|

The Part – The Basic Component

of any Design

The Secret of Part Numbers

After I wrote my article on The Assembly Defined, I realized we also needed an article on part design. With the introduction of 3D design, much of the industry seems to have moved away from the basics of engineering part development and documentation. I have to give a complement out to the smaller

companies before they jump on me. They have really not changed the

process from the past. They still supply completely detailed documents

as a PDF along with the 3D model. This is very cost effective requiring

no special software or processes and lends to a much simpler document

control system. Part Design I was a board draftsman for 17 years. We did all of

the part design on a drafting board. We would create the layouts where we

developed the design in which we would "layout" the complete assembly. Of

course, designing one part at a time. We would give those layouts to

draftsman to create the detail drawings or detail them ourselves.

Part design was in the realm of the draftsman. Yes,

there were a few board engineers but very few. A couple of industries

had a group of board engineers, I remember one was Pratt and Whitney in

their Gas Turbine group. Here is a story working as a contract engineer at

Pratt. In the 1970’s. "Even though we were

taking layouts from the engineers and detailing the parts. I never

stopped being a designer. I was assigned a heat shield for the

afterburner ring. The shield was in two pieces designed radially. I

said, wow, his is going to be a horror show to create the tool. I

recommended they design it on the side. My drafting lead and supervisor

let me do a layout and they presented it to engineering. The engineering

supervisor came down and took the drawings to redesign. Like I have said

"Job Shoppers" were mostly made up of highly experienced design

draftsman. We were the very best, if you didn't know your stuff you were

out the door in a week. There were virtually no engineers on the board. Why

did Draftsmen do most of the design? Drafting was a mentoring system. You would take

your training and walk on to the job. You would be assigned a drawing.

When you were done you would give it to the checker, a senior draftsman. The checker would

put a red or yellow mark on every dimension and annotation on that

drawing. It would be given back to the draftsman to do the “pickups”.

After a few years the draftsman would be completely familiar with the

designed product. Personally, I was a born draftsman and excelled. I

was 22 and D draftsman at Boeing, they put me on layout and development of

parts, assemblies, studies and trouble shooting. The young engineers

were taking my layouts and creating drawings under my supervision. I

went to the supervisor and asked for more money. They moved my salary

from $2.90 to $3.00, I just chuckled. There were job shoppers all over. Contract

engineers making twice the money as the directs. I quit and headed to

the San Francisco Bay and got my first contract for the whopping $4.50

per hour. I never went direct again!! My last contract was with Ford

Aerospace at $35 per hour in 1988. Then I founded TECH-NET.

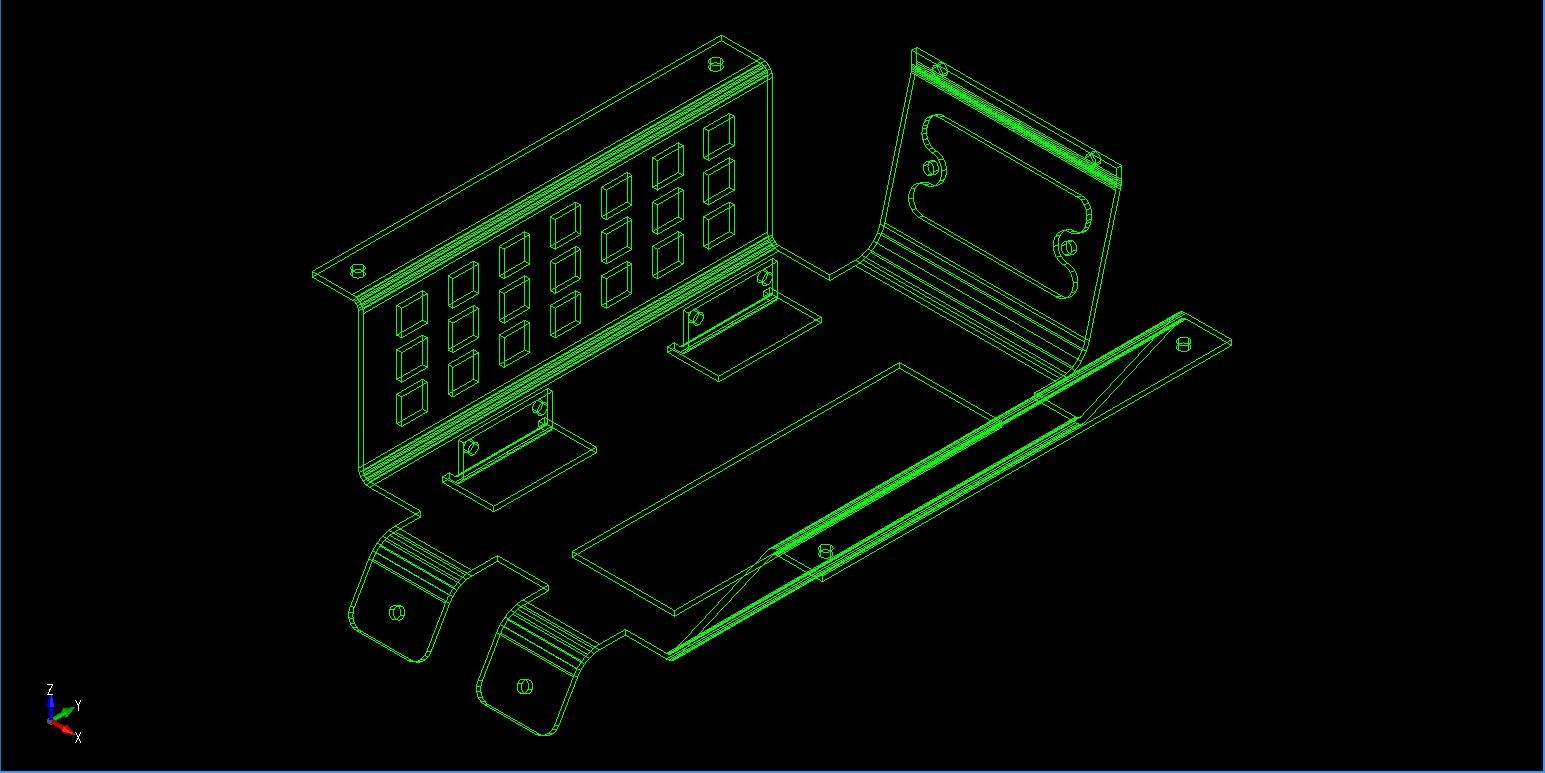

One more point There is a term that has grown in popularity. DFM (Design for Manufacturability). If you walked into a drafting room 40 years ago and asked the engineers and draftsman if they were designing for manufacturability? They would just give you a blank look and say "What else would you design for?" Okay, okay back to the original subject. Enter 3D CAD I was introduced to Computervision CADDS 4 3D

CAD system in 1982 at Williams Research in Walled Lake, MI. I was on my second stint at Williams and they had

Computervision. They allowed me to train in the evenings. I soon was

designing in 3D wireframe, with green entities on a black background.

Now I will not get into the difficulties here, but trust me it wasn’t

easy.

But getting back to part design, draftsman were the

only ones using 3D CAD. The drawing was still the final product. Even though

the print was plotted on large plotter they were still called drawings. I

personally have never created a professional scratch drawing on CAD. The

larger companies and I completely missed the Autocad bullet of the

electronic drawing and went directly to 3D CAD. The drawing was dead.

From that moment on we just detailed created views from the 3D model in

documentation modules.

Engineers were not on 3D

CAD in the beginning. But the writing on the wall began to appear in

1985 at Solar Turbines in San Diego. They let go their complete 3D CAD

direct

drafting staff and moved the

engineers to Computervision CADDS 4X. I stayed on to train them. Many protested

but were told get on the CAD system or get fired. Actually, they became

very good CAD designers and, of course, were now responsible for all of

the documentation. I am sure that cost the company a pretty penny.

But that was not the case for most companies the

draftsman was still the CAD designer. I took another contract with

Williams and then got a job in Akron at Goodyear. I was there for a week

and a Boeing job came through in Everett, WA. My family was already in

the Seattle area and I was looking forward to getting back home. I was put on the board after 4 years of 3D CAD. I was whining about not being on CAD and someone said there is a 3D CAD system on a couple of Compaqs in a small office. It was PC based 3D CADKEY. Being experienced on 3D CAD I learned the system in 2 weeks of lunch hours. It was also a wireframe modeler and very similar in operation to Computervision. I proved to the management that this system could equal the Catia 3 seats that were in the group. I have documented this in other articles but by the time I left there were 25 seats of CADKEY and soon 45 in the Flight Deck group alone. They had 1500 CADKEY seats in Boeing Commercial. I know, I know, more fricking history, but it all

has to do with part design, be patient. I again saw the writing on the wall, CADKEY cost

less than $10,000 with a 386 computer and a 19” monitor. Computevision

was $250,000 per seat and I am sure Catia 3 was over $100,000 and tied

to mainframe computers. CADKEY

could actually outperform both of those systems. All they had over

CADKEY was rudimentary surfacing that soon showed up on CADKEY in the

form of an add-on called Fastsurf in the late 1980’s. I founded TECH-NET in 1987 and started selling, supporting and training CADKEY and provide engineering services.

Virtually all of my students were draftsman with a couple of chief cook and bottle washer engineers from smaller companies. They took to CADKEY like a duck to water. I was selling CADKEY to Boeing and all of its suppliers. CADKEY was the only PC based 3D CAD program that could talk to Catia 2, 3 and 4 and was the only viable solution until the release of Catia 5. But even then CADKEY included the ability to import and export native Catia 4 and 5 native files. Actually the transition from Catia 4 to 5 was a fiasco. Catia 5 could not directly read or even utilize Catia 4 parts. CADKEY was used to convert native parts from Catia 5 and other native formats to Catia 4. The parts had to be manipulated because Catia 4 could only read a 34 meg file. Boeing would be miles ahead today if they would have standardized on CADKEY. Many suppliers are still using CADKEY, IronCAD and ZW3D to work with Boeing Catia 4 and 5 files.

I have worked with Boeing and Catia for over 30

years. Dassault is responsible for keeping Boeing one of the most

ignorant and isolated manufacturing companies. Their lack of

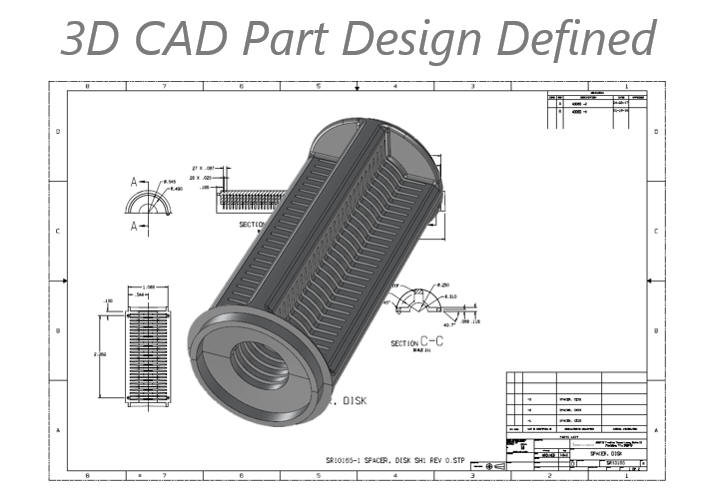

interoperability is beyond belief. Part Documentation

Manufacturing only gets parts. Rarely do they

get the assembly. So they need incredibly clear definition of the parts. Designing the part is just one component of a

complete process. We design the parts and make sure of their form, fit

and function in the assembly. But we now have to completely define the

part to assure duplication at manufacturing. With the drawing it was all together the part was

the drawing. Today we design in 3D and the documentation is done at the

end of the process. It is very, very

simple to detail a part and add other annotation and notes in the

documentation module. The

documentation is as important as the part design itself!!

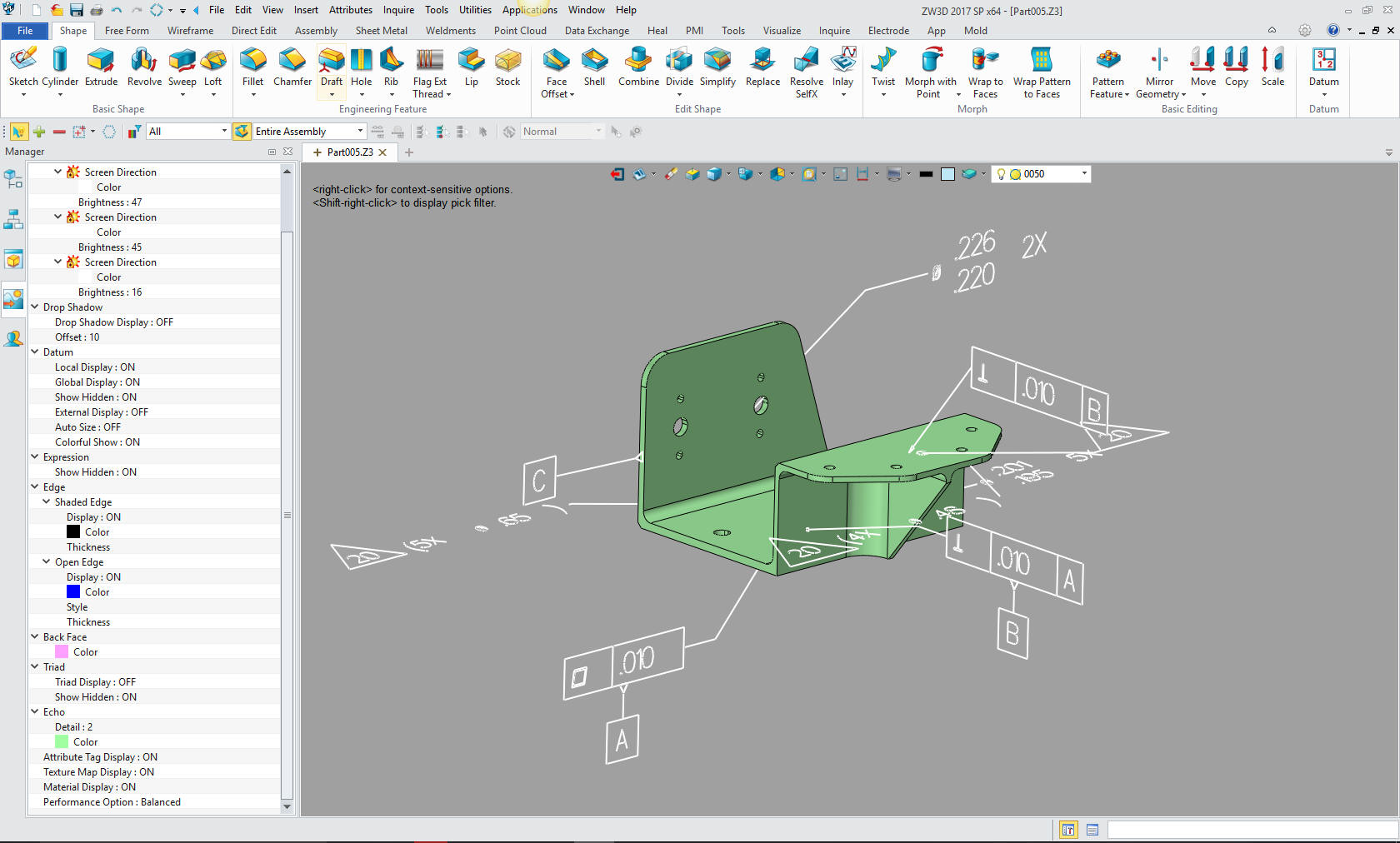

Making the Model the Design Authority Today the PLM and MBE folks have tried to minimize

our documentation. It has totally failed.

As a draftsman, I really have a problem with the PLM folks. They

just do not have an understanding of what we do as designers. I really

don’t think they have even looked at the past drawing based process.

The PMI (Product Manufacturing Information) format is bringing productivity to a standstill. We send out the part information in a native system sensitive format. This makes the native part file the authority. Sadly, Catia 5 produces the more corrupt part files. Instead of making the companies produce a standard usable file the industry allows the major CAD companies to dictate the format. Yes, this is a recipe for disaster. Solidworks: MBD Model Based Definition PMI vs AID (Associated Information Document) Part design today with the large manufacturing

companies that are utilizing PLM and MBE are in chaos. Smaller

companies, luckily cannot afford the PLM and MBE overhead. Yes, their

data management requirements are much simpler and more standardized. Sadly, PLM has overly

complicated a very simple “Document Control” system, of the past.

Standard Cloud Based Engineering Document Control Standard Cloud Based Engineering Document Control Part II This is a hard subject to bring to a conclusion since it is the basis of all engineering. Everything we do begins with part design. You see the ads from the major CAD companies touting these incredible designs from airplanes to cars. If you are impressed, you really have no clue. They are all composed of mostly simple parts designed one by one by, hopefully, by those that are familiar with form, fit and function design with common industry standards and the standards of the company they are working. We used to say that an airplane was nothing but thousands of parts flying in close proximity. Product knowledge, proven standards and

So there you go Part Design in a nutshell

TECH-NET Engineering Services!

If you are interested in adding professional hybrid modeling capabilities or looking for a new solution to increase your productivity, take some time to download a fully functional 30 day evaluation and play with these packages. Feel free to give me a call if you have any questions or would like an on-line presentation.

Joe Brouwer |

TECH-NET ASSOCIATES | RENDERING OF THE MONTH | CAD•CAM SERVICES

HARDWARE | TECH TIPS | EMPLOYMENT | CONTACT