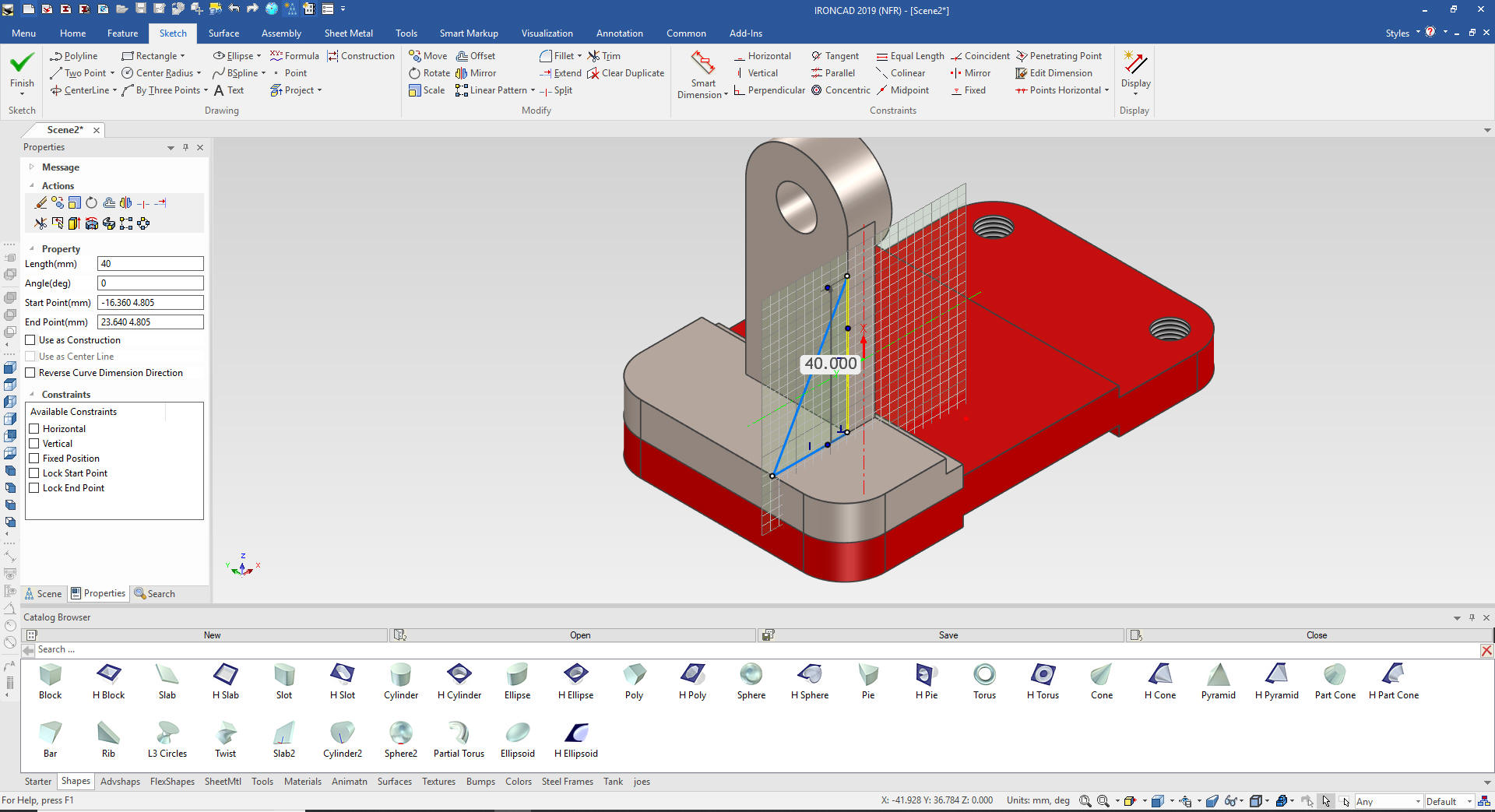

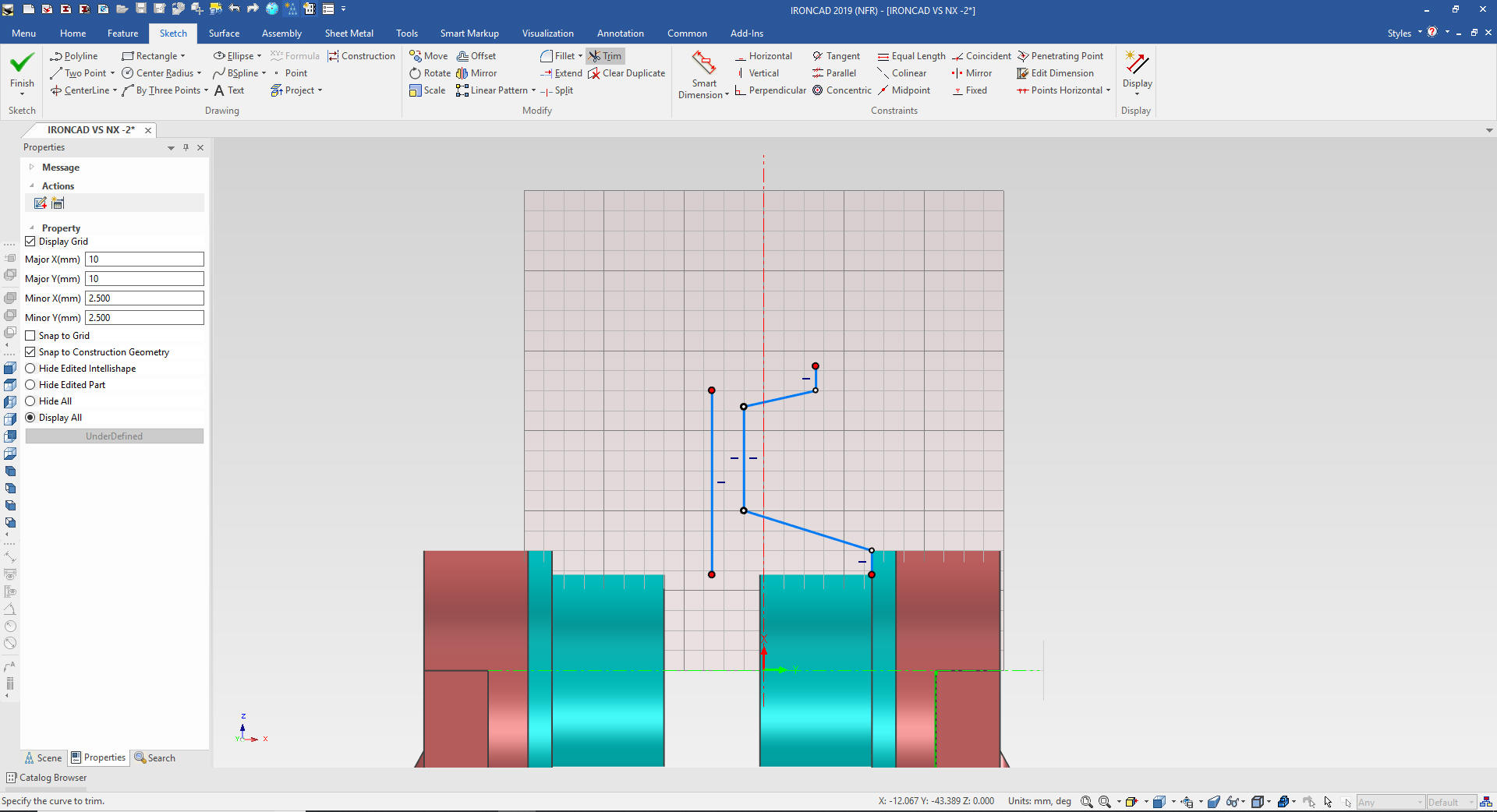

now for the rib. We again use the Extrude Wizard to add a feature

not to create a mating part. IronCAD also has a standalone sketching

function for development or for using .dxf/.dwg 2D graphic imports.

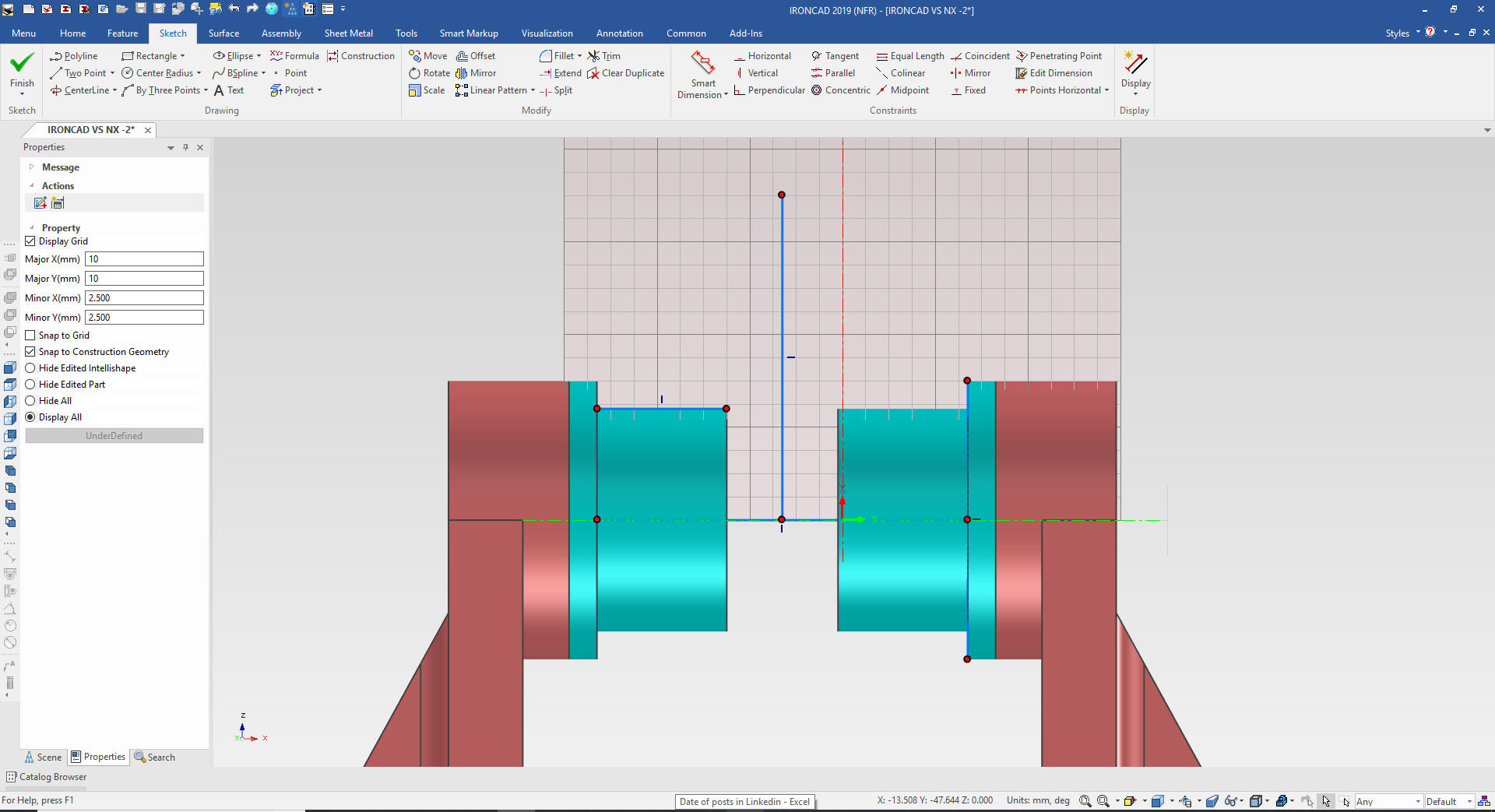

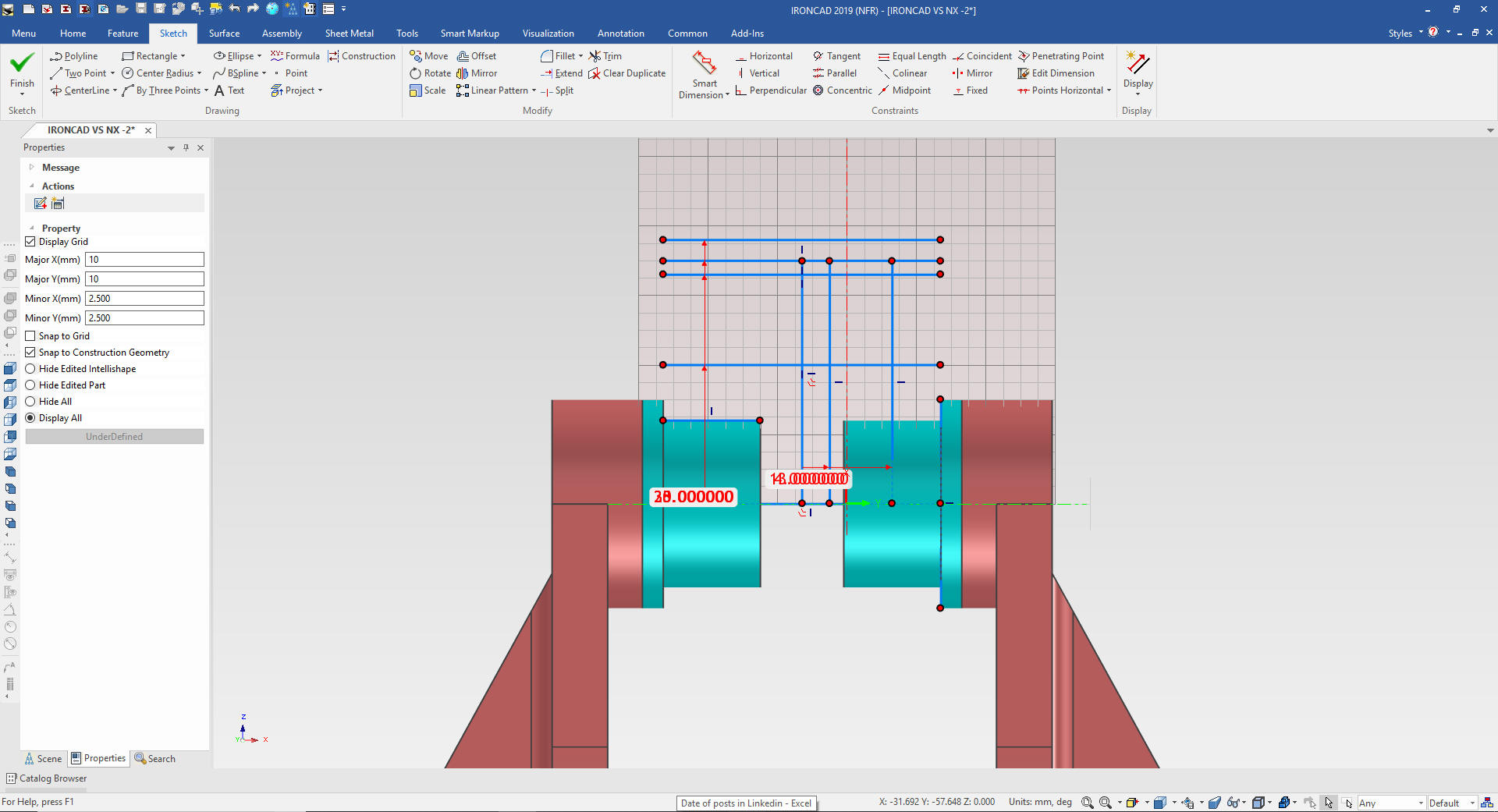

We project the relative edges necessary to create the rib.

We edit the vertical line to 40 and extend and trim the bottom line.

Delete the construction line and connect the dots. A red dot means

then lines are not connected and the sketch will fail.

Note:

I was talking to one of my associates and realized I could have drag

and dropped a rib intellishape on to the part, eliminating the need

for the sketch!

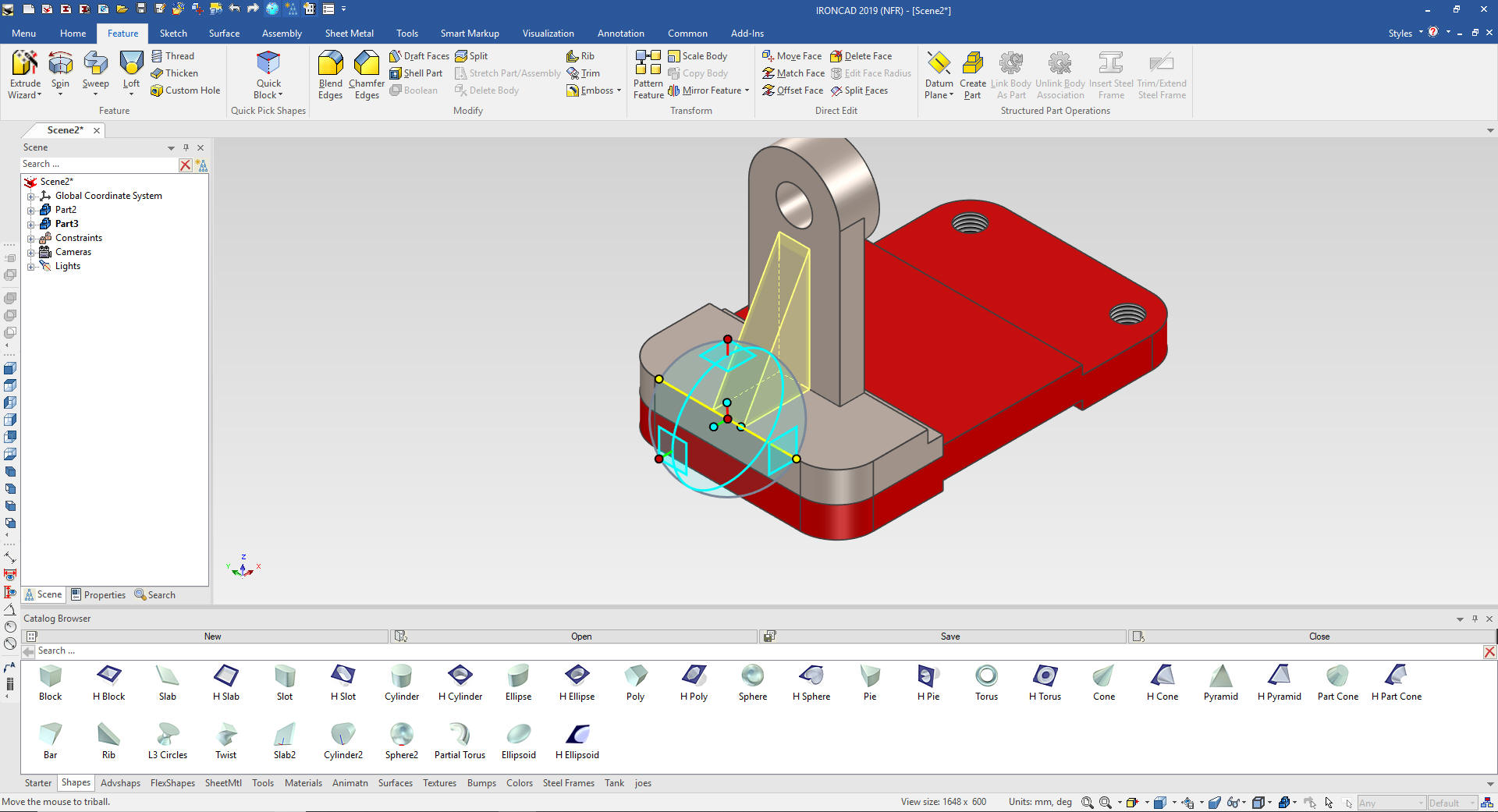

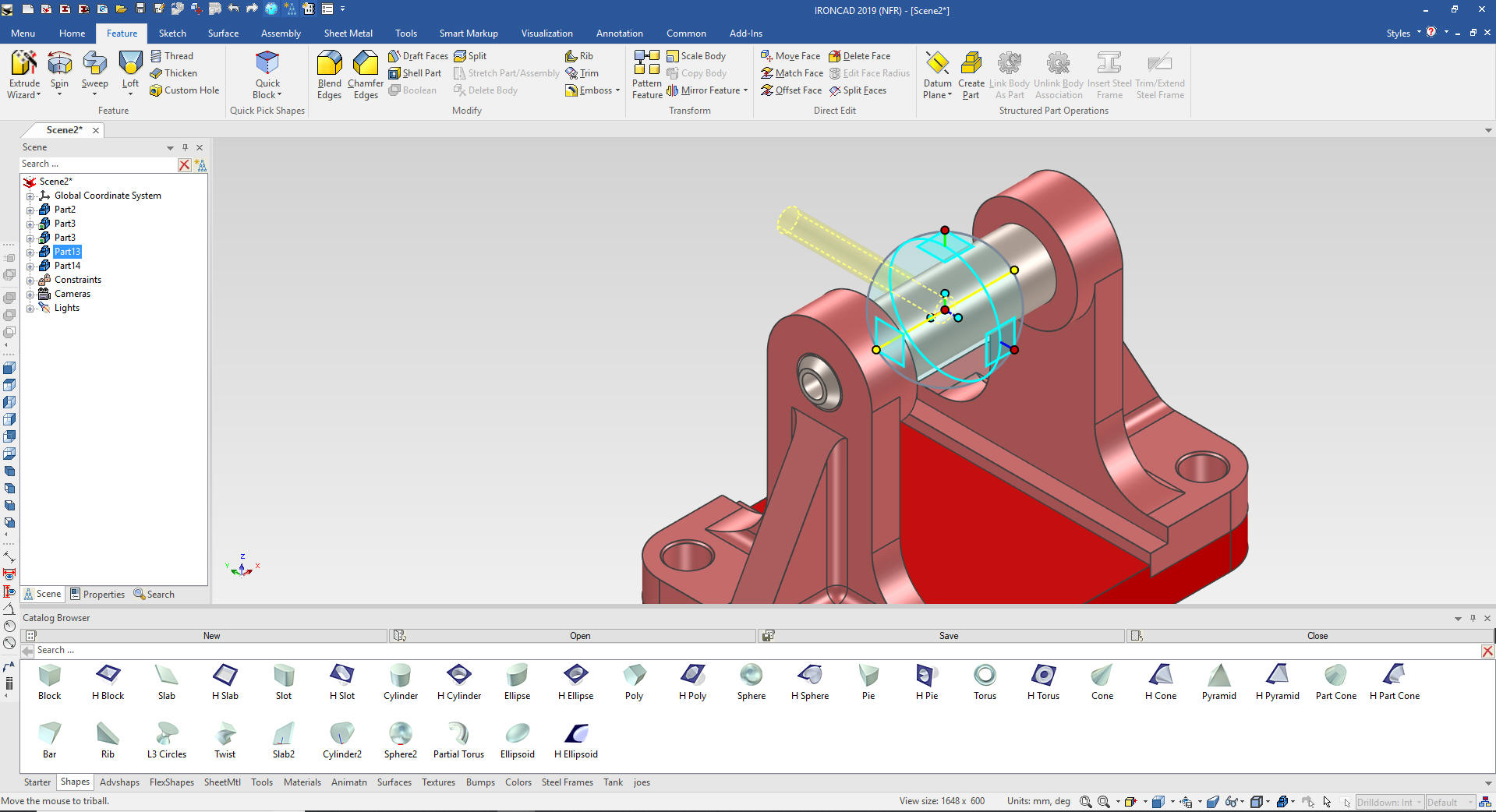

We

select okay and we locate the rib with the triball.

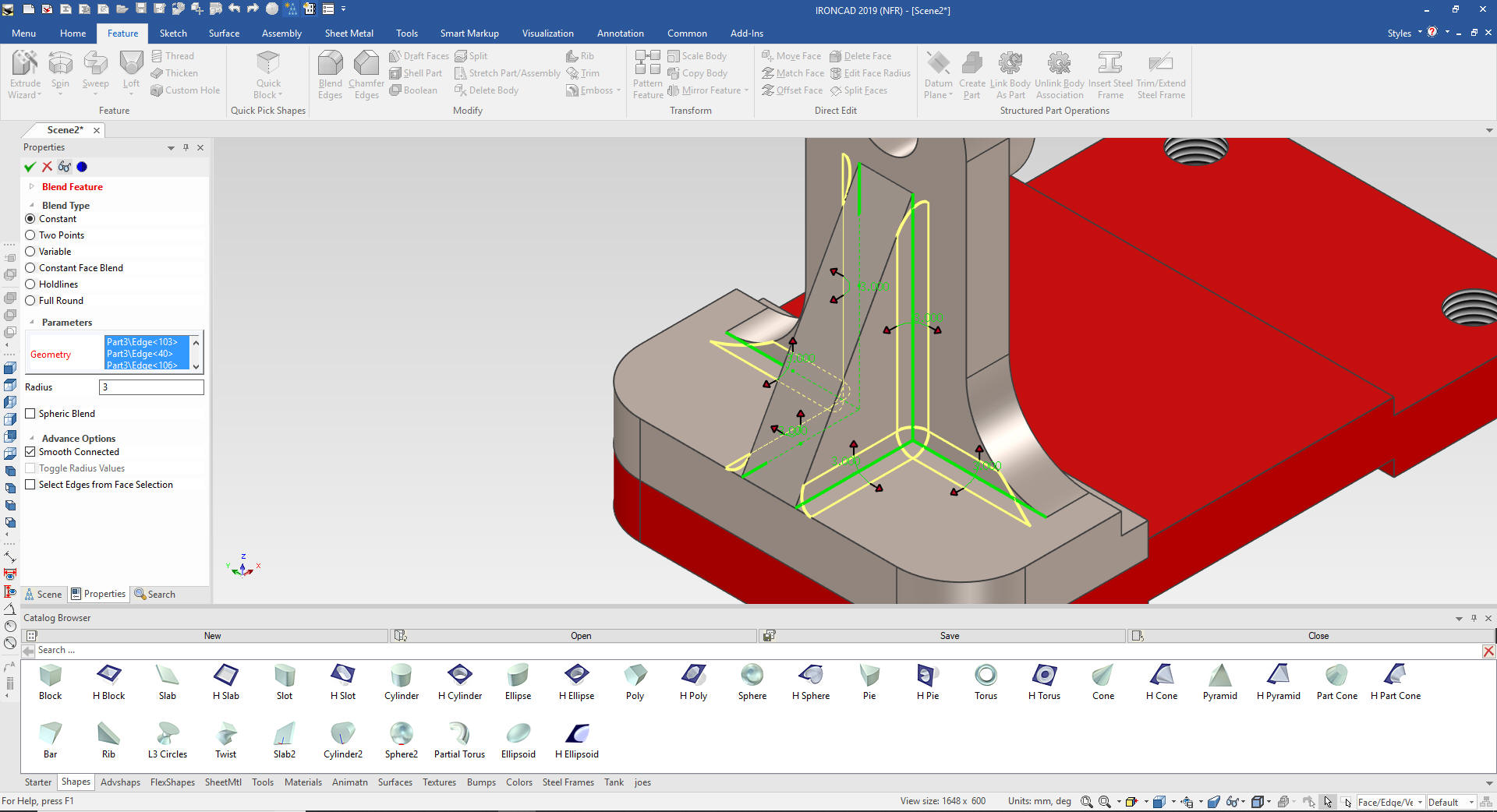

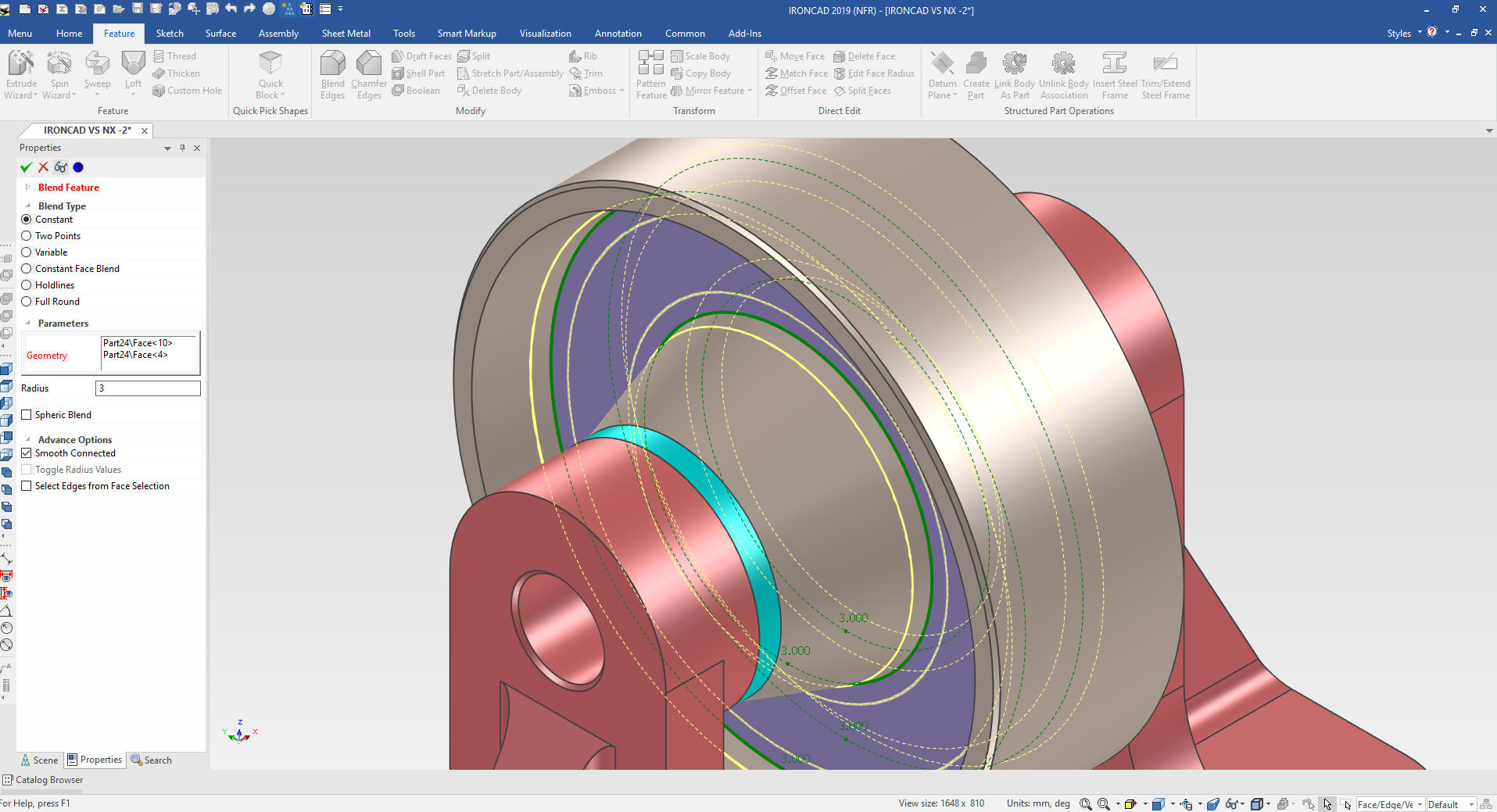

We now

put in the blends.

Now

for the holes.

I drop a 10mm hole on the top face of the

bracket face.

I

could have made these with the original projection but I want to

have them linked for use later.

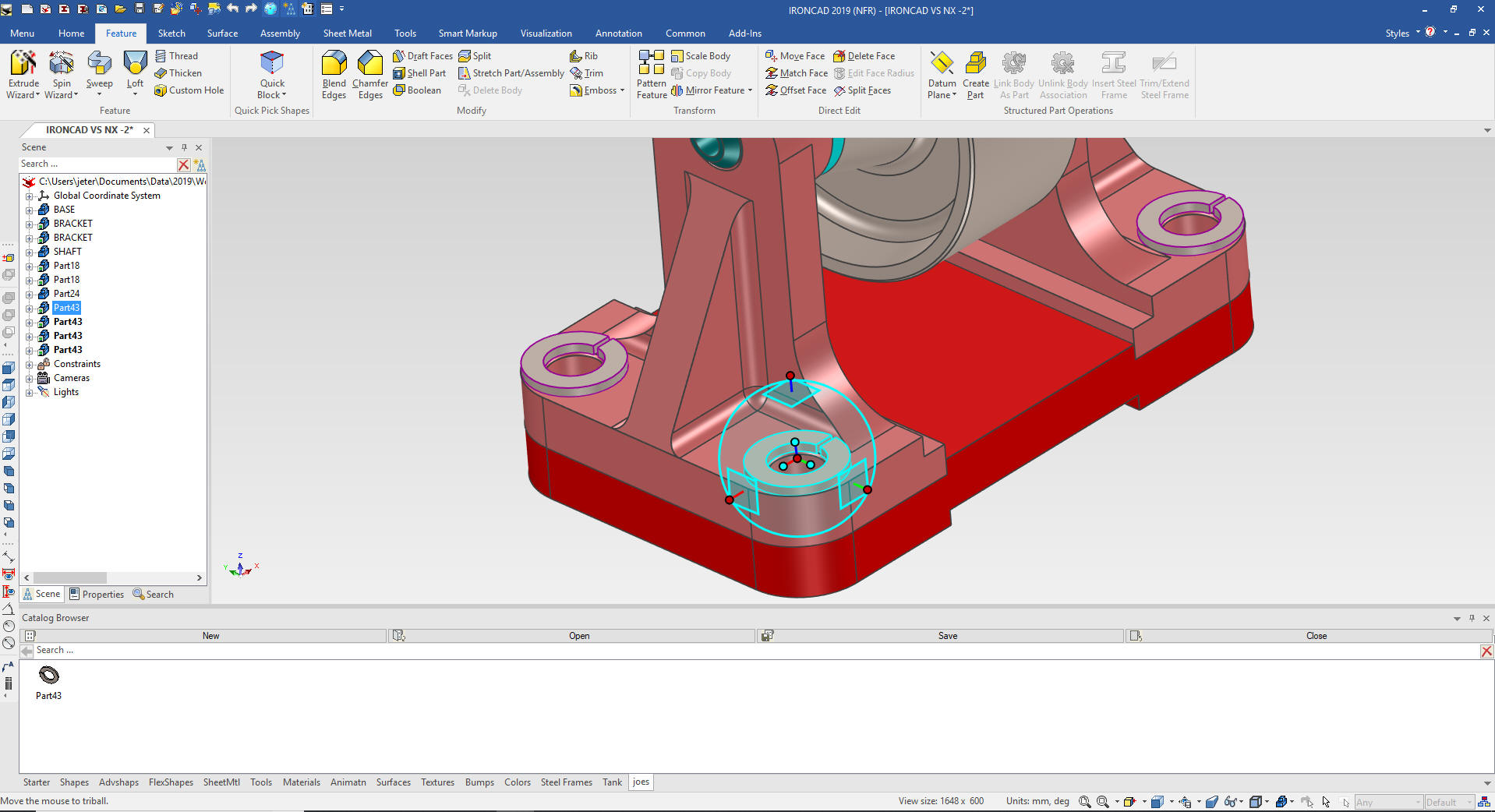

I will now turn on the

Triball, locking the feature to the plane will move it the center of

the base plates hole than use it again the same way to link it and

use the base plate hole to locate it.

Add

the chamfers and we are done.

We

will link rotate and locate the bracket at this time.

We

change the color of the bracket, since they are linked both change.

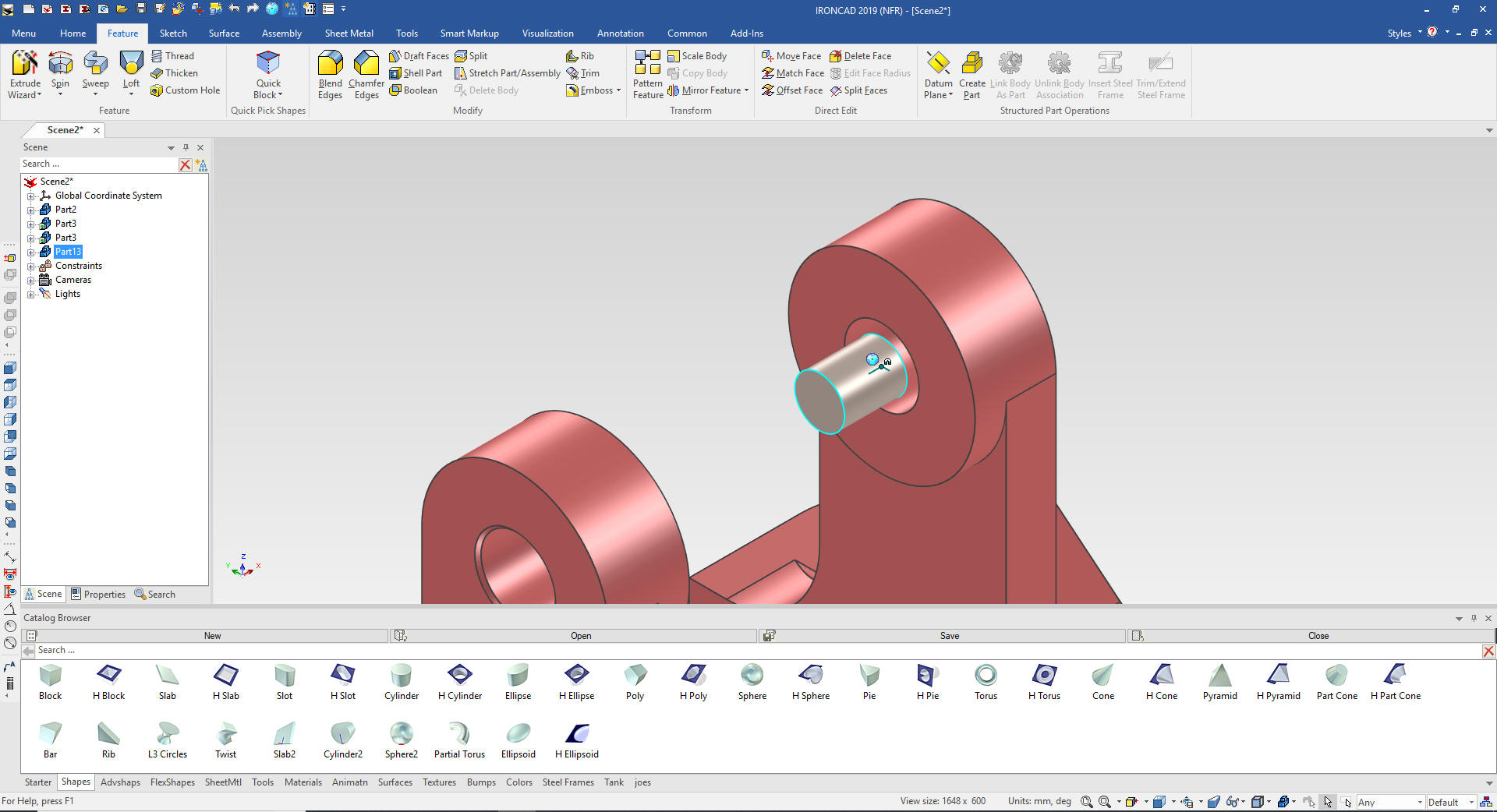

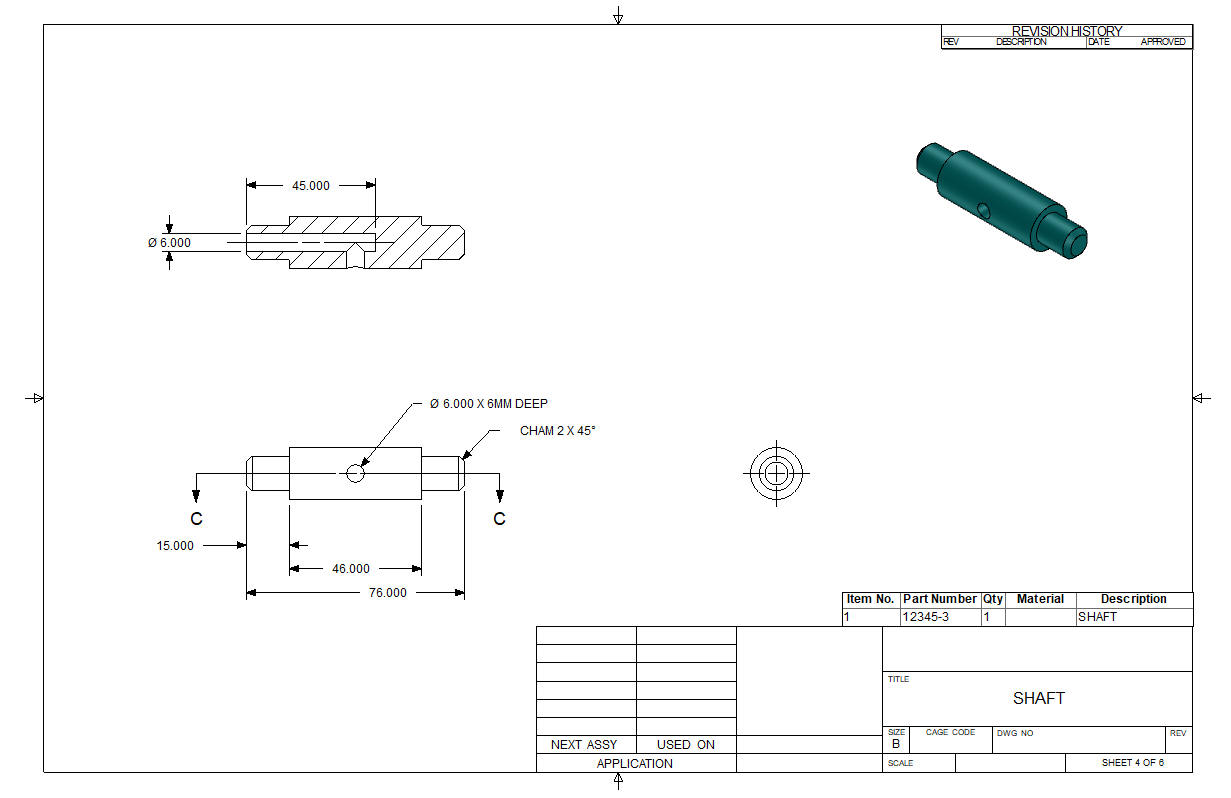

Now for the shaft. We drag and drop a cylinder to the front face

of the aft bracket

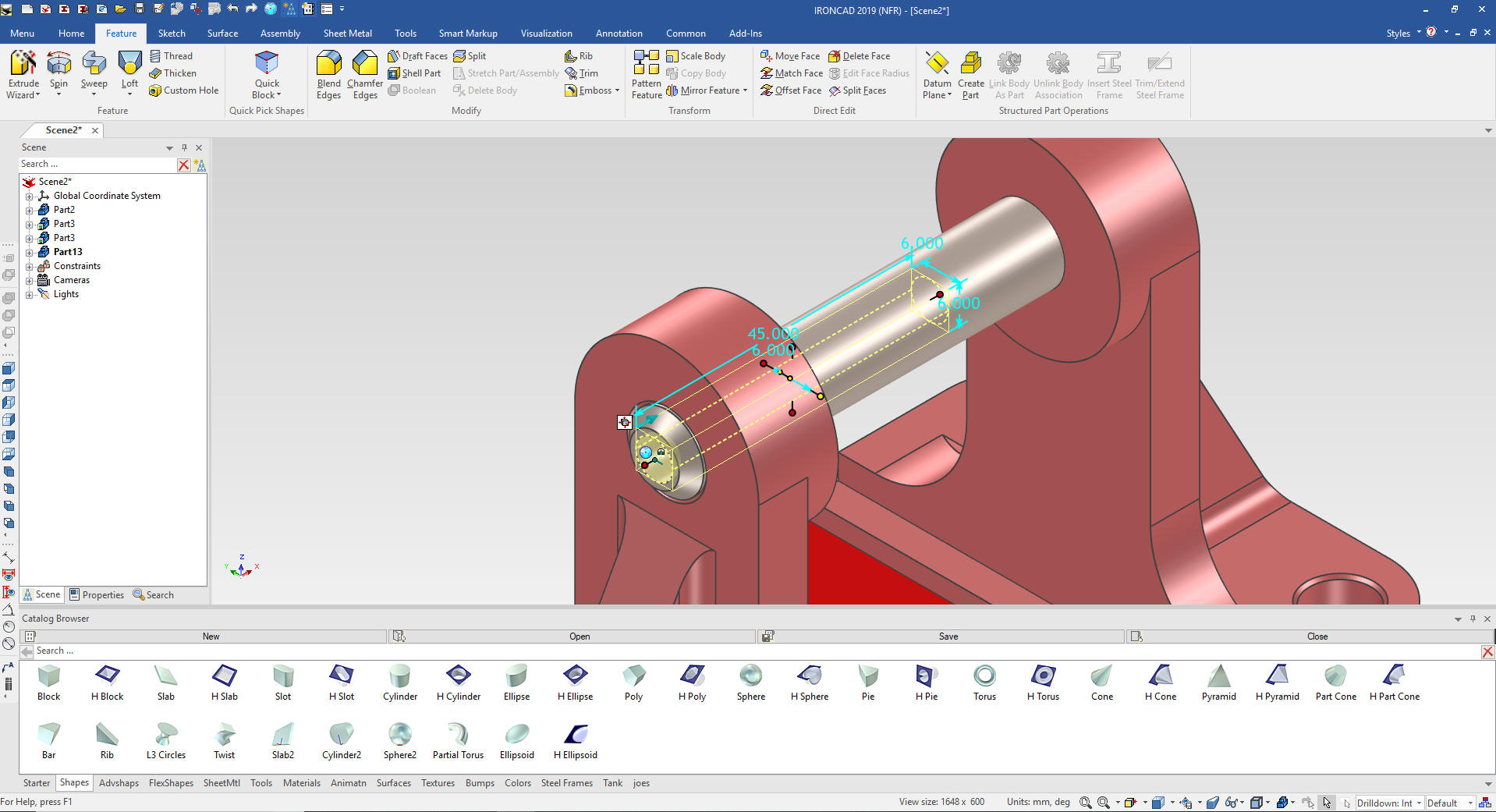

We

now size the long portion of the shaft. We size it, add the chamfers

and the hole.

Now

we drop another cylinder that will become the larger center portion

of the shaft.

We

just size it an pull it to the mating faces. Now for the hole I will

use a little trick. Since it is the same size as the end hole I can

just take the triball and rotate it 180 degrees and copy it and move

it. I could do this with any size hole.

We

now just size the length of the hole and we are done with the shaft.

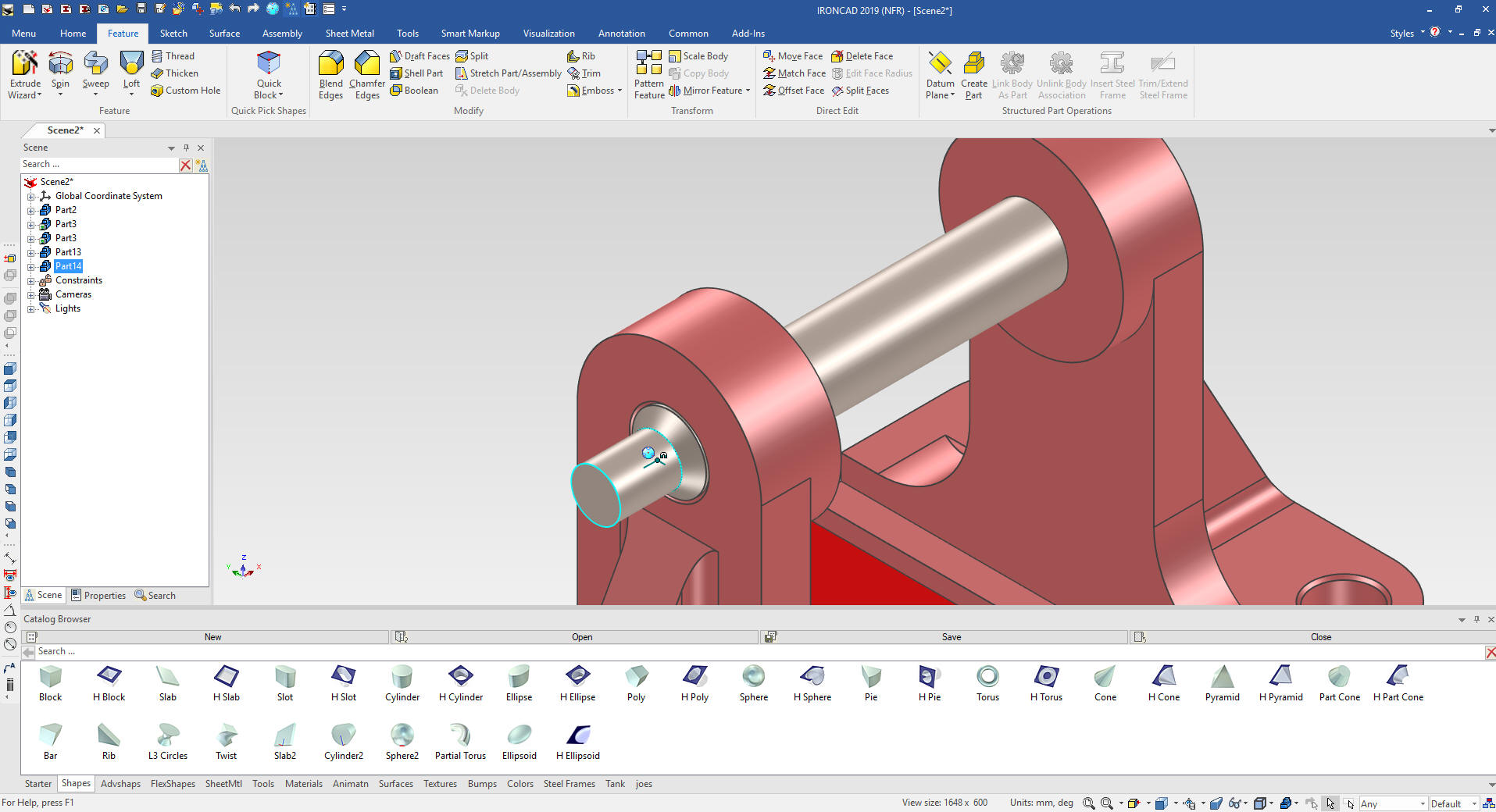

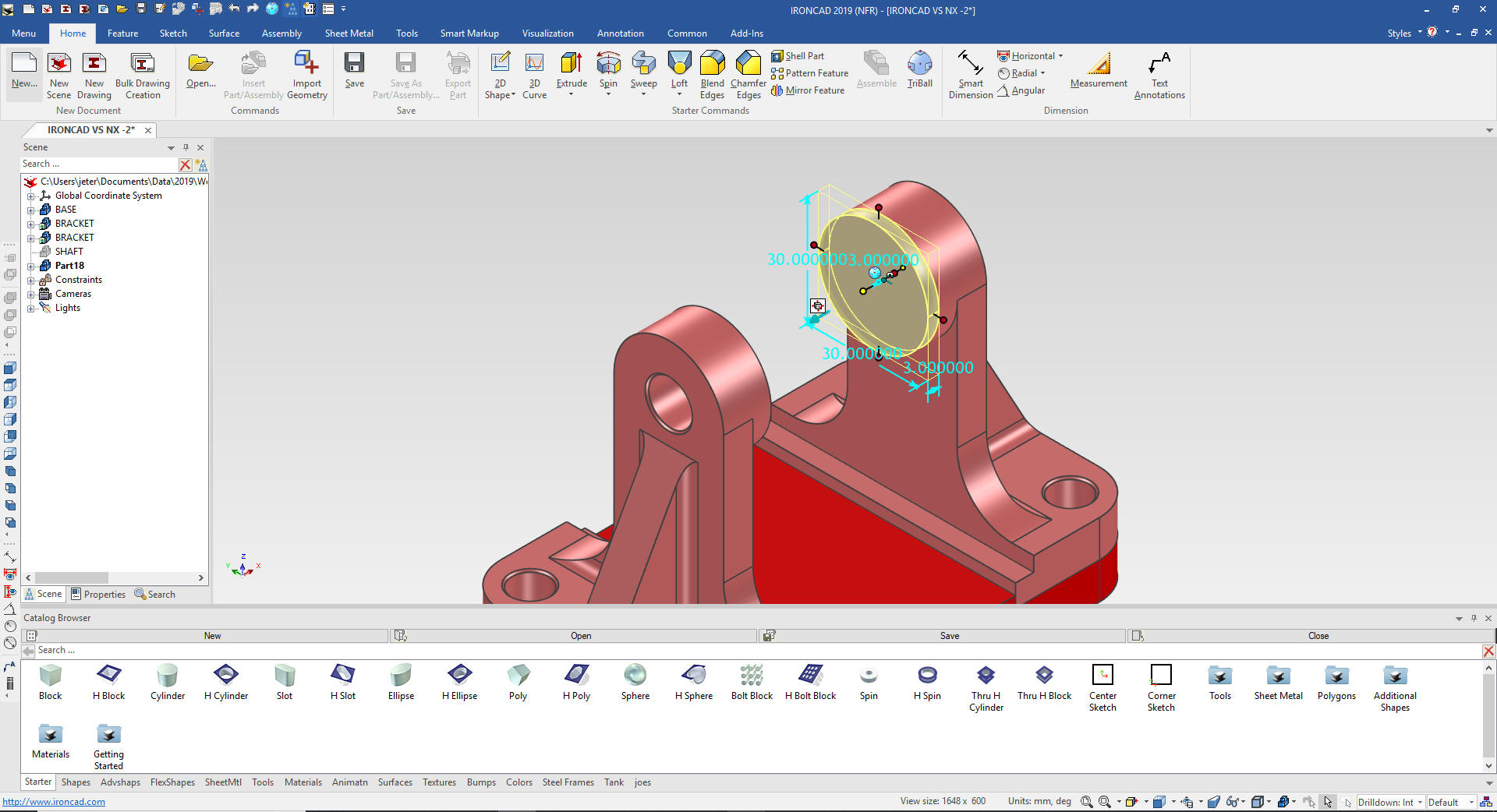

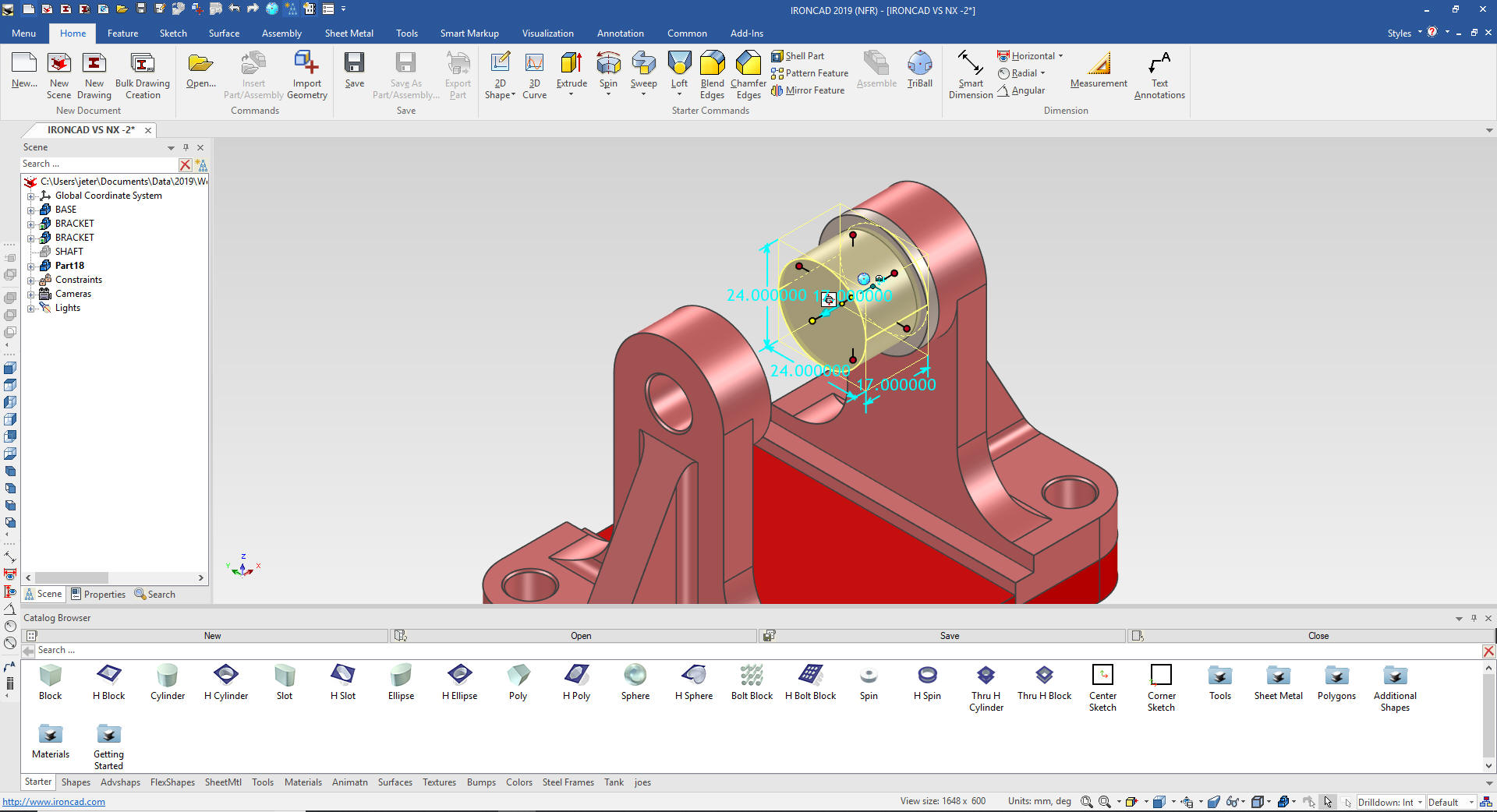

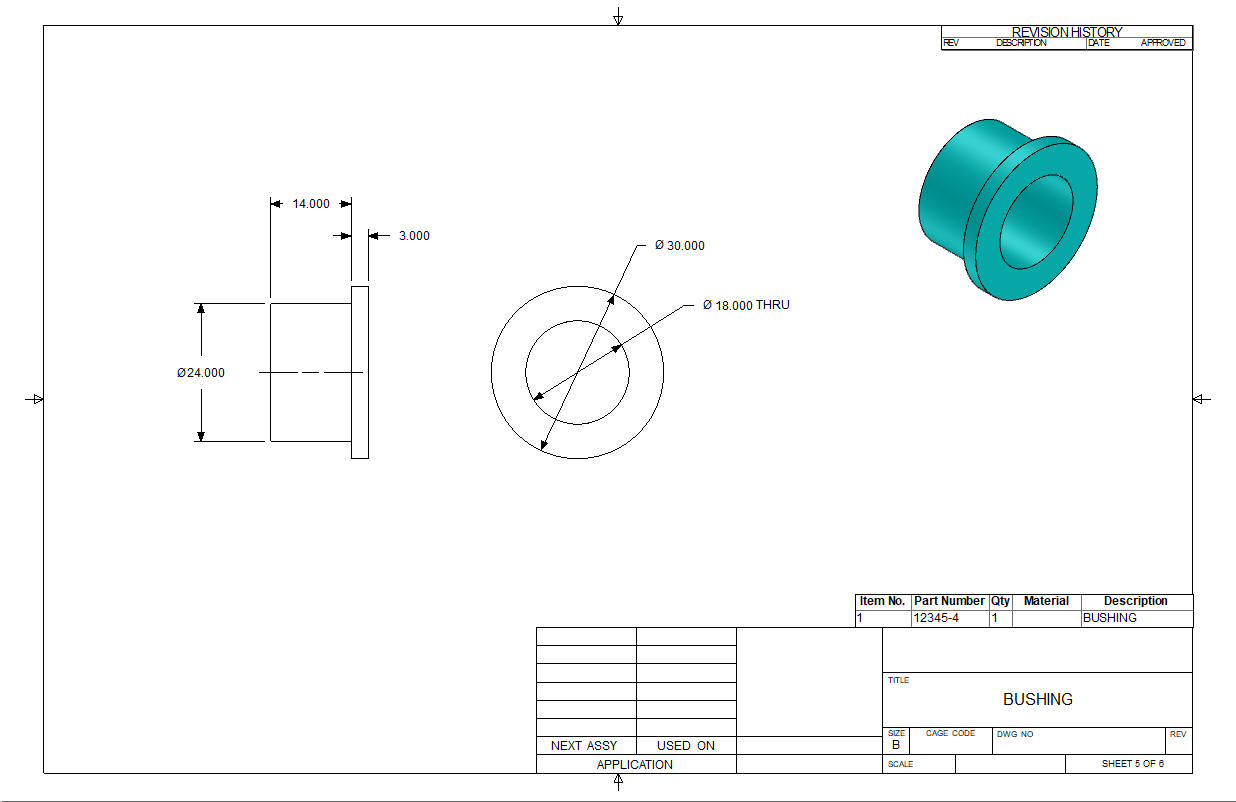

Now for the bushings. Notice I am not worried about assembly. We

will create the assemblies later.

We will hide the

shaft and drag and drop a new cylinder to the center of the boss!

Now just edit the size box. The size box is the basic envelope of

the Intellishape.

Now

we add another cylinder to the center and size it, but we will use

the left mouse button that automatically makes it part of the

bushing. I pull the aft handle to the aft edge of the original

cylinder and then set the 17mm length. That way I don't have to

worry about subtracting or adding.

Add

the hole and the chamfer and we are done with the bushing. We then

use the triball to link and rotate into place and change the color.

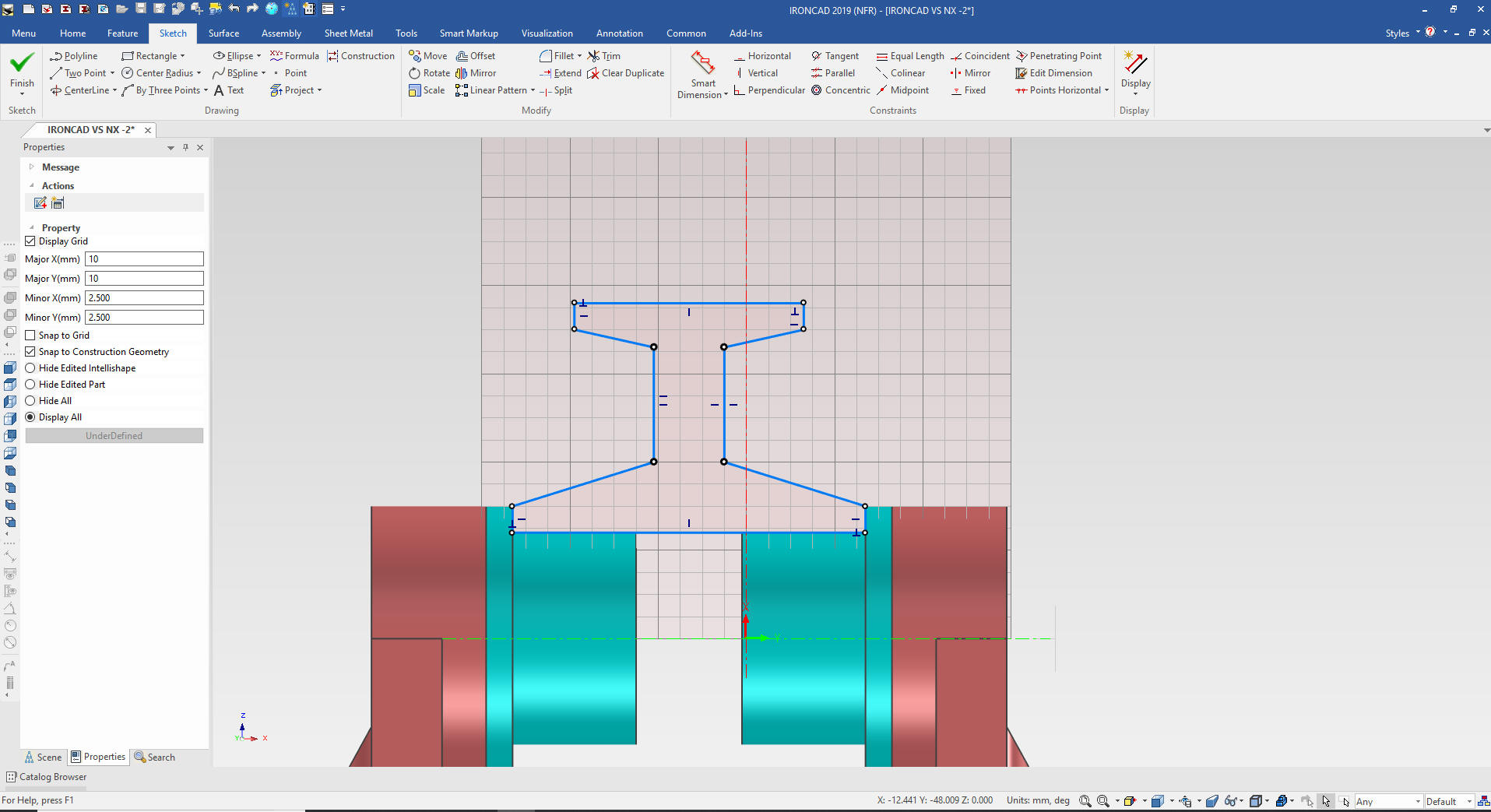

Using the Spin Wizard I locate a sketch and set to 360 degrees.

I

have created my reference entities. I will use StreamLined

Sketching! We can use constrained sketching but I have found like in

the Solid Edge presentation it is a bit more complex. Also I have hid the

catalog for more space in the scene.

Learning IronCAD! Lesson 3

Streamlined Sketching

(Unconstrained Sketching)

Why do we call it a Scene instead of a workspace? IronCAD was first released as Trispectives, a graphics design package.

Now we will add a few parallel lines.

Now

we connect the dots and delete the referenced graphics leaving the

reference centerline.

We

mirror the graphics and add the lines and delete any reference

entities.

We

select okay and add the chamfers and blends, by selecting the inside

face and we are done.

We

show the shaft and were are done done with our design. Now to add

the fasteners. We drag and drop the washer from a custom catalog

locate and link using the Triball.

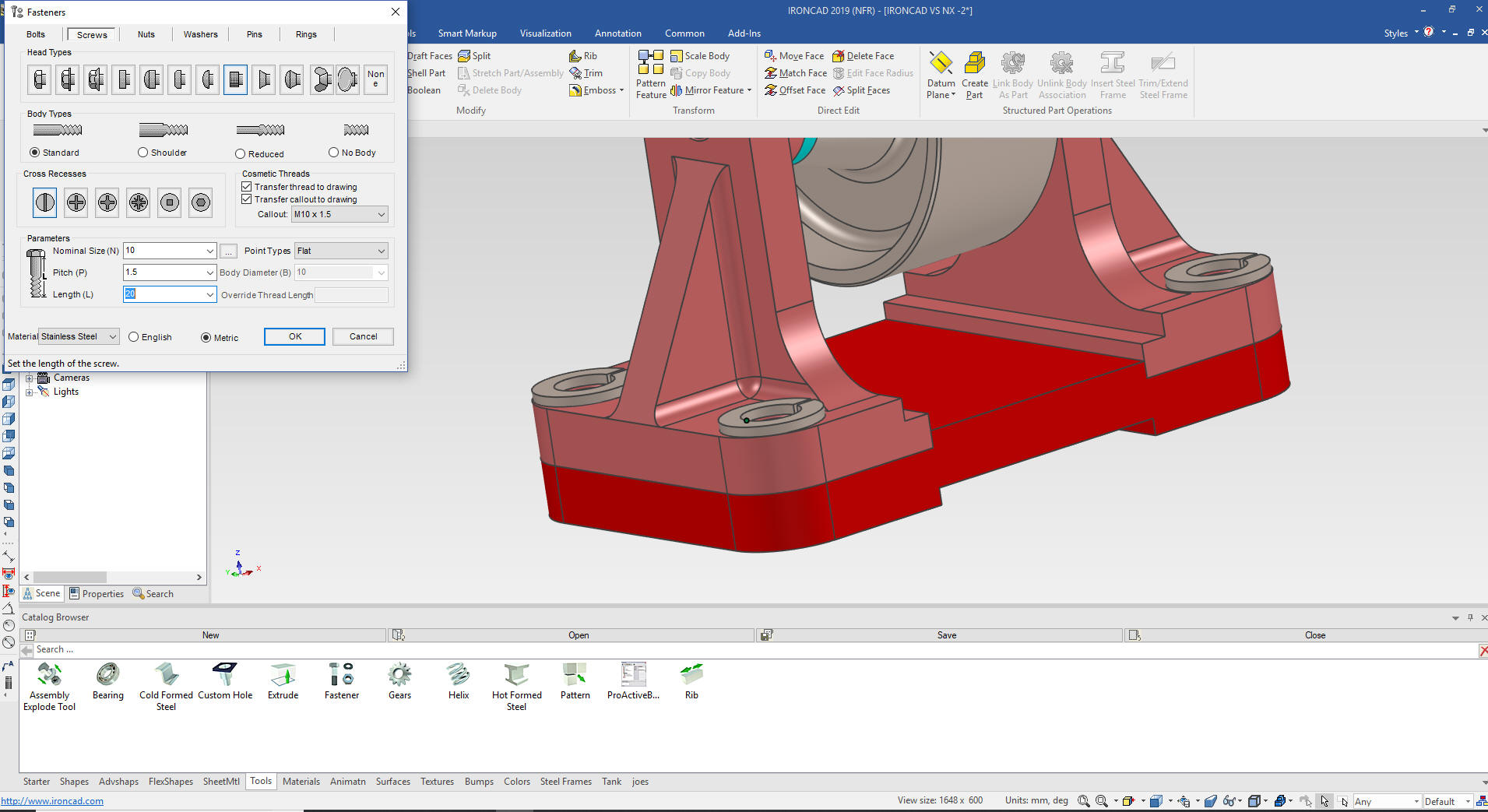

Now

for the screws screws. We drag and drop the screw from our fasteners

in the tool catalog and define it in the dialog box.

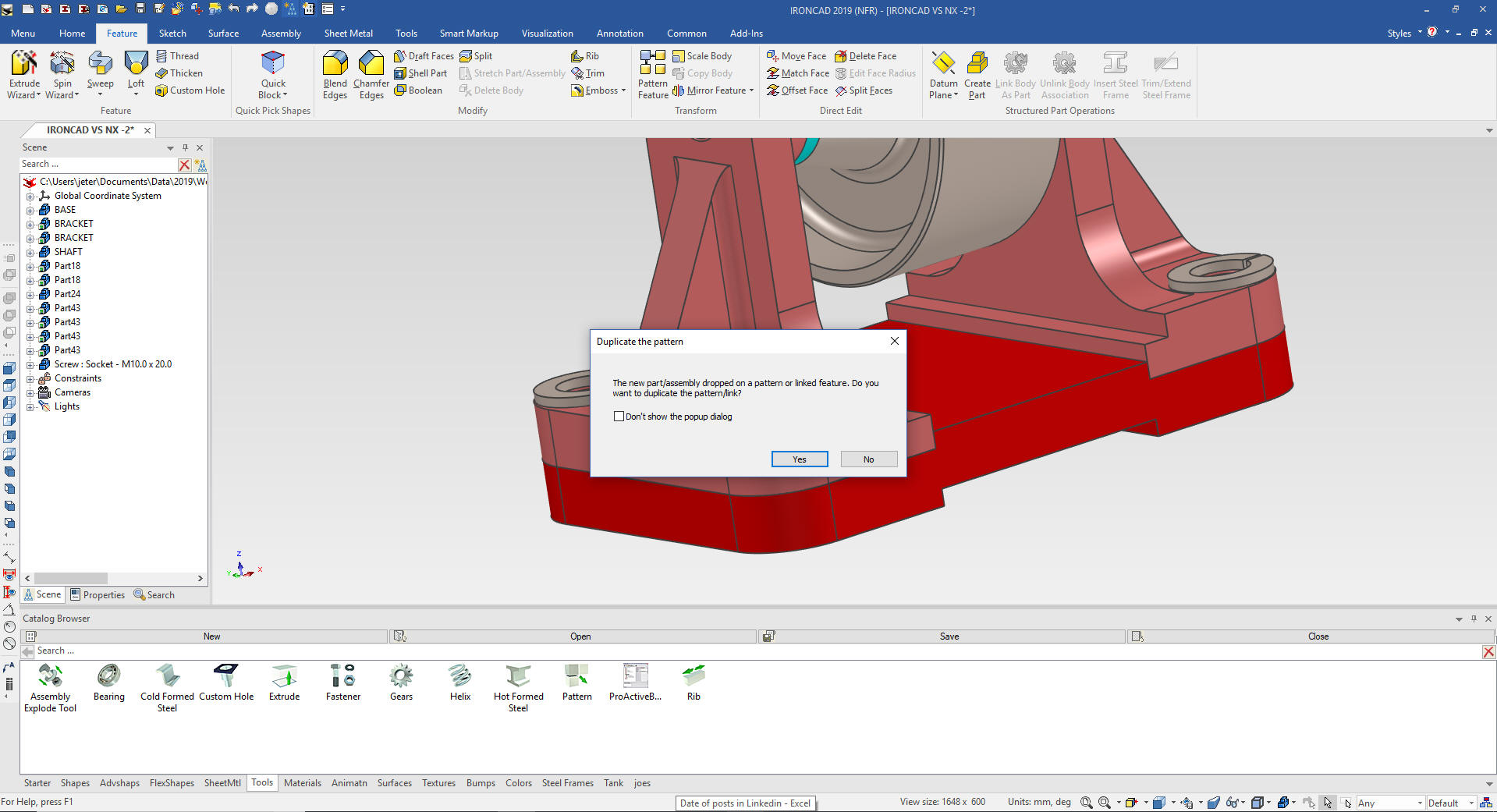

We

have the option to create a screw at all of the linked washers, we

select yes.

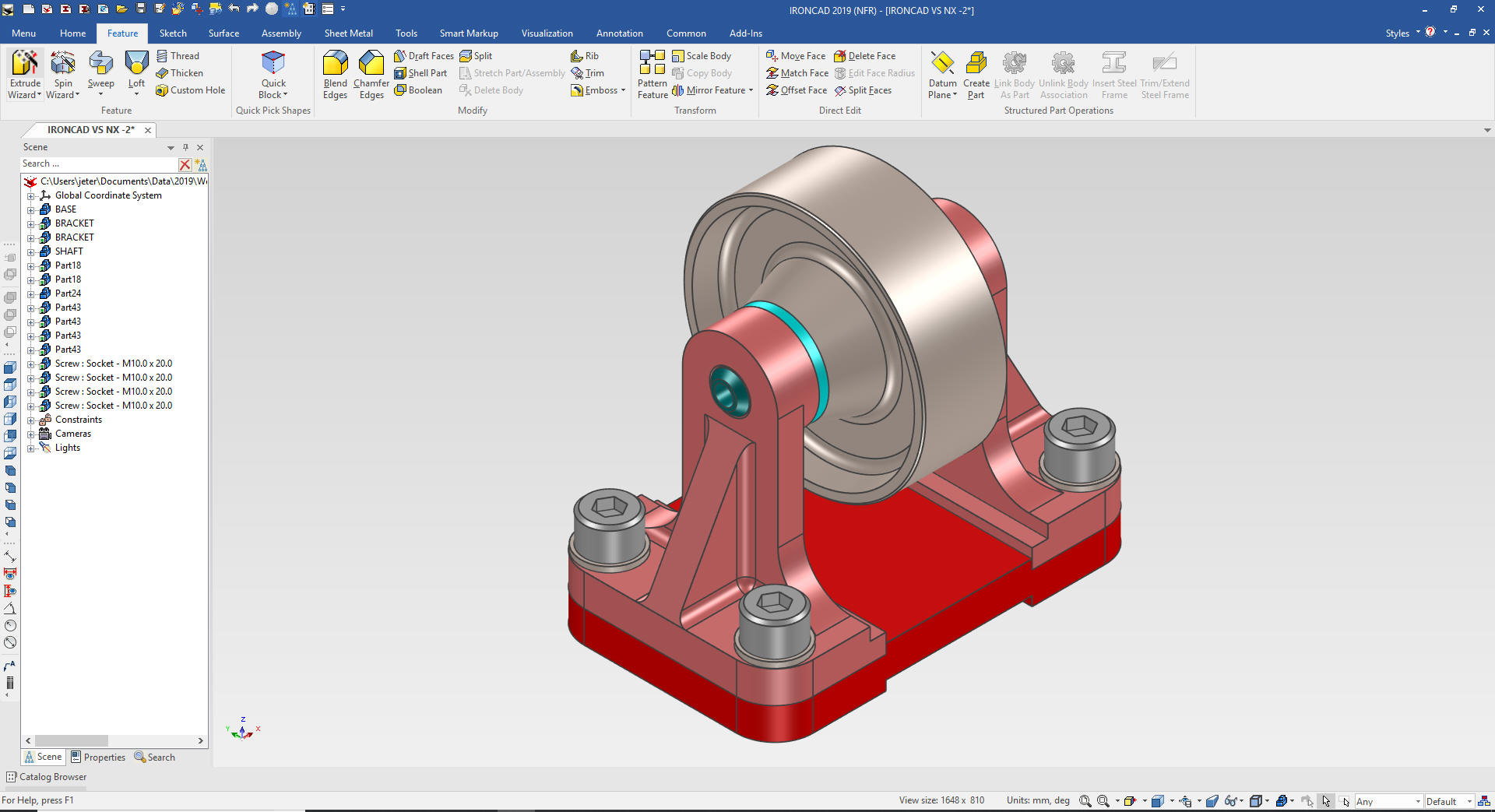

We

are now done with our assembly. All parts were designed top down and

in context in a single model environment.

Look through the

process again, these are all the steps to create this assembly.

Compare it to Solid Edge.

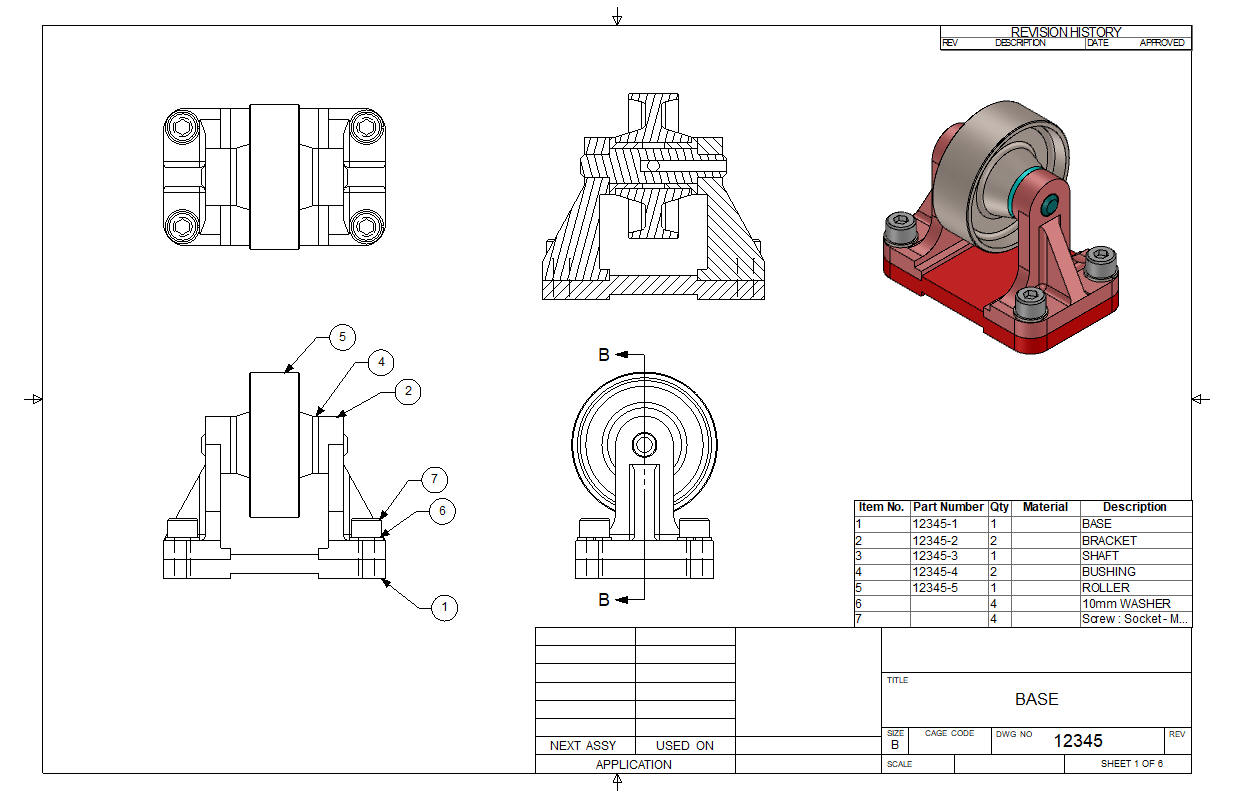

Making the drawings is a breeze. We just select the Bulk Drawing

creation, select the parts and IronCAD will generate the assembly

and the other 5 parts for detailing.

Think of the amount of

files created with Solid Edge the five parts and one assembly, if

you create the AIDs (Associated Information Documents (drawings))

that is a total of eleven files to maintain. IronCAD created two

files.

It is

very important that you look into how you or your engineers are

creating the parts. Streamline Sketching and Feature Based Modeling

is easy to learn and implement. It, alone, will increase

productivity 10X. Now, IronCAD with its unique integrated

history/direct edit functionality can increase your productivity

another 5X or more with changes! Again, time is money in

engineering.

More on Streamline Sketching and Feature

Based Modeling.

3D CAD Modeling Techniques

To experience this increased level of productivity, please download

IronCAD for a 30 day evaluation. Legacy data is no problem, IronCAD

can read the native files of all of the popular programs. IronCAD is

a great replacement for the subscription only Autodesk and PTC

products.

Give me a call if you have any

questions. I can set up a skype or gotomeeting to show this part

or answer any of your questions on the operation of IronCAD. It

truly is the very best conceptual 3D CAD system.

TECH-NET Engineering Services! | |