|

Engineering Ignorance Defined IV Defining the “2D Drawing” Redundant? Of course! Educating the PLM Guru!  | |||

Engineering Ignorance Defined CONFUSED? MBE - Model Based Enterprise MBD - Model Based Definition Engineering Ignorance Defined II Top 5 Reasons to Use MBD DEBUNKED! Engineering Ignorance Defined III How to Define a 3D PMI Assembly You have got to be Kidding Engineering Ignorance Defined V Altering the Model for PMI Documentation There are two very ignorant terms that have entered our lexicon. I don't know which is worse "2D Drawing" or "BOM" August 15th, 2019 I found the culprit that first started using "BOM" It is heavily referenced in Frank B. Watts "Engineering Document Control Handbook". I started questioning myself. So I looked in my 1981 DRM (Drawing Requirements Manual) which is available on Amazon and there was no reference to BOM just PL. Frank was an old timer engineer spending most of his time at Caterpillar, I read this in Linkedin, but his profile has disappeared. I am sure it wasn't spent in Document Control since that was a separate department under engineering in those days. Here is a statement from his book. You can see the circular logic. As I read through the book I really can't come to any logical conclusion or reference why he would use Bill of Materials.

Parts List and BOM

If a BOM is a compilation of

parts lists, it follows that:

Definition:

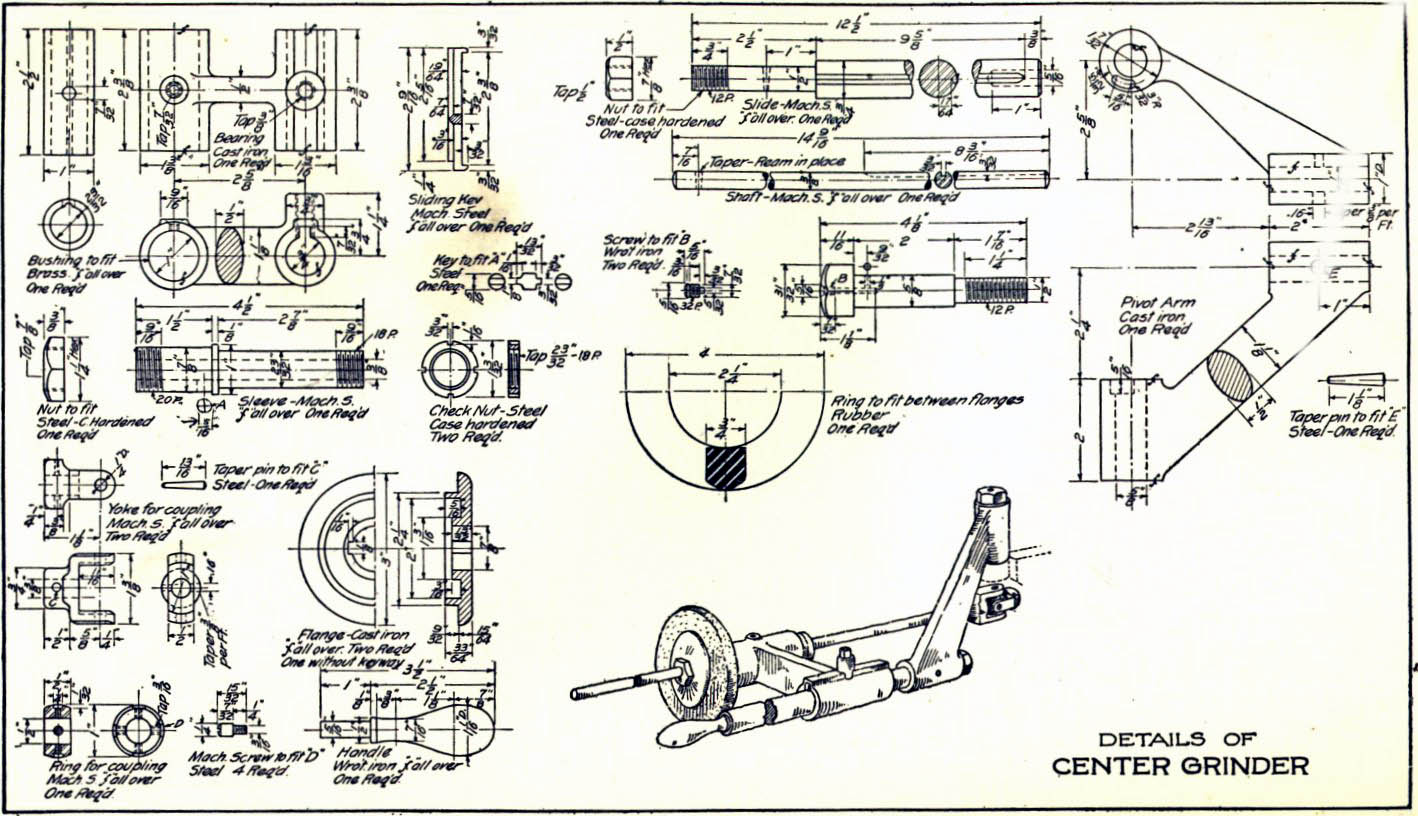

A parts list is a single level BOM I have had some new realizations about Part List vs BOM. I will tell you it is very hard to step out of a knowledge box and into an ignorance box. Throughout my career (54 years) I have never seen or used "Bill of Materials" as the title of a parts list. I was a contract design draftsman (Jobshopper) most of my career continuing to support the industry as a PC Based 3D CAD dealer mostly supporting Boeing and their suppliers. I have worked at many different manufacturing companies and not one called the parts list a BOM. Part List or BOM? Below is a format from CADKEY that was included with the system in 1986. It still is used today. We can all agree that engineering is not manufacturing. When the design and documentation is done it is sent to document control to be archived. I am not sure what they do now... LOL I know it is a mess. The Space Between Engineering and Manufacturing From there it moves into manufacturing. Usually into planning, which is in charge of manufacturing, that sets up the process to manufacture the parts and the installation or assembly. Now planning will set up the purchasing requirements. Parts are not materials. They are made up of materials. Now the words "Parts List" do not have to be defined. But let’s take a look at the word "Bill". "an amount of money owed for goods supplied or services rendered, set out in a printed or written statement of charges." So, a "Bill of Materials" is a purchasing document. This may have caused a misunderstanding of the use of the Parts List. A parts list is only use in the defining what makes up an assembly and has no other significance. You could see how the PLM gurus could misunderstand this. One fellow has a 3rd party add on called "OpenBOM". Being a PLM guru, I think that he has confused a part list which has no reference to purchasing to "Bill of Materials" that implies purchasing. Makes you wonder how many others have? Purchasing in a company is not part of engineering. Purchasing is a good resource for the status of a part? In this article we are only focused on the industrial/mechanical engineering industry and how as it relates to engineering documentation. Defining the "2D Drawing" Okay, if "3D drawing" was in our lexicon this would a functional term. But there is no "3D Drawing". I suppose you could call the idiotic PMI a 3D drawing, but we missed that bullet. Of course there could be no "3D drawing".. how silly is that? A drawing by its nature is only 2D. So you can see why I roll my eyes when these most learned PLM gurus use it. I have to listen to seasoned engineering professionals use it and trust me the millennial engineers have no clue. When I went into work at Boeing as a young draftsman in 1965, what did I do. No, I never said, "Now I am going to create a "2D drawing"" I mean really, how stupid is that? So what is a drawing? drawing Noun 1. a picture or diagram made with a pencil, pen, or crayon rather than paint, especially one drawn in monochrome. mechanical drawing Noun a drawing to scale of a machine, machine component, architectural plan, etc, from which dimensions can be taken for manufacture We can add a bit of description here as it relates to engineering mechanical drawings. Views of the part defined by "unassociated" orthographically projected views. Manual Mechanical Drawing done on a "drafting board" This is a detailed assembly. It is a bit tough to find a manual drawing on line. They basically disappeared in the mid-1980's with the introduction of the electronic drawing and 3D CAD packages. Years before the internet and PDFs.  Electronic Drawing done in AutoCAD. Autocad was introduced to the PC in 1983. Most of the large companies bypassed the electronic drawing packages and moved directly to 3D CAD. I don't like calling these packages 2D since they create drawings, again by their nature can only be 2D. Sadly, this was a poorly designed architectural package and had no copy protection. It was widely copied. Imagine the smaller companies at the time facing replacing each drafting board with a $4000.00 CAD system. Yes, even a free architectural based electronic drawing package was more productive than the manual mechanical engineering drawings. Only one that has manually erased and moved a complete view could really understand that. Actually I completely missed the electronic drawing phase! That is it. Those are drawings, only drawings, no not 2D drawings. So if you read this and you use "2D drawing" again, I am coming after ya! LOL.. We do not make drawings anymore! Hey, wait a minute what are you talking about all of the CAD systems have drawing modules to do the drawings!!!! Enter 3D!!! So do we create drawings as described above? Of course not, in the drawing or better called the "documentation" or "AID" module we create views generated from the solid model. Then we add the dimensions and annotation. We are surely not creating drawings. Well, they look like drawings!!! Yes they do and that is where the problem starts. AID (Associated Information Document) This is what I have coined these 3D CAD generated documents. At Boeing they were called the "Flat Files". They called them the flat file because they were plotted and handled just like the drawing. They were delivered to the suppliers in the form of prints until the wide release of the PDF at the turn of the century. There are two AIDs: A "Part AID" travels with the 3D model thus associated. An "Assembly AID" even though it is associated to the 3D model should stand alone. Due to proprietary concerns, you should never deliver the 3D assembly to a vendor. Unless of course they are responsible for the complete fabrication of the assembly! Here is the solid model of the above AutoCAD drawing. It took less than an hour. The productivity of 3D modeling cannot be denied. Now, I am sure designing it from scratch would take a bit longer. IronCAD is the king of fabrication design with its single model environment and drag and drop design from standard and custom catalogs. Now here is the "Assembly AID" generated in IronCAD's documentation module. This just took less than a half hour to layout. No, I didn't "DRAW" one line or arc. These do not meet the definition of a drawing. So we have to quit using the "2D Drawing" to defined this documents. Here is a fellow that is in charge of Solidworks MBE efforts that has no understanding of this concept. Why? Because they make no difference between a drawing and an AID. Please remember, Solidworks, like all Pro/e (Creo) clones have been creating AIDs, from the beginning. In fact they have no "drawing" capabilities. IronCAD includes a Autocad clone and ZW3D offers basic drawing funtionality in their "2D Sheet". Engineering Ignorance Defined So, again I say we do not make drawings any more. Yes, there are places where drawings are viable, schematics, like seating or floor panel diagrams. Even fabrication from standard materials is okay, like the Autocad drawing above where the parts are not going to be used for CNC or 3D printing. But making ISO views are very time consuming manually or electronic drawings. PMI (Product Manufacturing Information) I am not going into PMI much here. But I want all to know it was only created because the PLM Gurus found trying to synchronize the model and AID almost impossible. They needed one document to maintain and the completely unworkable PMI was developed for the basis of the MBE mess. There is no debate on the which is more viable, the Model and AID or the PMI, There is only one reason "Cost". A model and AID need a compatible CAD system and an Adobe Reader. What is required to read a PMI? They are native files and there is no standard free viewer or translator. There is no reason for a viewer, there are no dimension to view. It is basically worthless. It is a very inaccessible and expensive format. The PMI offers nothing over the AID for documentation and is still delivered by email! It makes the customer totally dependent on the CAD system. Huge Point: The 3D model and the AID as a PDF travel together! The AID is not made to be a standalone document and should reference the 3D model. That is one of the reasons it does not have to meet the strict standards of a drawing. Why MBE/MBD/PMI Will FAIL Why MBE/MBD/PMI Will FAIL Part II In the following article we show an actual industry released PMI. It is not a pretty picture, nothing like the simple examples. It truly is a chaotic mess. There are no standards so anything goes. At least this company has one document. Boeing PMIs are three or four documents, quite clueless. Just to replace the simple drawing and now the even simpler AID. There truly is no debate. PMI vs AID This is how out of control the PMI is, there are virtually no industry standards. Here is a bit of training on dimensioning and the failure and complexity of the PMI. Conclusion Be aware as you used these two terms, "drawing" or "AID". Realize which format you are talking about. They are two completely different animals. Educating the PLM Guru In this article I will try to educate the PLM/MBE/MBD folks. There seems to be an over abundance of PHDs and MSMEs in this field and not one have any engineering, design or documentation experience. I have talked to a few PHDs and I wonder if they can even learn anything. LOL! It is funny, with all my years in engineering I never met one MSME or PHD in the drafting room. I only pick on them because they use "2D Drawing" through out their comments and have no idea how they are create or how they are used. How can this be? Documentation is the only product of engineering! What the hell does PDM and PLM deliver? I know what documentation control delivered in the past.

How could have these geniuses overlooked this? I have written article focused on the PLM Gurus ignorance of engineering documentation. Engineering Documentation - A Primer for the PLM Guru! The Death of PLM Standard Cloud Based Engineering Document Control Standard Cloud Based Engineering Document Control Part II I use the following article as an example of how using the generic "2D Drawing" or even 2D CAD can be confusing. I even wonder if the author understands the use of these words. The MBD/MBE discussion Jos referenced me as "Famous for my opposition to MBD". "Famous"? The first I have heard of it, but I appreciate it. But it is just one of the things I am opposed to in today's world of 3D CAD. The 2000's - The Age of 3D CAD Un-Enlightenment! Jos Voskuil is a self-proclaimed PLM expert. No, that is not an insult, because all PLM experts are self-proclaimed. It is impossible to be anything else but a "self-proclaimed" expert because it cannot be standardized. There is not a MSPLM degree, at least yet. Jos is one of the more prolific PLM experts along with Oleg Shilovitsky and Chad Jackson. All have no engineering design or documentation experience. All have worked for PTC or a another major Pro/e clone CAD vendor and should have known the difference between a drawing and an AID. I do think Jos has a bit more applicable experience with engineering documentation. Let's take a look at his linkedin profile. These are an incredible insights to a persons capabilities and knowledge. It is funny, not one PLM Guru has any experience in engineering documentation. His education is not in engineering. His first job listed was: Manager Data Management Group Greenock BV May 1991 – Aug 1999 - 8 yrs 4 mos During my period in Greenock I was responsible for the data management group - 13 people. Our main target was providing our CAD customers (mainly AutoCAD / SolidWorks) with data management solutions (doc management / engineering database / PDM was emerging). Here it built the expertise working with BaaN PDM (Manta), SmarTeam and Cyco products Greenock is still in business as a Autodesk Dealer. Looks like they don't currently support Solidworks. This job intrigued me. You can see he had to work with Autocad .dwg drawing files for at least 4 years and then he may have been introduced to Solidworks in 1995. This bothers me a bit, if he managed data, surely he should have known the documentation out of Solidworks was an AID (Associated Information Document) and there were no drawing capabilities. How could he possibly had missed the reason 3D CAD was created: "Faster Documentation" All documentation then was delivered as prints generated by a plotter or large printer. HPGL, the language that became the standard that drove the plotter was actually used as a translation vehicle and could be read by many system including MS word. The 1980's - 3D CAD - The Beginning We sold large format plotters to the industry for years until the introduction of .jpg (yes they were used) then the much more functional and widely available PDF. I want you to look at this article from his blog. Model-Based – Connecting Engineering and Manufacturing Here is one of his comments. "Historically designs were done on the drawing board in 2D. After the introduction of 2D CAD and later affordable 3D CAD systems at the end of the previous century, companies made a shift from designing in 2D towards 3D. The advantages were clear. A much better understanding of products. Reading a 2D drawing requires special skills and sometimes they were not unambiguous. Therefore, 3D CAD models lead to increased efficiency and quality combined with the potential to reuse and standardize parts or sub-assemblies in a design." There are others but this exposed his lack of understand of engineering documentation today. "After the introduction of 2D CAD and later affordable 3D CAD systems at the end of the previous century, companies made a shift from designing in 2D towards 3D." Actually 3D CAD was adopted before the electronic drawing packages (no, I will no call them 2D) Boeing never used the electronic drawing except for facilities. I was in the 747 Flight Deck group in 1986, everything was being done on the drawing board except for three Catia 3 stations. They did have a seat of the mini-mainframe Computervision CADDS 3. Catia ran on IBM and is the only reason Boeing settled on it. The 1980's - 3D CAD - The Beginning While I was at Boeing I was introduced to PC based 3D CADKEY. Soon every design engineer and draftsman had a seat. 45 CADKEY and 2 seats of Catia 3. Boeing had 1500 seats of CADKEY. Sadly, Boeing Computer Services in cahoots with Dassault settle on Catia. The 1990's - 3D CAD/CAM Moves to the PC!! Autocad and 3D CADKEY were the only widely used PC based CAD systems. But CAD meant something totally different to each package. Autocad was Computer Aided Drafting CAKEY was Computer Aided Design Solidworks, a poorly designed Pro/e (Creo) clone was hardly the first introduction of solid modeling. Fastsolids, a 3rd party program that ran inside CADKEY and Trispectives (now IronCAD) were based on the ACIS solid modeling and introduced in 1995. Solidworks was released with the Parasolid solid modeling kernel. CADKEY or Catia? Boeing’s Billion-Dollar 3D CAD Mistake! This was one of the weakness of PLM, they didn't look for a more viable CAD solution, but standardized on the Pro/e (Creo) paradigm and were instrumental in locking the industry into this dated CAD paradigm. Sadly, the PLM folks were financed by the vested interests of the major CAD systems. "The advantages were clear. A much better understanding of products. Reading a 2D drawing requires special skills and sometimes they were not unambiguous". This statement could only be stated by someone that never made a drawing or AID and is relating to his own lack of skills. Drafting was in charge of the documentation. Many eyes were on the documentation before it was releases. Checking was a separate procedure. But the big question to Jos is what does he mean by "2D drawing". Is he aware the documents that come out of Solidworks are not drawings and very simple to create? Or does he think that they are "drawn", since there is no drawing module in Solidworks it would be quite impossible. Again I state "Engineering's only purpose is to deliver concise, complete and unambiguous documenting to manufacturing." Reading a drawing is a requirement for engineering professionals. If you cannot read a drawing you do not belong in engineering. And now most AIDs include an ISO (Isometric) View for a visual aid for the engineering impaired. If you do not have a 3D mindset, 3D CAD could be very difficult for design. "Therefore, 3D CAD models lead to increased efficiency and quality combined with the potential to reuse and standardize parts or sub-assemblies in a design." Now this statement is totally correct. I have been using 3D CAD from the very beginning. I have never made an electronic drawing. But the faster "Flat File" or AID generation was the selling point of 3D CAD in the beginning since there was virtually no other use for the 3D model. It is shocking that these PLM gurus did not even study the document controls system of the past. It would have given a much different insight on the process and would have put less dependence on the CAD system itself. Just missing this important fact, makes his article based on incorrect information. But then if you look at Jos's, Oleg's and Chad's profile you can see they have worked directly for one or more of the major CAD companies that have a vested interest in keeping the customer dependent on their PLM system. PLM is more important to today's CAD vendors than the CAD modeling! There is this young millennial engineer. I was debating him on manufacturing knowledge of engineers and draftsman prior to the turn of the century. I looked at his profile and realized he graduated in 2006. I am sure he never talked to a professional draftsman that he is now replacing. But I wonder about Jos, he was involved in 1992, CAD was completely in the realm of the draftsman until 2000. He must have talked to at least one draftsman dealing with document management. I hope to educate these PLM gurus in the true application of 3D CAD. I will again present this to the readers.

If you would like more information or to download ZW3D or IronCAD With 53 years of experience in engineering, 17 years in manual board design as a contract engineer, 35 years in 3D CAD sales, support, training and providing engineering services, I have a high level of understanding of today's 3D CAD engineering world. For many it is in chaos. If you are having problems or just interested in this subject please feel free to call and we can discuss them. There are so many simpler solutions available that will save you time and money.  Please visit our Viewpoints for more articles on our industry that may interest you. Please visit our Viewpoints for more articles on our industry that may interest you. See you online. Joe Brouwer 206-842-0360 |

TECH-NET ASSOCIATES | RENDERING OF THE MONTH | CAD•CAM SERVICES

HARDWARE | TECH TIPS | EMPLOYMENT | CONTACT