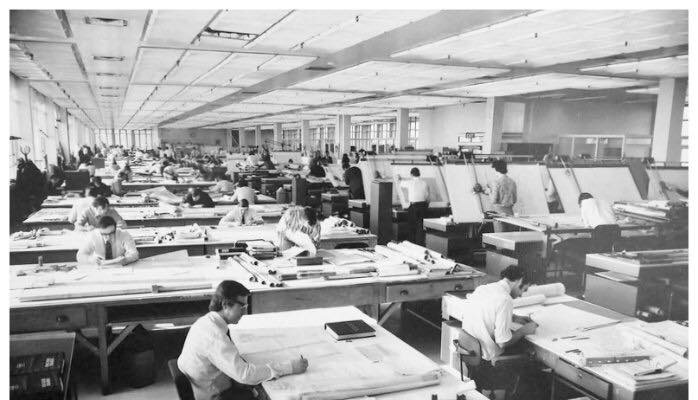

This is a drafting room. No, it was not called the engineering room. Drafting was the basis of all engineering. What you see here is the draftsmen on the right and the design engineers on the left. The two fellows close by could be stress, material or lead engineers or supervisors that over looked the drafting room. All engineers wore ties as did many of the older draftsmen. Rarely did you find an engineer on the drafting board. As draftsmen we were responsible for most of the Form, Fit and Function design. Many were in lead engineer positions that basically managed the different assignments or projects. Draftsmen made all of the drawings, even when 3D CAD was introduced. The 1980's - 3D CAD - The Beginning Engineers were not at the forefront of the FFF design, but were responsible for scrutinizing and assuring the design was feasible and would not fail. They were engineers not draftsman. My First 17 Years or "How did we do it without 3D CAD!" | |

|

The Drawing was Engineering's Language! The Drafting Group was dissolved at Boeing around the

turn of the century with the implementation of PLM. The Drafting Group was

made up of draftsmen which was an ancient mentoring profession. The Drafting Group The Drafting Group was responsible for the creation,

correctness, release and maintenance of the engineering drawing. It is a simple as that. Engineers had no position in a

drafting group. Yes, in smaller companies where the engineer was the chief cook and bottle washer

he would do

it all. But in large companies it was the Drafting Group in charge of the

engineering documentation.

Drawing Creation A few companies, like Pratt and Whitney had a design

department manned by engineers that created board design layouts. Now there might have been a few design

draftsman, but it was in a complete different building and I never was

there. They had a completely separate drafting group. In most

companies the draftsmen were assigned to specific engineering groups to work

alongside the design engineers. Draftsman working with the design engineer

or working alone would create the design layouts that were used to create

the drawings. There were design and drawing standards In each group a checker was assigned to review the

completed drawing. He/she would check for form, fit and function and drawing

correctness. He would sign off on the drawing in the title block as would

the draftsman, stress, materials, manufacturing and lead engineers, finally the

engineering supervisor. The Drawing was released to Document Control. With this many eyes on the design you could pretty much

be assured that the part was correct. But there is always the human factor.

Just one failed part can cause havoc at assembly Revisions If a part could not be installed a rejection tag or ECO (Engineering Change Order) would be generated by a Liaison Engineer and sent to the originating group. These were handled by the Drafting Group, investigated and working with a design or lead engineer solutions were implemented. The draftsman would document the change as a revision. These could be ADCNs (Advanced Drawing Change Notices) done on 8.5 x 11 sheets that would be printed and attached to the print or directly change the drawing with a DCN (Drawing Change Notice) There were no engineers involved in this process except

for support, review and sign off. What was the only media? THE

SINGLE DRAWING The 3D CAD Factor We will not concern ourselves with the CAD (Computer

Aided Drawing) these were electronic drawing packages, mostly Autocad, that created drawings

made up of unassociated orthographic views. They were plotted on vellum and

handled like the manual drawing. But 3D CAD was completely different, it was the end of

the "drawing" as we knew them. We now created documents by dimensioning views created from the

3D model. I have coined these AIDs (Associated Information Documents) One of the misnomers that came out of the transition from drawings to AIDs was "2D Drawing". This was used to describe any document that looked like a drawing whether created manually, electronically or by a 3D CAD documentation module. This generalization has led to many uninformed decisions on how the different documentation should be handled. With 3D CAD the documentation is created at the end of the

design in the documentation module, with the major CAD systems it is

added file that must be synchronized with and "travel" with the 3D model.

In the beginning of CAD the draftsman would do the

design and create the AID. The AID was plotted and released as a print. But the 3D

model was soon to be used as a pattern for CNC and drive a 3D printer, plus

many other purposes from inspection to marketing.

The 3D model and AID as a print became a nightmare for PDM and PLM. Then some brilliant people decided we needed one

document like the drawing was in the past and they developed MBE (Model

Based Enterprise) based on

the PMI (Product Manufacturing Information). Which you can only call a 3D drawing! This was a top down decision made by those with not one ounce of applicable knowledge of the engineering document control system. They replaced a standard system that was efficiently honed from the bottom up over decades if not centuries. A truly arrogant bunch! They still stand in the way of solving this chaos. They were not even curious enough to find how it was done in the past. E

Why MBE/MBD/PMI Will FAIL Part II Management thought with the PMI there was no need of conventional drawings,

therefore no need for

draftsmen.

Boeing eliminated the drafting and documentation control group. They even renamed the Draftsmen to Engineering Techs. Documentation was now managed by Dassault PLM! Can you imagine one of the greatest manufacturing companies in one of the most safety sensitive industries in the world handing their proven standard engineering management over to a CAD software company? This decision was incredibly irresponsible and

ignorant. Why did they get rid of the drafting group? It was the enemy of

Dassault, the InfoTechs and the new PLM gurus. The documentation was the

most important step in engineering and the Drafting Group was the watch dog.

They knew the process introduced by Dassault, the PLM gurus and InfoTechs led by the CIO would

cause chaos and fought them. But sadly, there

were no PHDs in Drafting just seasoned professionals.

So, who is in

charge of the documentation today? When Boeing got rid of the draftsmen, they handed all

of drafting’s responsibility to the degreed 3D CAD engineer without a

transition plan. I suppose they thought the “Engineering Techs” would

transfer their knowledge by osmosis before they were let go by attrition! The Millennial CAD engineer is now responsible for the

design, analysis, the creation of the documentation, the correctness of the documentation,

the form, fit and function of the design, the release of the d Today it is more important for an engineer to have the companies CAD system experience than industry related experience. Don’t believe me? Read this article very carefully!

Engineering Yesterday & Today They were to do this with not one drafting or engineering documentation training class in college. Prior to this situation, Boeing knew this and like most aerospace companies would start the new engineers in drafting under the guidance of the senior draftsmen for a year. Today there is no one group that is now responsible for the

engineering documentation it is just part of the 3D CAD engineers job.

I Engineering Documentation Today! There is no set training for engineering documentation today.

Most is learned on the job from those that learned it on the job.

Yes, we need a drafting group or a separate group that is

responsible for the engineering documentation Again I will state this and you should now realize why

engineering is in the condition it is.

Can we blame the elimination of the drafting group for the 737 Max failure plus many of other Boeing delayed projects and much of the state of the industry today? You be the judge! Please feel free to stop by our website below for a variety of articles on the State of our Industry, interesting articles on 3D CAD Productivity and a few of our projects!

TECH-NET Engineering Services! We sell and support IronCAD and ZW3D Products and

If you are interested in adding professional hybrid modeling capabilities or looking for a new solution to increase your productivity, take some time to download a fully functional 30 day evaluation and play with these packages. Feel free to give me a call if you have any questions or would like an on-line presentation. For more information or to download IronCAD or ZW3D Joe Brouwer |

TECH-NET ASSOCIATES | RENDERING OF THE MONTH | CAD•CAM SERVICES

HARDWARE | TECH TIPS | EMPLOYMENT | CONTACT