|

Celebrating 30 years 1987-2017 Engineering Ignorance Defined CONFUSED? MBE - Model Based Enterprise MBD - Model Based Definition  | ||||

|

These articles are a must read when relating

to this subject:

Why MBE/MBD/PMI Will FAIL Why MBE/MBD/PMI Will Fail Part II Here are other articles defining the state of the industry! Engineering Ignorance Defined II Top 5 Reasons to Use MBD DEBUNKED!

Engineering Ignorance Defined III

Engineering Ignorance Defined IV

Engineering Ignorance Defined V This is the second article where I reference Oboe Wu. Now I would not directly criticize anyone but he is the the manager of Solidworks efforts on MBE. Check out Oboe's profile on Linkedin. There is no experience on engineering documentation. He has never made a drawing, created a 3D model and generated an AID (Associated Information Document (drawing)), or a PMI. Never reviewed, approved and released any engineering documentation to document control and to manufacturing. Obie has a MSME and an MBA. Obviously he is very bright, but he groomed himself for management not drafting or even design engineering. Who in the world would put him in charge of engineering documentation? So, who would you look to? A draftsman, of course! Drafting, not engineering, was in charge of engineering documentation. Engineering documentation is in chaos. It is now being defined by those that have absolutely no applicable knowledge. Engineering Documentation Today!

Here is the first time I encounter Oboe. Watch the video. He has no clue that we have been delivering the 3D model first with the paper print and now as a PDF of a completely defined AID (Associated Information Document (drawing)) for over 27 years. He is obviously is under the impression we only send the AID (drawing) to manufacturing. He has no direct knowledge, so who told him this? Does this ignorance run rampant through out the 3D CAD industry? You would think that Solidworks management would know how their users use their product? Sadly, all of the major CAD companies are now nothing more than large corporation focused only profit. Solidworks Totally Misunderstands MBD Mr. Wu said one of the most uninformed statements I have ever heard from anyone in my 33 years in 3D CAD. Remember that he is "Global Product Manager - Dassault Systèmes SolidWorks Corp." It happens about :47 seconds into the video. “We have to project the data down to the 2D drawing and then ask somebody else on the shop floor to, the supply chain, to reconstruct the 2D drawings into 3D". But Oboe and Solidworks are not the only ones that are ignorant of the engineering deliverable process, PTC has no clue also. Look at this promo piece for MBE. They also make the same mistake that the 3D model is not delivered with the AID (drawing). How can a 3D CAD company the size and experience of PTC have this oversight. They have been delivering the print and 3D models since the late 1980's. It is truly shocking. PTC Creo Totally Misunderstands MBD Here is an article showing how much more effective the AID (drawing) is as compared to the PMI. Now why would you listen to me over the PTC and Oboe? I am a contract draftsman with 53 years of experience with many different companies. My First 17 Years or "How did we do it without 3D CAD!" What does that mean? I have manually drawn thousands of drawings and am still creating many AIDs. I have tens of thousands of hours designing in 3D CAD. Who would you listen to? Take a look at some of my projects. Let's see some of Oboe's work. PMI vs AID (Associated Information Document) The Death of the Drawing TECH-NET Engineering Services! But this is nothing new in the industry today. Engineering.com who published this article is deep in the pockets of the major CAD companies. You have never seen an article negative to any of them. Any comments pointing out weaknesses in the programs or processes I post are not allowed. Why? Their bread is buttered by major CAD companies. By only agreeing with all of this insanity they are doing an incredible disservice to the industry. Update: 2-1-19 Here is a comparison article between Solidworks and Onshape sponsored by Onshape. There are actually two referenced in the article. Both very favorable toward Onshape. You wonder how much Onshape paid? Be sure to read the comments they are very candid. Engineering.com has never approved any of my comments because they were contrary to their vested interests. Let's take a look at Oboe's article. Call out Multiple Features Together with a Single Annotation

First Example This is most insulting article to the engineering profession I have ever seen. He shows us how we can detail our parts in PMI. This is basic drafting. Even the most inexperienced 3D CAD engineer knows this. If they don't they should be fired. No company could afford this level of ignorance in engineering. Oboe has no clue that this is incredibly basic common drafting knowledge. Sadly he is in charge of Solidworks engineering documentation development, globally. I really doubt if he even wrote this article. Solidworks users have been delivering the model and AID for over 23 years! This is unbelievable! How many of you that actually do engineering don't know you just reference one of the multiple duplicate features by denoting so many places? 5 X .250 hole! If you don't, find another career. This is such basic drafting knowledge it is unbelievable that there would be a need for this article. If there is we are truly lost. It reminds me of DFM (Design for Manufacturing). For the life of me, I cannot understand the need for this acronym. How do they expect us to design, not for manufacturing? It is totally insane that some take this seriously. I can tell you if someone came up with this subject 50 years ago all of the design engineers and draftsman would just look at them and scratch their heads. Any experienced Solidworks designer has to be laughing at this article. I may not care much for Solidworks, but virtually all of the experienced users are engineering professionals. This article is an embarrassment. This ignorance has to be blatant though out Solidworks corporate to allow Oboe to publish it or even to be in this position. Didn't the fellows from Engineering.com realize the simplistic content and warn him. But then the Engineering.com just goes along to get along and collect the ad revenue. Oboe needs to sit down with me for a couple of days. I could educate him on the needs of engineering as it relates to documentation. I could even define a document control product a company the size of Solidworks could develop that could become a standard and serve the complete industry. The Ultimate Document Control System As I look out into the industry, I seem to be the only one presenting a contrary view and process. How can this be possible? Surely, I can't be the only one seeing the massive waste of time and money in PLM and MBD? I can tell you engineering and manufacturing was much more cost effective when it was based on the manual drawing. All we did was add the 3D model and it is used only for a pattern. Sadly, someone used the word digital and the Infotech folks showed up to show us the way. Yes, the way to Chaos!! Second Example As for the second example, how does one get to such a situation. Is this automatic dimensioning? I can tell you that has never been successful, as well demonstrated by this article. You end up spending more time cleaning it up then manually putting it in correctly. When you detail (add dimensions) you are reviewing the design for errors or even a better design before releasing it. Errors are devastating if they make it to the assembly process costing 10 fold in wasted material and slipped schedules. The minimized 3D detailing in PMI is the worst engineering deliverable ever devised. Not so much for manufacturing but for the engineering process. Years ago in CADKEY we could do what you could only call 3D detailing. We only used it for simple illustrating. It is virtually impossible to check. Sadly, checking, which was the most important step in engineering in the past has all but been eliminated.  Again I will reference this article, the differences are stark! PMI vs AID (Associated Information Document) Now I have to tell you this PMI concept is completely worthless. Most of those that are promoting MBD and PMI are like Oboe and have no drafting experience and no clue. I have found PTC in the same boat. There are a few self proclaimed GD&T gurus promoting what is a complete bastardization of GD&T. Management, basically ignorant of the process, takes them seriously. There is no short cut for engineering documentation. Again, any mistakes here costs 10 fold down line with incorrect parts and slipped schedules. Here is a comment from a MSME PE on MBD and PMI being applied. "The big problem is, any failure will be blamed on the responsible engineers and not an unworkable system. MBE is already being backstopped by drawings in many organizations that are forced to use MBE, but the drawings are frequently not in the release control process because they are not the "primary" data driving fabrication. A fine mess.." Trust me the smart folks are doing AIDs (drawings)!! Sadly, engineering is not in charge, it seems to be the Infotechs, the PLM gurues, CAD companies and maybe the bean counters, an obvious formula for disaster. It is time to put engineering back in charge of engineering. No one higher than a BSME. We need those that have applicable experience doing engineering design. If a fellow cannot present a resume, rich with design experience and management, he should not be in charge of any engineering processes, from design, documentation and document control. No MSMEs or PHDs allowed!Again I reference: Why MBE/MBD/PMI Will FAIL Why MBE/MBD/PMI Will Fail Part II So what is the state of engineering documentation? Engineering Documentation Today! So What "HAS" Gone Wrong with Engineering? So what "HAS" gone wrong with Engineering? Part II So, what "HAS" gone wrong with Engineering? Part III We haven't made a Drawing Since 3D CAD was Introduced! I will use Boeing for the bad example of how this convoluted system came to be. Boeing got rid of the drafting group and the document control years ago. They put engineering in the hands of Dassault and their convoluted Catia 5 PLM. They transitioned at a time when Boeing was delivering the 3D model and a paper prints generated from the 3D model to the suppliers. Do you ever wonder why they keep bringing up paper all the time when we have been releasing our AIDs (drawings) as PDFs for the last 17 years? It is shocking that Boeing would get rid of Drafting as a standard process. Some ones still has to do the drafting. Engineers never made drawings, but as they became 3D CAD engineers and now responsible for the documentation, drafting as a standard function should have still been in place. Today, with PMI, those that don't have any engineering design and documentation experience are trying to recreate the wheel, and, of course, have failed. Educating the New 3D CAD Engineer Engineering Yesterday & Today Engineer's Job Description The Search for the Purple Squirrel Even though we have been delivering our AIDs (drawings) as PDFs they are still calling them paper drawings. It is better than them calling them "2D" paper drawings. I really hate the moniker "2D Drawings". I mean, what other kind of drawings are there? It is so stupidly redundant. I was supporting Boeing and virtually every Boeing supplier with PC Based 3D CADKEY. I was getting calls telling me that Boeing was not delivering prints. Boeing did this without any warning or a transition process. The suppliers were on there own. There was no way to view the PMI. The only solution was to purchase a seat of Catia 5 or Enovia, the viewer. I think the cost of Enovia was $5,000.00. The suppliers were up in arms. But Boeing just said if you can't do it, we will take you off the list. Of course, all of the suppliers were in the same boat so the cost of the parts started going up. It cost Boeing more to produce the documentation and cost the supplier more to duplicate the documentation resulting in increased manufacturing costs. CADKEY soon provided the ability to read Catia 4 and 5 native files, but not the PMI. Most suppliers were just working around Boeings requirements. Soon, Boeing realized that the parts were not being read correctly, Catia 5 delivered some of the most corrupt parts and now needed to have a validation report for all parts. This required a 3rd party validation software package, price $5000.00. The cost kept going up. Compare and Validation Programs? Band-Aids for Self Inflicted Wounds! Can the 3D Model Be Used as the Design Authority? Quoting Tools: CAD Dimensioning Another Band-Aid for MBE! Adobe even released Acrobat 3D that would read the PMI and deliver the part as a STEP just with an Adobe Reader. But Boeing was set on the suppliers being able to read the Catia 5 native file. Adobe discontinued the product. There are 5 major 3D CAD programs, each is putting out its own native PMI. There is an idiotic attempt to create a STEP format. But you still have to create the STEP file (this should be a DUH, moment). Could we use the STEP as the engineering deliverable? Trust me, that concept is far beyond the folks that are researching this. Do you think there is a draftsman in the bunch? You must be kidding, most don't even have an engineering degree and have never worked in the industry.

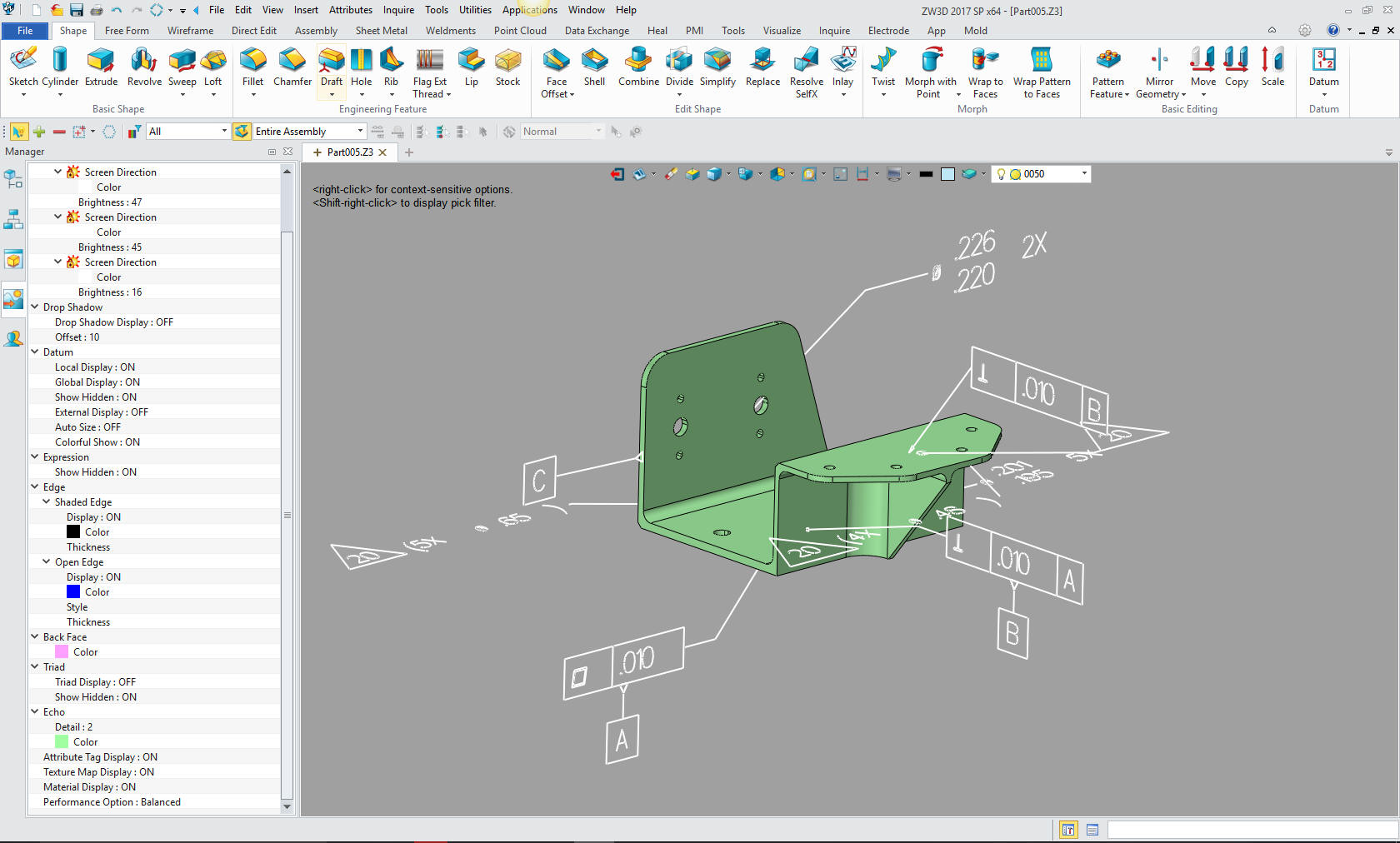

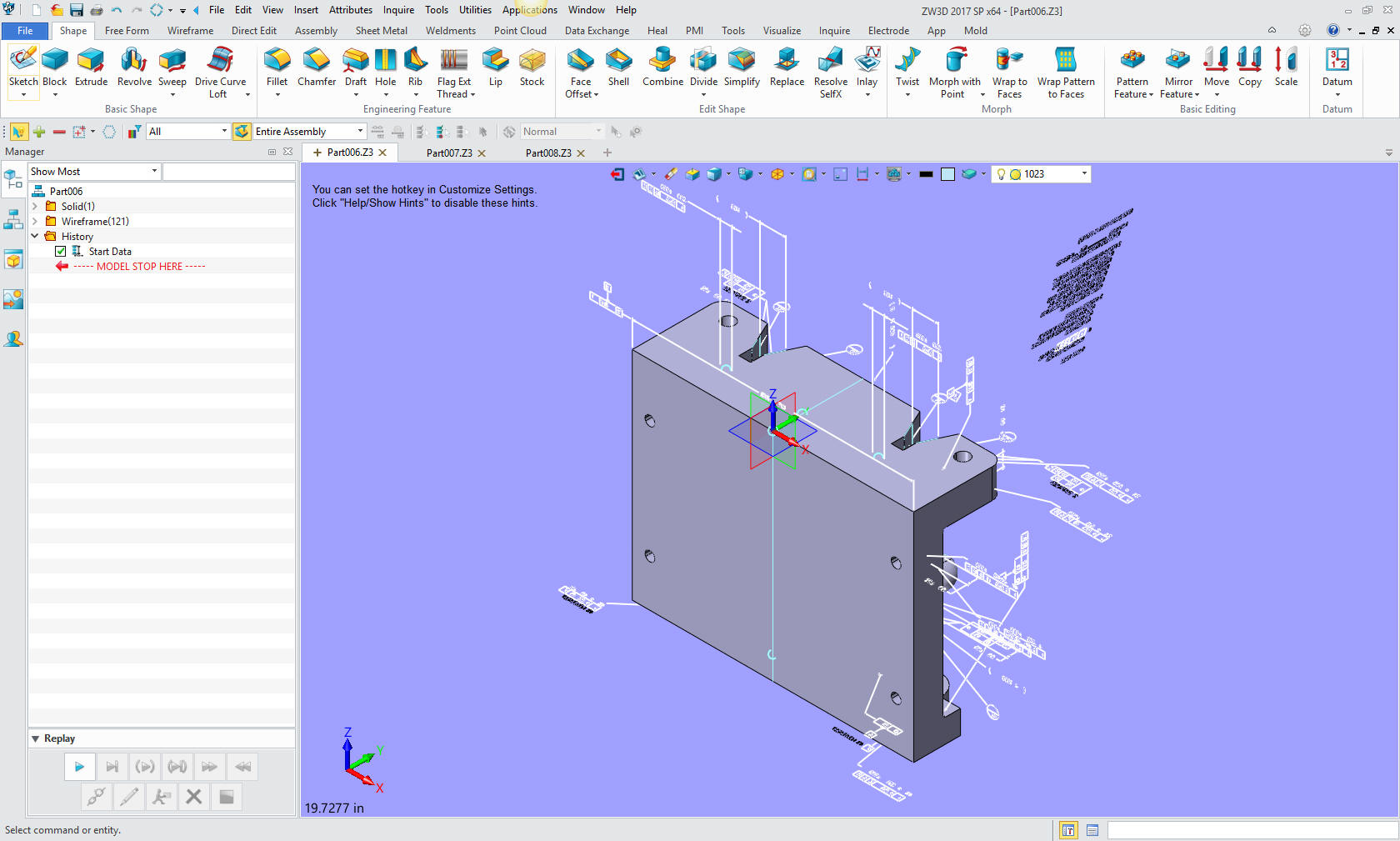

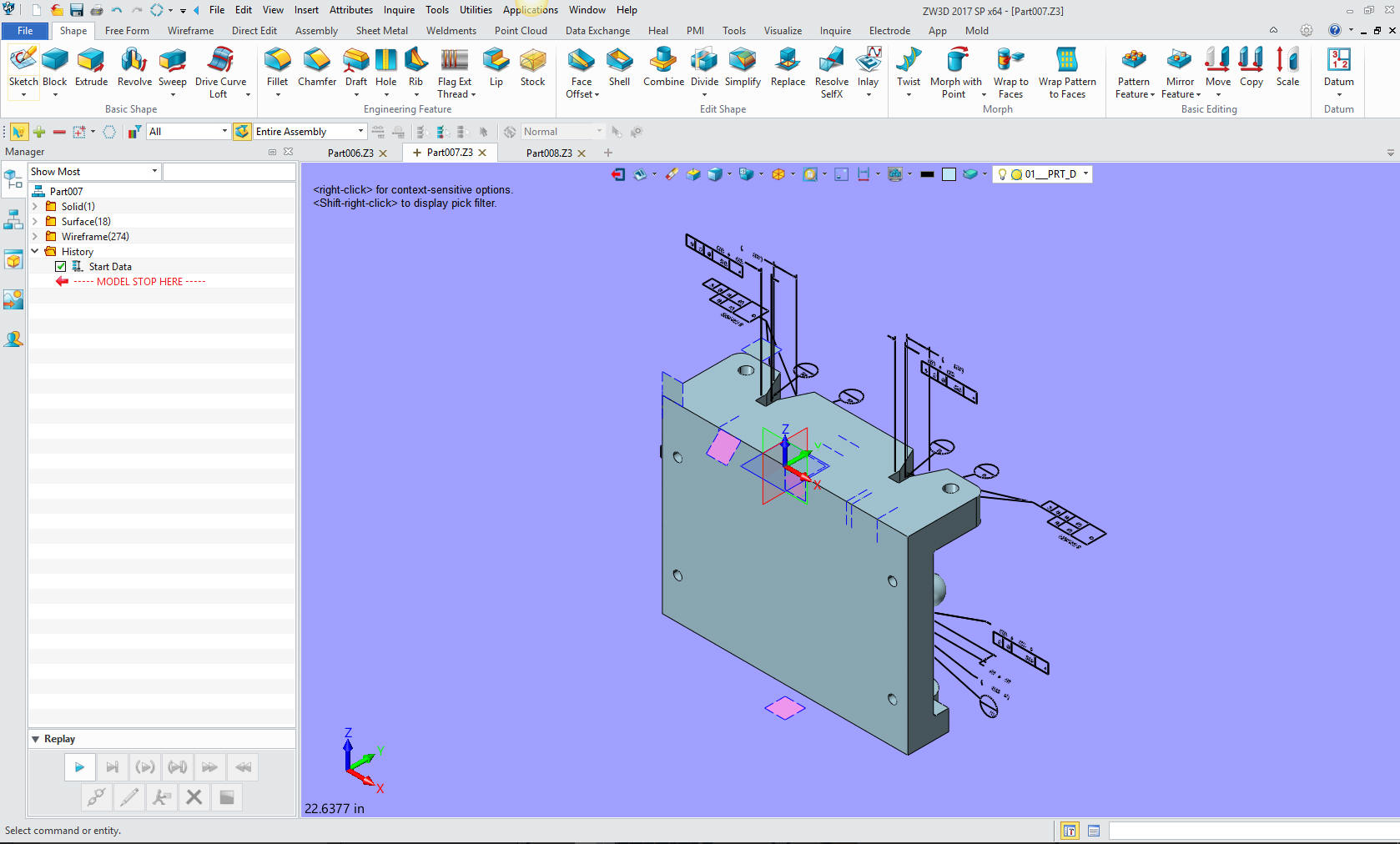

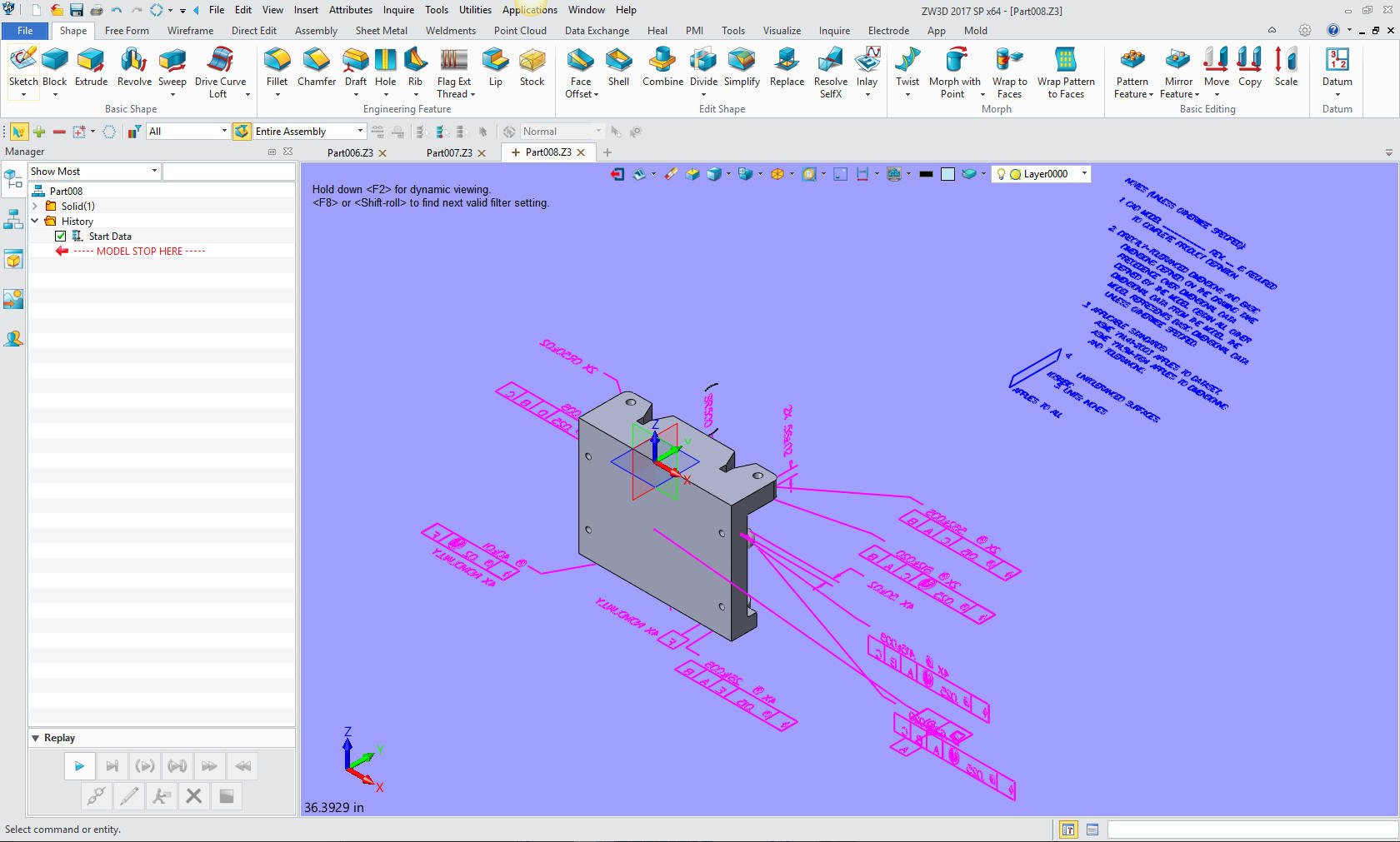

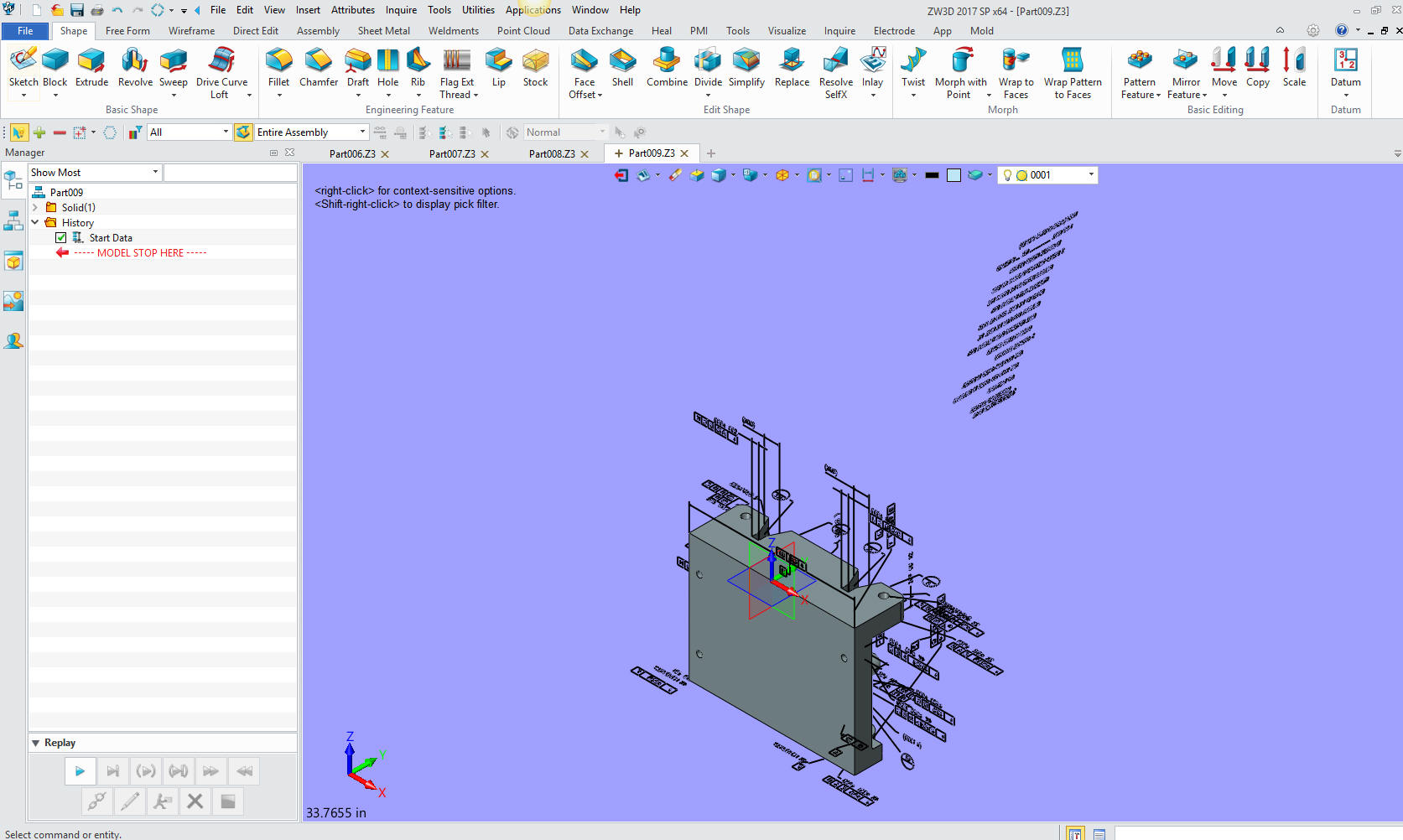

Take a look at this convoluted waste of time. I have downloaded these and will have another PMI vs AID Part II. Go ahead download some of the native PMI files or the STEP files and read them, if you can. All we did was add the 3D model. In the past the drawing was the only document needed, what is so hard to understand? I am now convinced, engineering was more cost effective when the engineering authority was based on the manual drawing. MBE PMI Validation and Conformance Testing Project Funny as it may be, I represent a 3D CAD program that can directly read the PMI from Catia 5, NX, Creo and Solidworks and utilize the 3D model. And it seems to work well enough to view the PMI documentation and 3D model. I don't think even the high end programs can read each others PMI, otherwise why all this research into STEP and other translators? Free PMI Importer? Here are some images of PMI imported with ZW3D. Catia 5 PMI Creo PMI

Solidworks PMI NX PMI

Looks like Catia and NX provide the best translation. Interestingly enough I replaced two Solidworks seats with ZW3D. I had to investigate how they could view the AIDs (drawings). I found the edrawings 2017 program adequate. Funny thing they could not effectively read the PMI of their own product, it was quite corrupt. I got curious and decided to look at Creo. They have a good viewer also. It also did not read the PMI. I will be doing an article about replacing of the major programs with ZW3D, especially Autodesk and PTC with their Subscription only model. I know, most of you know I could go on and on and on, but for those of you that have not been so lucky, here are some more articles on the industry from the quintessential draftsman. Viewpoints on the Industry If anyone out there has any power to influence this chaotic mess please feel free to call. It truly is not that much of a problem. We used to do it more cost effectively with just the manual drawings. 3D CAD and the 757

TECH-NET Engineering Services!

|

TECH-NET ASSOCIATES | RENDERING OF THE MONTH | CAD•CAM SERVICES

HARDWARE | TECH TIPS | EMPLOYMENT | CONTACT