|

Engineering Documentation Today! | ||

|

A Completed Engineering Drawing is the 3D Model!

"Engineering's only purpose is to make available complete, concise and unambiguous

documentation to manufacturing." I read this post on Linkedin:

Engineering Documentation - Cost of doing Business?

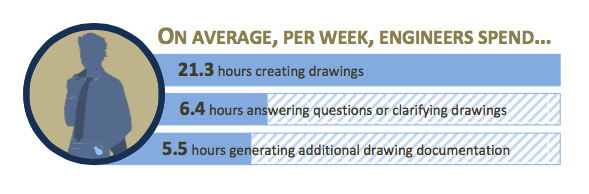

These are the statistics the author was using to base this article.

(There are no engineers that wear ties!)

The statistics were from this article. Here are a few comments I made in reference to the engineers time. First Point: In reference to engineering

documentation (drawings). The documentation goes out complete and

should have no ambiguities. If manufacturing has to call, the

designer, checker and lead engineer would be sternly reprimanded.

The Author responds that he thought firing engineers would be bit extreme

and we should educate them. I have been a design draftsman for 53 years, of which the first 17 were manual drafting. My complete career was as a contract engineer, I only working direct for Boeing, Seattle. I was a Boeing trained draftsman, we were trained with the best standards in the industry. My First 17 Years or "How did we do it without 3D CAD!" The first thing a company should do is have an engineering documentation standard. What is required to release the documentation? I would suggest the Drawing Requirements Manual by Global Engineering Documents. Even though we do not create drawings anymore (described later) it has all you need to get a good engineering department started. Also throw out the CAD system vendors and InfoTech folks if they are in the way, they should only be tools for engineering management. Or you could, of course, call me. This is not rocket science, it is just not in a degreed engineers training or mind set. Joe Brouwer Let's tackle the first statistic 21.3 hours creating drawings How we did drawings or documentation pre 3D CAD.

We would then plan the drawing. Reviewing the part and how many views would be necessary to completely define the part.

The drawing sizes defined the average time it would take to do the job. I think D size took 24 hours. I am sure the electronic drawing packages like Autocad cut it down since you didn't have to erase you just deleted. Now, when the draftsman completed the drawing it went to the checker that made a yellow or red mark on every dimension and note on the drawing. It would be returned to the draftsman to do what were called the "Pickups". This was a mentoring process. Soon the draftsman was very familiar with the product and quickly moved to Design Draftsman and maybe to checker. The drawing was checked and then reviewed by specialty engineers: Manufacturing, materials, stress, etc and they signed off on the drawing. Then the lead engineer and supervisor signed it off. This was at Boeing. Smaller companies the lead engineer was the final signature. This is the process! There are no short cuts. Engineering is the last place you want to automate or minimize. The errors here are devastating to the project down the road at manufacturing or assembly. The lack of an established checking procedure opens the door to Murphy and the chaos he causes. The cost of wrong parts, the investigation, the solution, the reordering, the paperwork and the worst "Slipped Schedules". This is probably where documentation is failing today. We have the engineer now the designer and draftsman without any formal drafting experience. Today, they do not have this hierarchy. The engineers now works pretty much independent and on their own. The Death of the Draftsman or “Where has all the talent gone?”

Engineering Yesterday & Today So how do we create our documentation today? Today the new 3D CAD engineer is the one that creates the documentation. To toss a model to a draftsman seems to have gone away. Boeing has eliminated the complete drafting group and are letting the draftsmen go by attrition after renaming them to Engineer Technicians. Engineers are now responsible for design, documentation and even data management. FIRST - IN 3D MCAD WE DO NOT CREATE DRAWINGS. What do you mean Joe, of course, we create drawings.

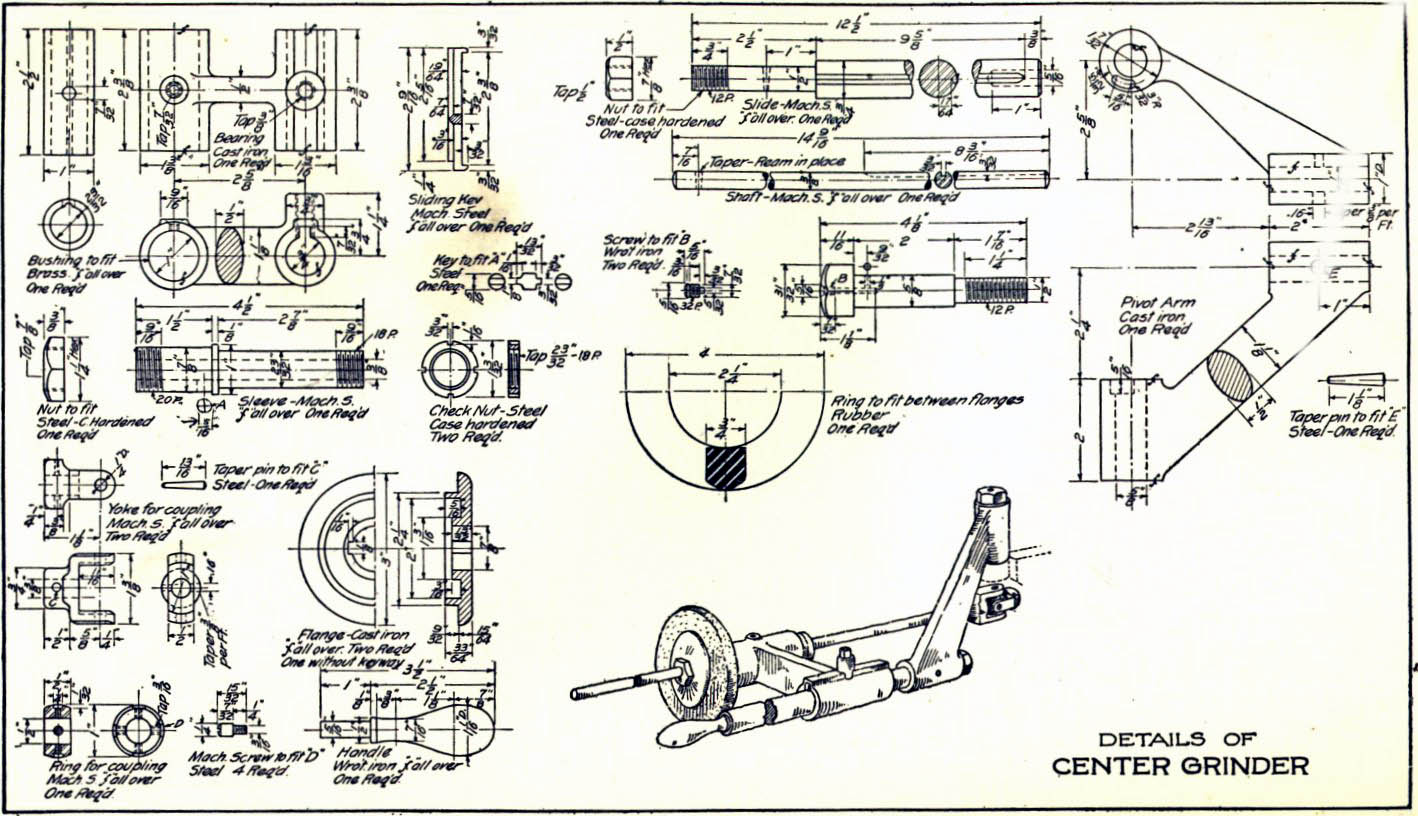

Look at this image again.

For the life of me I can not imagine anyone taking more than a couple of hours to correctly detail and annotate this part. Today, detailing is the simplest job in engineering. Even a draftsman could do it. All you do is put on the dims. Yes you have to know your datums and tolerancing but that was the same pre-3D CAD. This is what was called detailing and even the new draftsman were trained to do this. We would lay out the views and detail them. So if you are having a problem here you need to take drafting classes. Most engineer only get one drafting class in college. I had 480 hours in my Boeing supported drafting training program. There is one more very import fact. These are AID (Associated Information Documents) they are basically reference documents that travel with the 3D model. Today there is an idea the the 3D model should be the authority. But the 3D model is really nothing but a pattern. The AID along with the model should be the authorizing document with all of the pertinent information. But the documentation does not need the level of detail of the drawings of the past. I believe we should fully detail the part, not for manufacturing, but for engineering providing a second look by the designer. I have 53 years of designing and I find an error every time I detail the part. What chance does a newbie engineer have? So you see that an engineer per the statistics is doing 21.3 hours a week doing documentation, this is a hugely intolerant problem. Education is the key, but long before they walk onto the job. Educating the New 3D CAD Engineer - 2015

The Second Statistic: 6.4 Hours Answering Questions or Clarifying the Drawings

This is where heads would roll. In the past when we

released the drawings we were relatively certain that the parts were correct

and could be manufactured. Yes, yes, there were times when an incorrect

drawing would get by. But

most of us were professionals and there seemed to be more eyes on the design

and drawing in those days.

There seems to be a new engineering discipline "The Dimensional Engineer". If the company has one of these, I am not sure where they enter the process. In the past the draftsman was trained on tolerancing, reinforced by the checker. From what I have seen these are a bunch of GD&T gurus. GD&T is a bit of an overkill on tolerancing as compared to simple linear tolerancing. In fact, we should be teaching linear toleracing before we even embark on learning GD&T. All of the datums are implied, a great learning exercise.

I think that management wants to cut this step with the bet the parts will be right. But according to these stats they have bet wrong. Cutting cost in engineering just makes the cost much higher with incorrect parts and slipped schedules. The Third Statistic: 5.5 Hours Generating Additional Drawing Documentation. If a good checking process was in place this step would not exist or would be minimized. The Last Statistic: 6.8 Hour of Design This by far is the most disturbing stat. Design does not consist of 3D CAD only, there is research time, coordinating time, analysis time, component selection, etc. Yes, the first question in starting any design is how did they do it before. You do not want to recreate the wheel. Also, there are experienced engineers around you to ask any questions. So can you image trying to schedule a job when the basic design process is less than 17% of a weeks work. I would tell you that the complete staff would be fired. A company does not have the money or time to bring these stats into reality. What should they be, I will be generous and say 12 hours design to two hours of documentation. That should include checking and picking up the errors prior to engineering release. If it comes back from manufacturing with problems. Many should be reprimanded and soon fired if the situation continues. No company can afford this level of confusion. Now we will go to the Manufacturing stats

8.3 Hours Creating Manufacturing or Quality Documentation First there are no machinist. We now use the 3D model as a pattern for CNC programming. There is very little documentation with CNC. When the program is done it is sent to the machine operator that does the setup of the material in the CNC machine. There may be a few knob turners around but they went the way of the buggy whip decades ago. Now we may need tooling. But that is no different than before. It is much more efficient since they have the 3D model to use as a basis for designing the the tools. Fabrication is much different than machined parts. There is very little CNC done. If it is done at all it is in sheet metal part manufacturing. So this is a very narrow study done by those that are really not involved in day to day work in engineering or manufacturing. So 3D CAD has cut the manufacturing time immensely. This was much longer pre 3D CAD. That is one thing wrong with this study it doesn't compare it to anything.

Manufacturing will take any documentation, heck, even if it is drawn on a napkin. They do not have a dog in the design fight. These PLM/MBD folks think manufacturing cares about the design. They take the information in any form as long as they can cover their butts. Their complete goal is deliver the part as defined so they can send the bill. THEY ONLY CARE ABOUT GETTING PAID! Remember they have to do the quality work or the customer does not come back. All questions are charged to the Client.

If we are going to have engineers do form, fit and function design, they have to know this before they show up on the job. This was basic drafting knowledge. Again I will post this article, please read what my associate Matthew Sawtell wrote:

Boeing the leader in the flawed MBE demands that the supplier has a program that validates the native Catia model. "The native Catia model is the authority". Then they send a scanned drawing in the form of a PDF for the supplier to do the 3D model. You have to chuckle at the huge violation the the model as the authority. What do they use to inspect. The drawing of course. LOL

Compare and Validation Programs? You would think a company that would have these strict rules would have a group of young engineers converting drawings to 3D models for CAD practice and product knowledge. This would assure compliance with the basic rule. All You Wanted to Know About Drawing to 3D Conversions

Can the 3D Model Be Used as the Design Authority? Conclusion If this is the condition of engineering documentation today, we need a paradigm shift. But sadly, it does not start with the 3D CAD engineer (he/she seems to be quite ignorant according to the stats) it starts with engineering management. Boeing got rid of the complete drafting group, thinking that the engineer would now do the design, documentation, release of the documentation, maintenance of the documentation without any transition process in place. PLM managers and the infoTechs are now in charge of engineering where the data management is more important than the design. And to add insult to injury, Quality Control joins them with their failed MBD (Model Based Definition) where all documentation is minimized to only provide the minimum inspection information (PMI). Sadly, they use a bastardized minimized version of GD&T, that does a disservice to the technology.

This is why we are having these deplorable statistics. The engineer was never trained to do this kind of work. Most is grunt work not worthy of their education, but it is now the nature of the beast. We have to now have a new engineer Educating the New 3D CAD Engineer - 2015

We need to put engineering back in charge of engineering. But it is sad to say, there is no one with enough applicable knowledge to make this happen.

Joe Brouwer

|

We would then place the orthographic views, many

times we would trace the layout. Sometimes if the layout had corrections

(underlined dims) we would draw it from scratch. Remember the drawings were

mostly drawn to scale, but the dimensions were the qualifying factor.

There was a common understanding and sometimes noted on the drawing "Do Not

Scale the Drawing". A scale was a ruler! More than likely many young

engineers have never seen one.

We would then place the orthographic views, many

times we would trace the layout. Sometimes if the layout had corrections

(underlined dims) we would draw it from scratch. Remember the drawings were

mostly drawn to scale, but the dimensions were the qualifying factor.

There was a common understanding and sometimes noted on the drawing "Do Not

Scale the Drawing". A scale was a ruler! More than likely many young

engineers have never seen one.