|

Solidworks Totally Misunderstands MBD | |

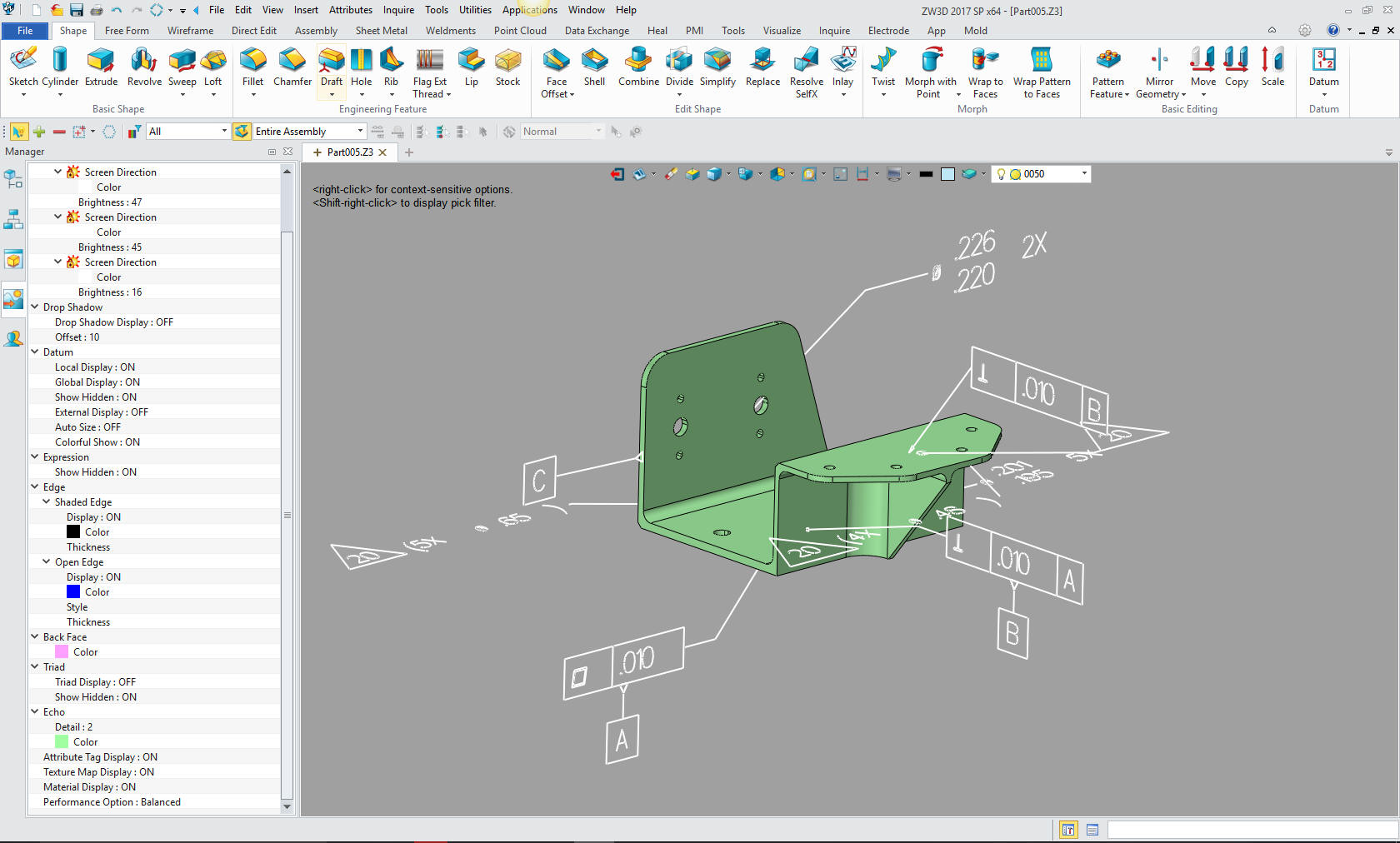

"For decades and decades the engineering process was developed by those that used it. Today, it is being developed by those outside the industry that develop processes that they "think" how it should work." This is a PMI (Product Manufacturing Information). One small question "When checking: How do you markup a PMI?" PMI vs AID (Associated Information Document)

Here is the original interview SOLIDWORKS Shorts: Model Based Definition (MBD) and Engineering 4.0What do you think Mr. Wu means? Decades ago we worked with 3D wireframe models and place the views for the AIDs in 3D space put in a document format and compress the graphics to a 2D plane, but this was 31 years ago. Surly Mr. Wu must know that Solidworks has a documentation module that creates the AID (Associated Information Document) is delivered as a PDF along with the 3D model in a native or neutral format. We have been doing this for 30 years. That is the advantage of 3D, simple to create documentation. In the early 1990s we were already delivering 3D models to manufacturing with complete documentation, I hate the word "2D Drawings", these were AIDs (Associated Information Documents). We would deliver 3D wireframe and surfaced parts by IGES. In 1995, solid modeling became available on the PC with CADKEY, Solidworks, IronCAD and all of the high end systems. We were then delivering solid models with IGES and STEP files. By 2000 all 3D CAD was on the PC, and many mid ranged programs could read the native files of all the popular programs. The high end systems dragged their feet trying to keep their users locked into their software. I think Catia still only exports IGES and STEP and it is optional. It is like having to order a steering wheel for a car. Catia is used by large companies with thousands of suppliers? How did they think they would talk to them? The 2000's - The Age of 3D CAD Un-Enlightenment! Talking to Catia! and other Popular 3D CAD Packages The above video was done in January 2015 not, 1990 or even 1995 with the release of Solidworks and a variety of other PC base and high end solid modeling systems. The 3D model was used as a pattern for manufacturing and as a .stl for stereolithography, 3D printing and images. The PDF was now widely available and we were then sending zip files with the 3D model in a native or neutral format and the AID as a PDF. This still is the most popular way of delivering the engineering documentation. Only the largest companies have enough money to waste on the failed PLM, MBE, MBD and PMI. Is the reason for this ignorance on one end or the other? Don’t the manufacturers know enough to ask for the 3D model? Don’t the design firms realize that is the reason they are designing in 3D. The comment strains all credulity.

Here is my response to Mr. Wu.

“The engineering world has been based on the 3D model for over 33 years. It

is shocking to think that someone still thinks we use drawings only as the

authorizing document. It has been the solid model “and” an AID (drawing) (first

printed and now delivered as a PDF) for me since 1987. Mr. Wu is describing MBD for SW. He thinks that we do not deliver a 3D model along with the drawings. He thinks we only give manufacturing the drawings and they have to recreate the 3D model. Sadly, this the level of ignorance that is managing the MBD process for Dassault. The AID (Associated Information Document (drawing)) is an easily generated reference document that requires no special software to view.”

Here is his response.

I

"Thanks for

the comment, Joe. Sorry for my late reply. Great to see you are interested in MBD

too. Yes, 2D drawing and 3D model have been a

mix together in the

I have been actually been doing this for 33 years and this guy is going to

explain it to me?

To prove the above statement, Dassault has an electronic drawing program call Draftsight to do real "2D drawings". Mr. Wu has had to learn about all of this from who? This was a study that was done by those with a vested interest and a defined outcome. This is a study that was sponsored by Siemens and Dassault Solidworks. Oh yes, we all know we can trust Siemens, Dassault and Solidworks to be concerned with our best interest. Who is Geometric? Oh, yes another company that benefits if we all move to MBD. MBE Model Base Enterprise is the name of this

process.

"2. In the mixed usage of 2D drawing and 3D model, the key question is: when there is a conflict between 2D and 3D, which one is taken as the authority? In a SOLIDWORKS base survey in 2014, 1/3 still respects 2D as the master over 3D. The good news is 2/3 take 3D as the authority (Sample size: 486), which is actually already level 1 or 2 per the NIST MBE Capabilities Assessment and lays a very solid foundation for Model-Based Enterprise (MBE).Why d This concept offers a check on the part. If there is a difference the design group should be contacted.

It is directly used as the pattern.

The "drawing" is

an AID (Associated Information Document). Truly, in today's 3D CAD

world it is not

designed to stand alone, even though it can in many cases. If there is a

discrepancy between the model and the documentation we have to go

back to the original designer for clarification. He/she will then

correct the model or documentation. But they are wasting their time. Engineering today is not managed by the knowledgeable engineering of the past. It is managed by PLM and InfoTech experts that have never sized a hole for a screw. Much less read or understand a drawing or a PMI for that matter.

Engineering Documentation - A Primer for the PLM Guru!

Again he has a complete misunderstanding of the process.

3. Now regarding

recreating 3D models per 2D drawings, in the same 2014 State Of Model Based

Enterprise Report by Lifecycle Insights, it found out that 40% downstream

procedures and suppliers have to recreate 3D models (Sample size: 575). Again he references a report written by a group that has a vested interest in promoting MBE. Lifecycle insights are run by a bunch of PLM gurus with no applicable engineering experience and cater to the major CAD vendors. This is 2014? I just cannot believe that 40% of the

industry can be this ignorant. Again, if he went out and visited the Solidworks users he would have found this out. But remember only machined

parts and sheet metal use the 3D model. Most fabrication, that use other

purchased compoments rarely even need a 3D model. The model is used to create the

documentation to define the cuts on tubing, wood and other standard shapes. I have been hired to create the 3D parts of a propeller for a torpedo, because they couldn’t find a machine shop that would not do it from the drawing and demanded a 3D model. "4. Onto your last point “drawing is an easily generated reference document that requires no special software to view.” Drawing may be easy to generate on an individual basis, but when it comes to massive amount of documents to create, update, and manage, drawing is not so easy. In an MBE conference 2 years ago, a representative of U.S. Department of Defense estimated 1/3 of their engineering dollars were spent in creating and maintaining 2D drawings, yet 60% of them didn’t match 3D design. These numbers are confirmed by several other enterprises. As to “no special software to view” drawings, if you referred to paper copies, that’s true, but that adds to the manufacturing overhead. Sometimes the paperwork to define a ground combat vehicle is even heavier than the tank itself; If you referred to 2D drawings PDF, then the same holds true to MBD deliverable. SOLIDWORKS MBD can generate PDF with dynamic 3D content such as models, dimensions, tolerances, bill of materials, customer properties… All needed is a free Adobe Reader to view the 3D content, which is already installed on 93% of internet-connected computers." Why MBE/MBD/PMI Will FAIL PART I Just because the AIDs (drawings) require synchronization, you don't throw out the baby with the bath water? How do they know whether the model or the documentation is correct? Initial release is a review of the document only, how do you do it with the model even if you have the obscure PMI. It is the proof of the part. When making changes you need the document to record the changes. It is a step in engineering to assure a defined path for any future problems. I am sure in the future Boeing will have huge problems working with the PMIs. Also how do you mark up a PMI? But this shows his complete lack of understanding about engineering documentation. With the elimination of the draftsman, engineers are moving into the position of delivering the engineering documentation. An AID (Associated Information Document) is very easy to generate. They are not aware the delivering concise, complete and unambiguous documentation to manufacturing is its only purpose.

Engineering’s only purpose is to make available concise, complete The Death of the Draftsman or “Where has all the talent gone?” Educating the New 3D CAD Engineer A single drawing like document delivered as a PDF and the model delivered in a usable format is the ultimate engineering deliverable. I takes no special software to read and it is easy to store and be available to the other departments in the company. What do they mean by paper? The documentation is stored as a PDF. Yes, manufacturing, purchasing, engineering and legal may print them, but only to work with them not to store them. It is surely better than looking at a computer screen for your specs. Also if you follow through the way Solidworks is presenting the PMI it is supported with a set of different confusing forms instead of an easy to view "drawing" like standard PDF document. That is where this all falls apart each CAD system has its own unique engineering documentation solution. It is a bit strange that Dassault keeps Catia and Solidworks completely separate. You would have thought they would have tried to merge the two products years ago. NX has the same problem with Solid Edge. Update 8/7/2019 SOLIDWORKS World is changing. In 2020, the event will be known as 3DEXPERIENCE World. We really need to get the engineering documentation deliverable out of the native CAD system.

Creating a completely defined document from the 3D model is very simple. It gives the designer a second look at the design for errors or even a better design. It is in a user-friendly format for design review and checking. It provides a document that can be viewed and understood by anyone with an engineering back ground. I even believe we could make these documents more informative. They are delivered in the convenient flexible PDF.

Mr. Wu has never done a drawing or even a 3D model. Yes, he has incredible

academic credentials. But mostly in software assurance. Why would they put a

fellow with virtually no hands on experience in engineering documentation in

such a position. He has no clue what is important and what is not important

except for reading some obscure studies.

All engineering documentation was

I have spent many years in drafting rooms and I never saw one MSME or PHD.

This guy is from Harvard. Harvard? I never met anyone from Harvard. We did

have a few P.E.s, they walked on water, they were there to bless our project.

As for delivering a special PDF as your engineering documentation, that is very time consuming. You

would have to create a special pdf for every part.

Every time you send something out

for quote you have to generate a PDF. That is why NIST, in the following

article, is trying to figure a way to read each of the major 3D CAD programs

native files with PMI.

MBE PMI Validation and Conformance Testing Project

This article shows the complete lack of

understanding of the simplicity of the "drawing", much less than the

concept of the model and PDF associated information document. So, there you go. Is Solidwork really

delivering a viable solution or just going along with the flow to promote a

virtually unworkable solution locking its users into their product.

Here is a comment by one of my Linkedin contacts that is forced to work with MBD. "The big problem is, any failure will be blamed on the responsible engineers and not an unworkable system. MBE is already being backstopped by drawings in many organizations that are forced to use MBE, but the drawings are frequently not in the release control process because they are not the "primary" data driving fabrication. A fine mess.." It is time to put engineering back in charge of engineering!

Now this leads me to these articles.

Engineering

Ignorance Defined II

TECH-NET Engineering Services!

|

TECH-NET ASSOCIATES | RENDERING OF THE MONTH | CAD•CAM SERVICES

HARDWARE | TECH TIPS | EMPLOYMENT | CONTACT